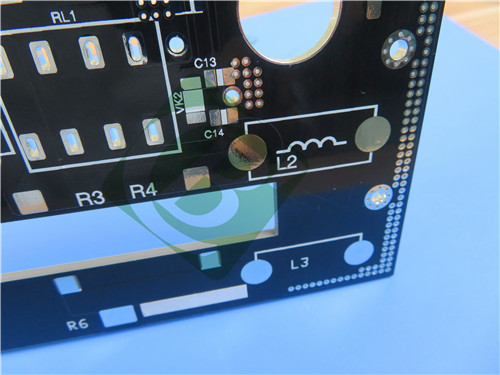

Rigid Polyimide 4-Layer PCB 1.8mm Thick with HASL Lead-Free Finish for High-Temperature Applications

1.Introduction to Rigid Polyimide Material

Polyimide is a high-performance polymer known for its outstanding thermal stability, mechanical strength, and electrical insulation. It maintains exceptional peel strength (1.42 N/mm after thermal stress, 1.13 N/mm after process exposure) and superior electrical properties (volume resistivity: 6.6×10? MΩ·cm under C-96/35/90 conditions). With a dielectric constant of 4.12 and dissipation factor of 0.0072 at 1MHz, polyimide excels in high-frequency applications. Its moisture resistance (0.11% absorption), high dielectric strength (44.3 kV), and thermal resilience (no delamination at 288°C, Tg 257°C) make it indispensable for aerospace, military, and high-temperature environments.

2.Features

Thermal Stability: Tg of 257°C, withstands 288°C thermal stress.

Mechanical Strength: Bending strength of 410.2 N/mm² (machine direction).

Electrical Performance: Volume resistivity of 6.6×10? MΩ·cm, dielectric constant of 4.12.

Moisture Resistance: 0.11% absorption rate.

High-Frequency Suitability: Low dissipation factor (0.0072 at 1MHz).

3.Benefits

Reliability: Maintains performance in extreme temperatures and harsh conditions

Durability: Excellent peel strength and mechanical robustness.

Electrical Integrity: Stable dielectric properties for high-frequency applications.

Versatility: Suitable for aerospace, military, and industrial uses.

4.PCB Construction Details

| Specification | Technical Details |

|---|---|

| Base Material | Rigid Polyimide |

| Layers | 4 |

| Board Dimensions | 325×83mm (±0.15mm) |

| Trace/Space | 5/5 mils |

| Min. Hole Size | 0.3mm |

| Board Thickness | 1.8mm |

| Copper Weight | 1oz outer layers (35μm) |

| Via Plating | 20μm |

| Surface Finish | Lead-free HASL |

| Silkscreen | White (both sides) |

| Solder Mask | Black (both sides) |

| Via Treatment | 0.3mm resin-filled & capped |

| Countersink Holes | Top side |

| Electrical Test | 100% tested |

5.PCB Stackup (4-Layer Rigid Structure)

Copper layer 1 - 35 μm

Polyimide Core - 0.32 mm

Copper layer 2 - 35 μm

Polyimide Prepreg - 0.1mm

Polyimide Core - 0.8mm

Polyimide Prepreg - 0.1mm

Copper layer 3 - 35 μm

Polyimide Core - 0.32 mm

Copper layer 4 - 35 μm

6.PCB Statistics:

Components: 68

Total Pads: 102

Thru Hole Pads: 47

Top SMT Pads: 39

Bottom SMT Pads: 16

Vias: 121

Nets: 12

7.Typical Applications

Aerospace and aviation electronics

Military equipment

Downhole oil extraction systems

High-temperature industrial applications

8.Quality Assurance

IPC-Class 2 compliant

100% electrical tested

Global availability

Gerber RS-274X support