TMM4 High-Frequency PCB Properties Manufacturing and Applications

July 24, 2025

July 24, 2025

1.Introduction

Rogers TMM4 is a high-performance thermoset microwave material designed for high plated-through-hole reliability in strip-line and micro-strip applications. Combining the benefits of ceramics, hydrocarbons, and thermoset polymers, TMM4 offers superior mechanical and chemical properties without requiring specialized production techniques. Its thermoset resin base ensures reliable wire bonding, preventing pad lifting and substrate deformation.

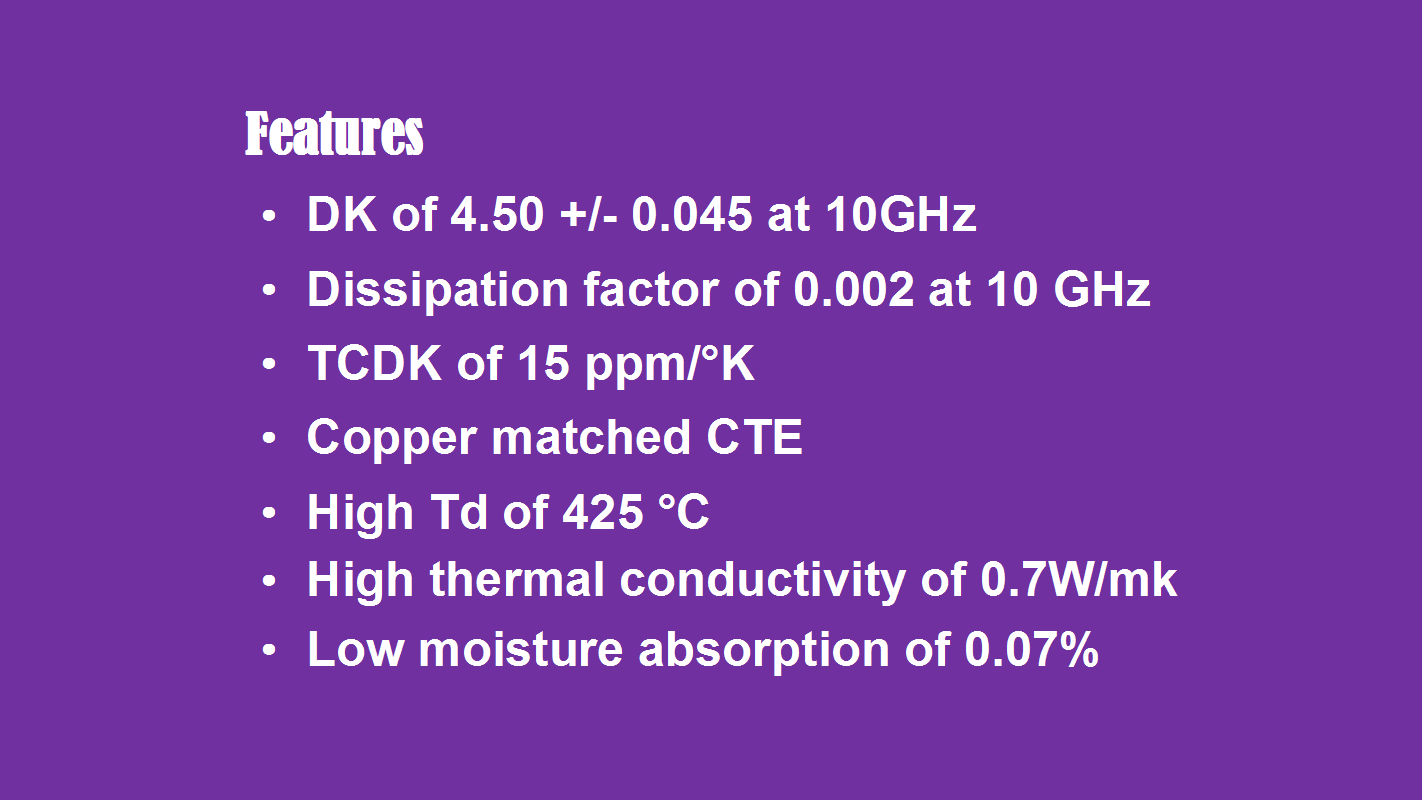

2.Key Features of TMM4 PCB Material

Dielectric Constant (Dk) 4.50 ± 0.045 (stable for high-frequency circuits)

Dissipation Factor (Df) 0.0020 @ 10GHz (low signal loss)

Thermal Coefficient of Dk 15ppm/°K (stable performance under temperature changes)

CTE Matched to Copper x/y = 16 ppm/°K, z = 21 ppm/°K (reduces thermal stress)

High Decomposition Temp (Td) 425°C (TGA) (excellent thermal stability)

Thermal Conductivity 0.7 W/mK (efficient heat dissipation)

Low Moisture Absorption 0.07% (50mil) & 0.18% (125mil) (resists humidity issues)

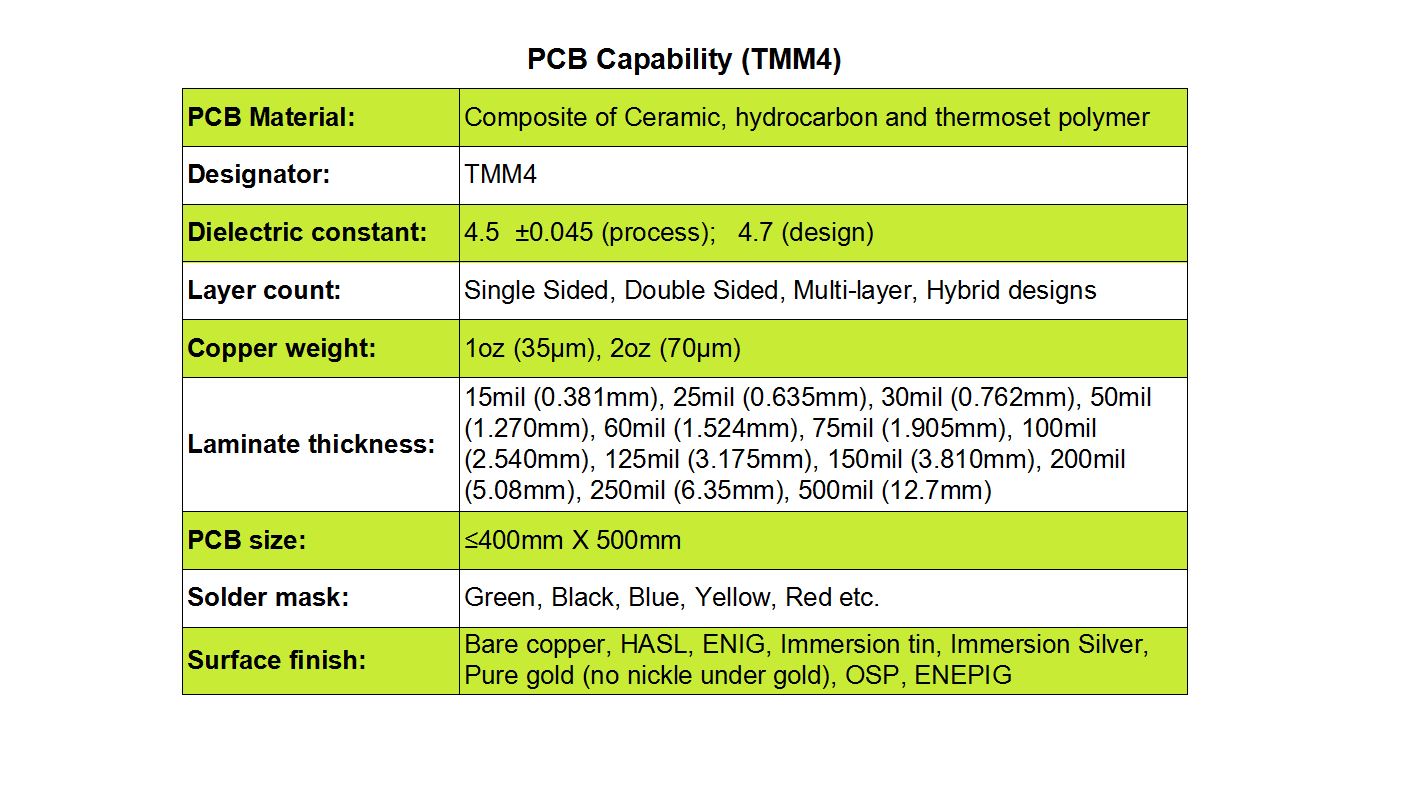

3.PCB Manufacturing Capabilities

Types Single-sided, double-sided, multilayer, hybrid PCBs

Copper Weights 1oz (35µm), 2oz (70µm)

Laminate Thickness 15mil (0.381mm) to 500mil (12.7mm)

Max PCB Size 400mm × 500mm

Solder Mask Colors Green, black, blue, yellow, red, etc.

Surface Finishes Bare copper, HASL, ENIG, immersion tin/silver, pure gold, OSP, ENEPIG

4.Applications

Power Amplifiers & Combiners

Filters & Couplers

Satellite Communication Systems

GPS Antennas & Patch Antennas

Chip Testers & High-Frequency Circuits