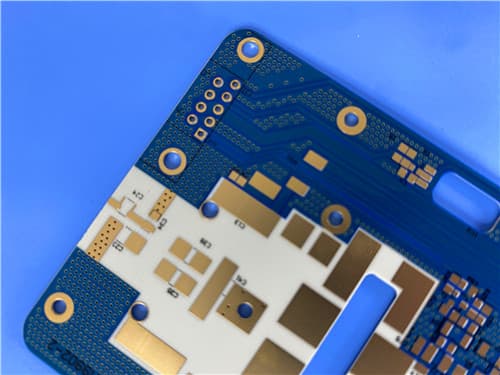

RO3206 2-Layer 25mil PCB – Ceramic-Filled Woven Glass RF Substrate with Immersion Gold for Automotive & Wireless Systems

1.Introduction of RO3206

Rogers' RO3206 high frequency circuit materials are ceramic-filled laminates reinforced with woven fiberglass. These materials are engineered to offer exceptional electrical performance and mechanical stability at competitive prices. The RO3206 high frequency materials were designed as an extension of the RO3000 series high frequency circuit materials with one distinguishing characteristic - improved mechanical stability.

2.Key Features

Dielectric constant of 6.15 ±0.15 at 10 GHz/23°C

Dissipation factor of 0.0027 at 10GHz

High Thermal conductivity of 0.67 W/mK

Low Moisture Absorption < 0.1%

CTE matched to copper: X-axis 13 ppm/°C, Y-axis 13 ppm/°C, Z-axis 34 ppm/°C

Strong copper peel strength of 10.7 lbs/in

3.Benefits

Woven glass reinforcement improves rigidity for easier handling

Uniform electrical and mechanical performance ideal for complex multi-layer high frequency structures

Low dielectric loss ensures high frequency performance

Low in-plane expansion coefficient matched to copper

Suitable for use with epoxy multilayer board hybrid designs

Reliable surface mounted assemblies

Excellent dimensional stability ensures high production yields

Economically priced for cost-effective volume manufacturing

Surface smoothness allows for finer line etching tolerances

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | RO3206 |

| Layer Count | 2-layer |

| Board Dimensions | 63mm × 45mm (±0.15mm) |

| Minimum Trace/Space | 4/4 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 0.75mm |

| Finished Cu Weight | 1oz (1.4 mils) outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | No |

| Top Solder Mask | Blue |

| Bottom Solder Mask | No |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (2-Layer Rigid Structure)

Copper_layer_1 - 35 μm

RO3206 - 0.635 mm (25mil)

Copper_layer_2 - 35 μm

6.PCB Statistics:

Components: 21

Total Pads: 43

Thru Hole Pads: 25

Top SMT Pads: 18

Bottom SMT Pads: 0

Vias: 22

Nets: 2

7.Typical Applications

Automotive collision avoidance systems

Automotive global positioning satellite antennas

Wireless telecommunications systems

Microstrip patch antennas for wireless communications

Direct broadcast satellites

Datalink on cable systems

Remote meter readers

Power backplanes

LMDS and wireless broadband

Base station infrastructure

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide