18-Layer PCB with Premium RO4350B and RO4450F for Superior High-Frequency Performance

1. PCB Construction Details:

| Specification | Details |

|---|---|

| Base Material | RO4350B + RO4450F |

| Layer Count | 18 layers |

| Board Dimensions | 218 mm x 497 mm (1 PCS, +/- 0.15 mm) |

| Minimum Trace/Space | 4/4 mils |

| Minimum Hole Size | 0.4 mm |

| Blind Vias | L11-L18, mechanical drill |

| Finished Board Thickness | 3.2 mm |

| Finished Copper Weight | 1 oz (1.4 mils) for inner and outer layers |

| Via Plating Thickness | 20 µm |

| Surface Finish | Immersion Gold + Selective Hard Gold (50 microinches) |

| Top Silkscreen Color | White |

| Bottom Silkscreen Color | White |

| Top Solder Mask Color | Blue |

| Bottom Solder Mask Color | Blue |

| Via in Pad Required | Yes, press-fit holes required |

| All Vias | Resin filled and capped |

| Testing | 100% Electrical testing conducted prior to shipment |

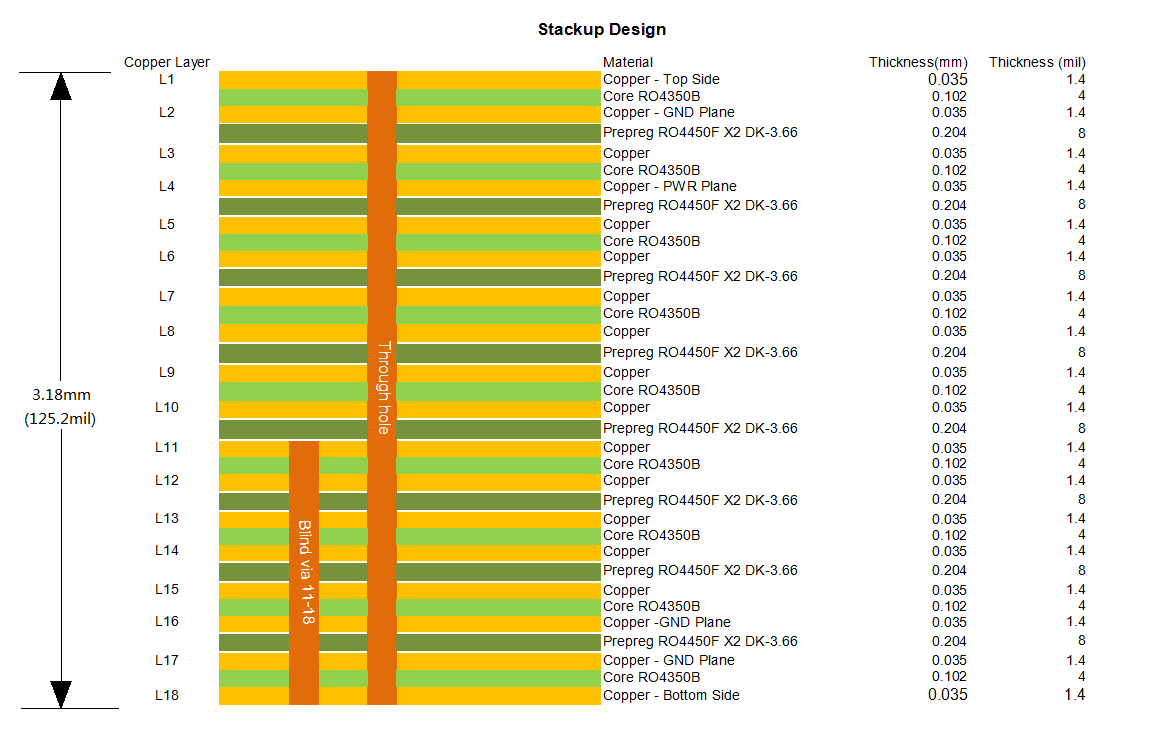

2. PCB Stackup: 18-layer Rigid PCB

3. PCB Statistics:

Components Count: 651

Total Pads: 779

Through Hole Pads: 338

Top SMT Pads: 262

Bottom SMT Pads: 179

Vias Count: 632

Nets Count: 12

4. Type of artwork supplied:

- Gerber RS-274-X

5. Quality standard:

- IPC-Class-2

6. Availability:

- Worldwide

7.Introduction to RO4350B Core and RO4450F Bondply:

Rogers RO4350B materials are proprietary woven glass reinforced hydrocarbon/ceramics that offer electrical performance similar to PTFE/woven glass while maintaining the manufacturability of epoxy/glass. RO4350B laminates ensure tight control over dielectric constant (Dk) and exhibit low loss, utilizing standard epoxy/glass processing methods. These materials are available at a fraction of the cost of traditional microwave laminates and do not require special through-hole treatments or handling procedures like PTFE-based materials. They are UL 94 V-0 rated for active devices and high-power RF applications.

The thermal coefficient of expansion (CTE) of RO4350B material closely matches that of copper, providing excellent dimensional stability, essential for mixed dielectric multi-layer constructions. The low Z-axis CTE ensures reliable plated through-hole quality, even under severe thermal shock conditions. RO4350B material has a glass transition temperature (Tg) of over 280 °C (536 °F), maintaining stable expansion characteristics throughout the entire range of circuit processing temperatures.

RO4450F bondplys are compatible with multi-layer constructions involving RO4000 laminates. A high post-cure Tg makes RO4450F bondply an ideal choice for multi-layer assemblies requiring sequential laminations. Fully cured RO4450F bondplys can withstand multiple lamination cycles. Additionally, FR-4 compatible bonding requirements allow for the combination of RO4450F bondply and low-flow FR-4 bondply in non-homogeneous multi-layer constructions using a single bonding cycle.

RO4450F bondplys are compatible with multi-layer constructions involving RO4000 laminates. A high post-cure Tg makes RO4450F bondply an ideal choice for multi-layer assemblies requiring sequential laminations. Fully cured RO4450F bondplys can withstand multiple lamination cycles. Additionally, FR-4 compatible bonding requirements allow for the combination of RO4450F bondply and low-flow FR-4 bondply in non-homogeneous multi-layer constructions using a single bonding cycle.

8. Features of RO4350B:

Dielectric Constant: Dk 3.48 ±0.05 at 10 GHz/23 °C

Dissipation Factor: 0.0037 at 10 GHz/23 °C

Thermal Conductivity: 0.69 W/m/°K

X-axis CTE: 10 ppm/°C, Y CTE: 12 ppm/°C, Z CTE: 32 ppm/°C

High Tg Value: >280 °C

Low Water Absorption: 0.06%

9. Features of RO4450F:

Dielectric Constant: Dk 3.52 ±0.05 at 10 GHz/23 °C

Dissipation Factor: 0.004 at 10 GHz/23 °C

Thermal Conductivity: 0.65 W/m/°K

X-axis CTE: 19 ppm/°C, Y CTE: 17 ppm/°C, Z CTE: 50 ppm/°C

Typical Applications:

Cellular Base Station Antennas and Power Amplifiers

RF Identification Tags

Automotive Radar and Sensors

LNBs for Direct Broadcast Satellites