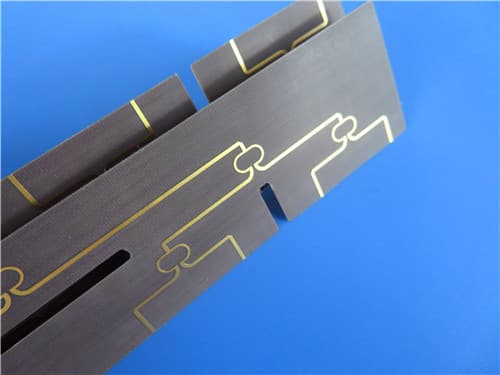

F4BM217 2-Layer 3.9mil Ultra-Thin PTFE PCB with Immersion Gold

1.Introduction

Wangling's F4BM217 laminates are made by scientifically formulating and strictly pressing a combination of fiberglass cloth, polytetrafluoroethylene resin, and polytetrafluoroethylene film. Its electrical performance is improved compared to F4B220, mainly due to lower dielectric loss, increased insulation resistance, and improved stability. It can replace similar foreign products.

F4BM217 and F4BME217 have the same dielectric layer but different copper foil combinations: F4BM217 is paired with ED copper foil, suitable for applications without PIM requirements; F4BME217 is paired with reverse-treated foil (RTF) copper foil, offering excellent PIM performance, more precise line control, and lower conductor loss.

By adjusting the ratio between polytetrafluoroethylene and fiberglass cloth, F4BM217 and F4BME217 achieve precise control of the dielectric constant, providing low loss and enhanced dimensional stability. A higher dielectric constant corresponds to a higher proportion of fiberglass, resulting in better dimensional stability, lower thermal expansion coefficient, improved temperature drift, and a slight increase in dielectric loss.

2.Key Features (F4BM217)

Dielectric constant (Dk) of 2.17±0.04 at 10GHz

Dissipation factor of 0.001 at 10GHz

CTE x-axis of 25 ppm/°C, CTE y-axis of 34 ppm/°C, CTE z-axis of 240 ppm/°C, -55°C to 288°C

Thermal coefficient of Dk at -150 ppm/°C, -55°C to 150°C

Moisture absorption of ≤0.08%

Flammability of UL-94 V0

3.Benefits

Improved electrical performance compared to F4B220

Can replace similar imported PTFE laminates

Suitable for non-PIM applications (ED copper foil version)

Enhanced dimensional stability with precise Dk control

Low loss with good insulation resistance

UL-94 V0 flame retardant rating

4.PCB Details

| Specification | Value |

|---|---|

| Base Material | F4BM217 |

| Layer Count | double sided |

| Board Dimensions | 120mm × 89mm (±0.15mm) |

| Minimum Trace/Space | 6/7 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 0.17mm |

| Finished Cu Weight (Outer Layers) | 1oz (1.4 mils) |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | No |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Test | 100% prior to shipment |

5.PCB Stackup (2-Layer Rigid Structure)

Copper layer 1 – 35 μm

F4BM217 Core – 0.1 mm (3.9mil)

Copper layer 2 – 35 μm

6.PCB Statistics

Components: 5

Total Pads: 21

Thru Hole Pads: 15

Top SMT Pads: 6

Bottom SMT Pads: 0

Vias: 25

Nets: 2

7.Typical Applications

Microwave, RF, and radar systems

Phase shifters

Passive Components

Power dividers, couplers, combiners

Feed networks

Phased array antennas

Satellite communications

Base station antennas

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide