Wangling TF High Frequency PCBs Precision Engineered for Microwave and Millimeter Wave Applications

October 12, 2025

October 12, 2025

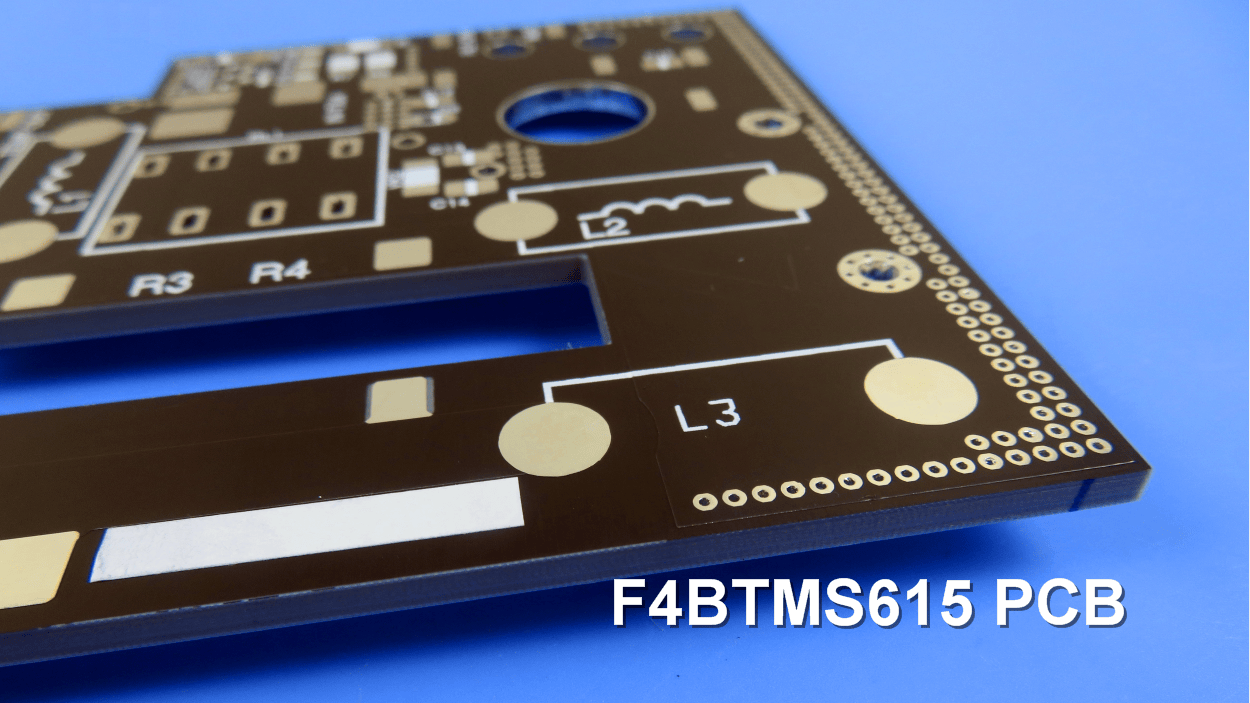

In the continuous pursuit of higher performance in RF and microwave design, material innovation remains paramount. The F4BTMS series represents a significant evolution of the established F4BTM laminates, incorporating advanced material science to push the boundaries of electrical performance, thermal management, and dimensional stability.

Engineered with a high ceramic content and ultra-thin, ultra-fine fiberglass cloth, F4BTMS is tailored for the most demanding high-frequency applications, from aerospace to advanced radar systems.

Introducing the F4BTMS Series

F4BTMS is a strategic upgrade to the F4BTM series, featuring a refined composition of special nano-ceramics, PTFE resin, and a meticulously selected glass reinforcement. This synergy delivers:

A broader range of tunable dielectric constants

Greatly reduced dielectric loss

Enhanced dimensional stability across all axes

Superior thermal performance

The result is a laminate that supports higher frequency operation, increased power handling, and improved reliability in critical environments.

Defining Features of F4BTMS

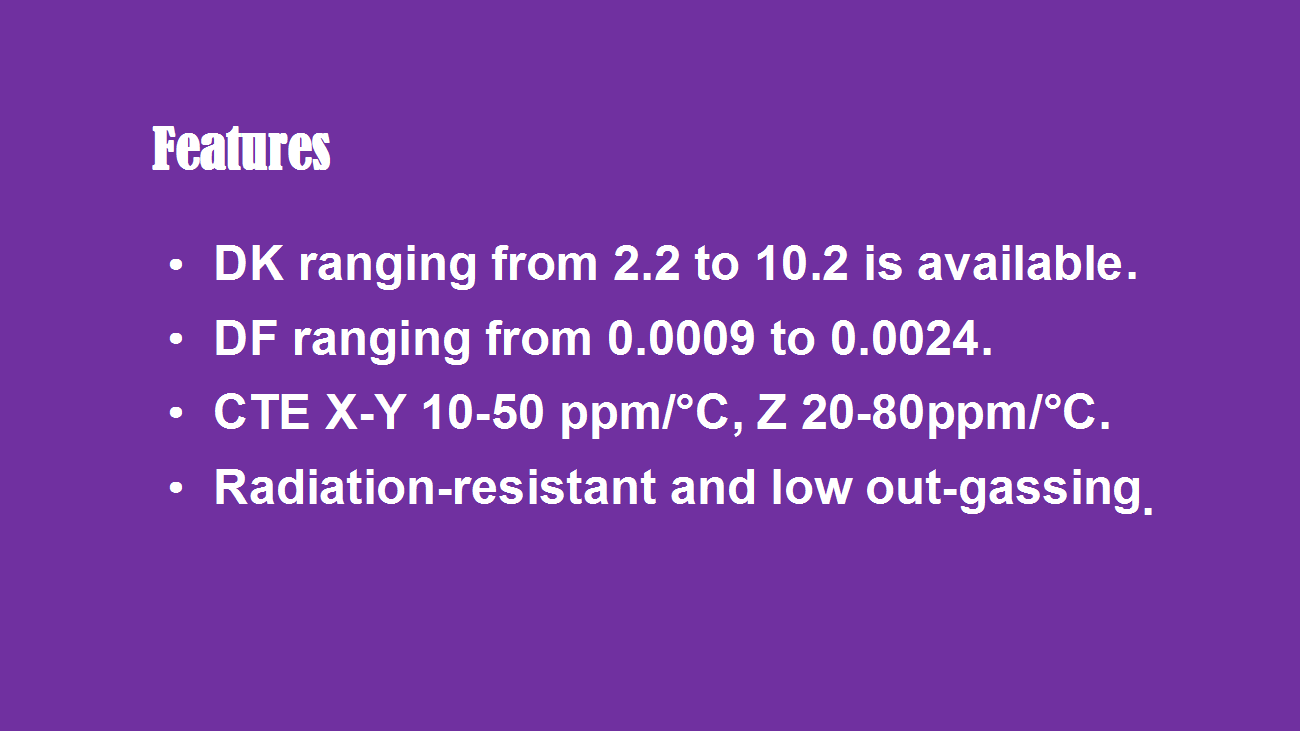

Wide & Stable Dk Range: From 2.2 to 10.2, offering exceptional design flexibility

Ultra-Low Loss Tangent: Ranging from 0.0009 to 0.0024 for minimal signal attenuation

Excellent Thermal Stability: Temperature coefficient of Dk (TCDk) within ±100 ppm/°C

Low CTE:

X/Y direction: 10–50 ppm/°C

Z-direction: 20–80 ppm/°C

Ensures reliable plated through-holes and dimensional integrity

Space-Grade Performance: Radiation-resistant and low outgassing, ideal for aerospace and vacuum environments

PCB Manufacturing Capabilities with F4BTMS

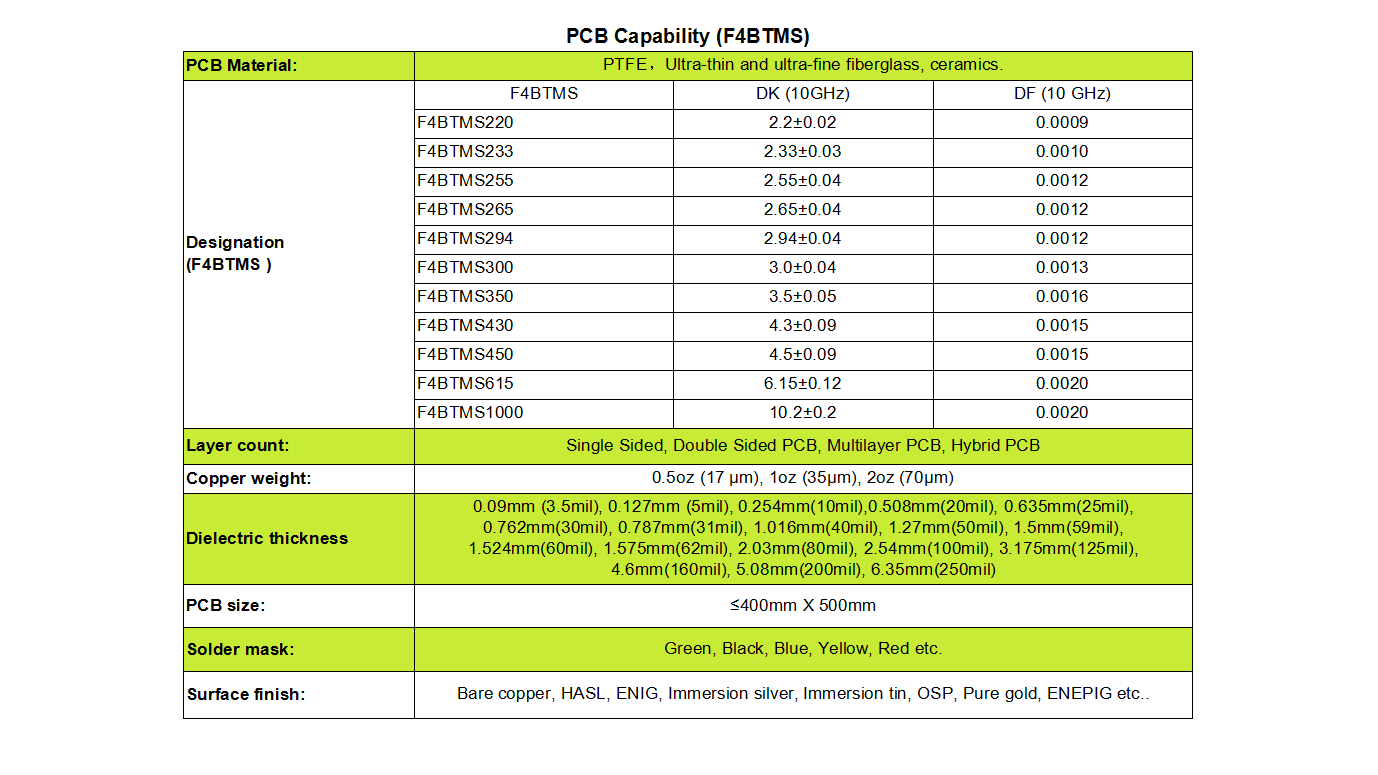

We support comprehensive fabrication options to meet diverse design requirements:

Layer Configurations: Single-sided, double-sided, multilayer, and hybrid builds

Copper Weight: 1 oz (35µm) and 2 oz (70µm)

Dielectric Thickness: From 0.09 mm (3.5 mil) to 6.35 mm (250 mil)

Max Board Size: Up to 400 mm × 500 mm

Solder Mask Colors: Green, black, blue, yellow, red, and more

Surface Finishes: ENIG, HASL, Immersion Silver, Immersion Tin, OSP, ENEPIG, Pure Gold, and bare copper

Common Applications

F4BTMS PCBs are ideally suited for high-reliability and high-frequency systems, including:

Aerospace and aviation electronics

Microwave and RF circuits

Radar systems (including phased array radar)

Signal distribution and feed networks

Phase-sensitive and phased array antennas

Why Upgrade to F4BTMS?

For designers pushing the limits of frequency, efficiency, and environmental resilience, F4BTMS offers a clear advantage over standard PTFE-based materials. Its lower loss, flatter thermal response, and robust mechanical properties make it an enabling technology for next-generation communication, sensing, and avionics systems.

Whether you are developing satellite payloads, defense radar, or high-speed wireless infrastructure, F4BTMS provides the material foundation for success.

Explore F4BTMS for Your Advanced Designs

Ready to leverage the enhanced performance of F4BTMS in your next project? Contact our engineering team to request datasheets, evaluate samples, or discuss your specific application needs.