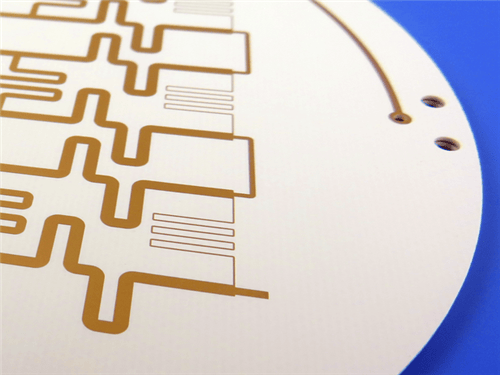

Kappa 438 2-Layer 60mil PCB – ENIG Finish, FR-4 Compatible High-Frequency Material for 5G & IoT Applications

1.Kappa 438 Introduction

Rogers Kappa 438 laminates are designed using a glass-reinforced hydrocarbon ceramic system that offers superior high-frequency performance and low-cost circuit fabrication. This results in a low-loss material that can be fabricated using standard epoxy/glass (FR-4) processes. Kappa 438 laminates also have the UL 94 V-0 flame retardant rating and are compatible with lead-free solder processes. Standard thicknesses include 10, 20, 30, 40, and 60 mil.

Kappa 438 laminates offer dielectric constants (Dk) tailored to FR-4 industry standard norms, facilitating ease of converting existing FR-4 designs where better electrical performance is needed.

2.Key Features

Glass-reinforced hydrocarbon thermoset platform

Dk of 4.38 tailored to FR-4 industry standard norms

Tighter Dk and thickness tolerance than FR-4

Low Z-axis CTE of 42 ppm/°C

High Tg of >280°C (TMA)

Thermal coefficient of Dk: -21 ppm/°C (-50°C to 150°C)

Meets UL 94-V0 requirements

3.Benefits

Ease of PCB manufacturing and assembly in line with FR-4 processes

Design Dk enables easy conversion of existing FR-4 designs needing better electrical performance

Consistent circuit performance

Improved design flexibility and plated through-hole reliability

Automated assembly compatible

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | Kappa 438 |

| Layer Count | 2 layers |

| Board Dimensions | 53mm × 36mm (±0.15mm) |

| Minimum Trace/Space | 4/4 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 1.6mm |

| Finished Cu Weight | 1 oz (1.4 mils) outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | Electroless Nickel Immersion Gold (ENIG) |

| Top Silkscreen | Black |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (2-Layer Rigid Structure)

Copper_layer_1 - 35 μm Rogers Kappa 438- 1.524 mm (60mil) Copper_layer_2 - 35 μm

6.PCB Statistics:

Components: 10

Total Pads: 34

Thru Hole Pads: 22

Top SMT Pads: 12

Bottom SMT Pads: 0

Vias: 27

Nets: 2

7.Typical Applications

Carrier Grade WiFi/Licensed Assisted Access (LAA

Small Cell and Distributed Antenna Systems (DAS)

Vehicle to Vehicle/Vehicle to Infrastructure Communications (V2X)

Internet of Things (IoT) Segments: Smart Home and Wireless Meters

8.Quality Assurance

IPC-Class 2 compliant

100% electrical tested

Global availability

Gerber RS-274X support