CLTE-XT Laminates Deliver Superior Performance for RF and Microwave Designs

September 23, 2025

September 23, 2025

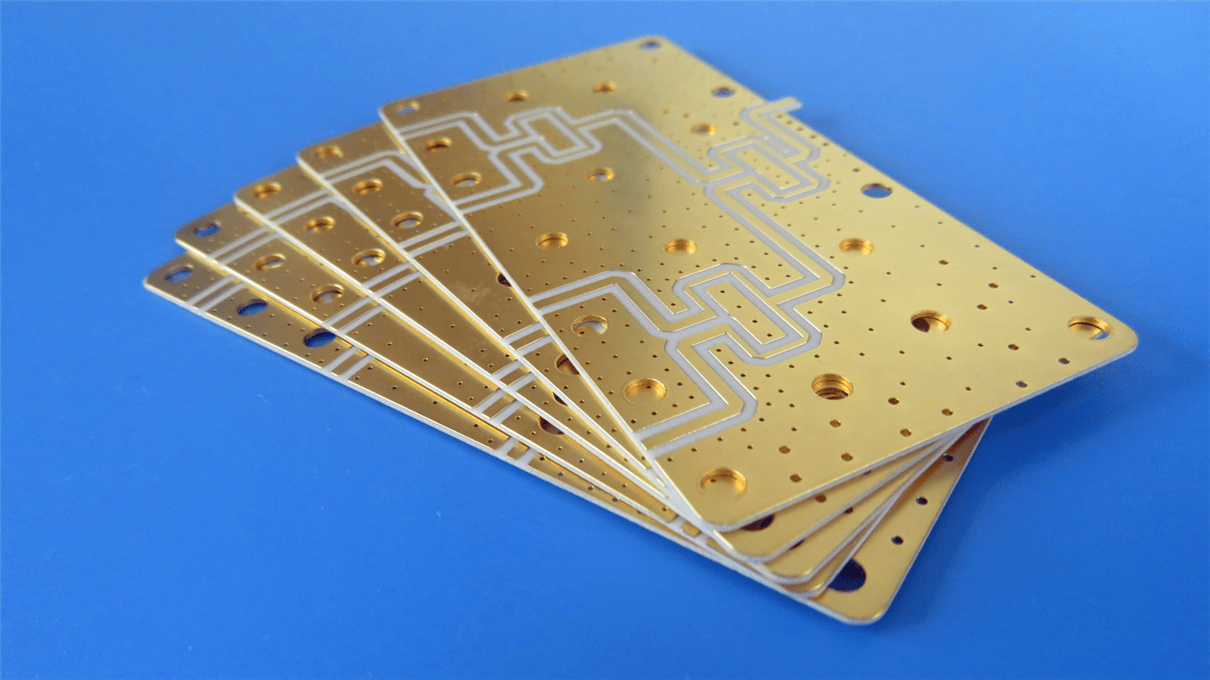

In high-frequency circuit design, every detail matters—especially the substrate. Rogers CLTE-XT stands out as a high-performance laminate engineered for applications where signal integrity, thermal stability, and precision are non-negotiable.

Ideal for RF and microwave systems, CLTE-XT combines ceramic-filled PTFE with woven fiberglass reinforcement, delivering exceptional electrical and mechanical performance. Let’s explore what makes this material a top choice for advanced electronics.

What Is CLTE-XT?

CLTE-XT is a Rogers laminate designed to offer improved loss tangent while maintaining excellent dimensional stability. It features a micro-dispersed ceramic and PTFE composite with woven glass support, providing one of the lowest performance variances among PTFE-based materials on the market.

It also supports a wide range of metal cladding options, including:

Electrodeposited copper

Reverse treated foil

Rolled copper

Other specialty conductors

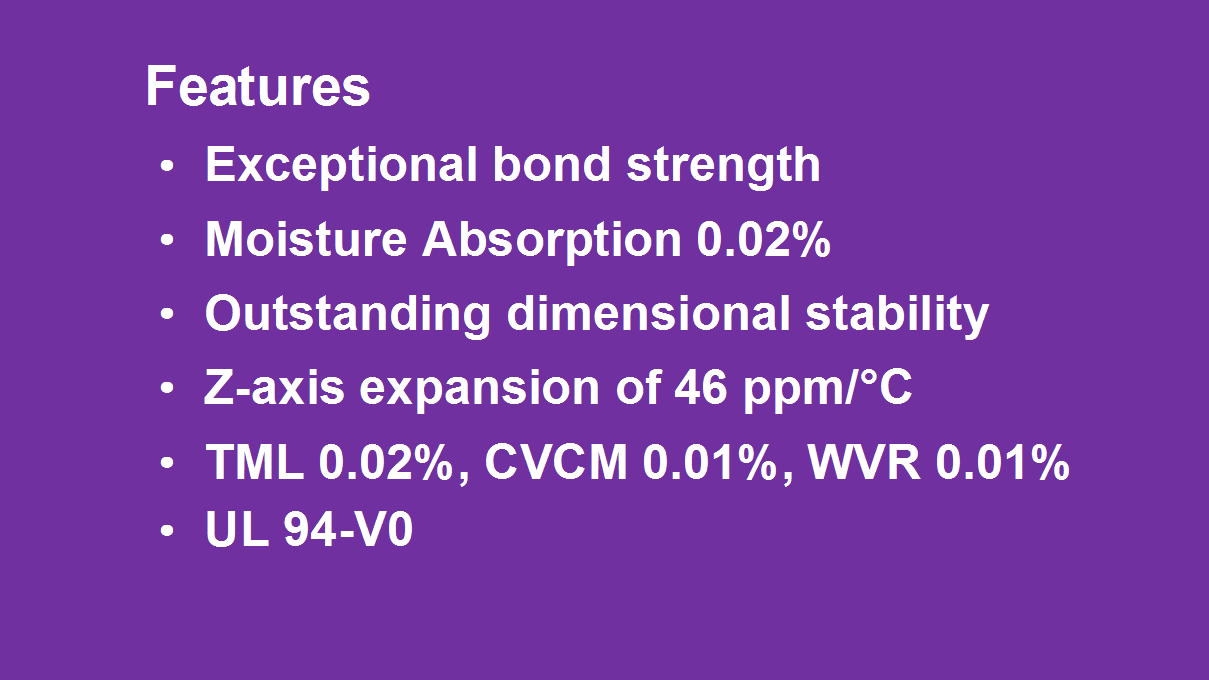

Key Features of CLTE-XT

1.Ultra-Low Dissipation Factor

With a loss tangent of just 0.0010 at 10 GHz, CLTE-XT minimizes circuit losses—ideal for high-speed and high-frequency designs.

2.Excellent Dimensional Stability

The laminate offers one of the lowest planar CTEs among PTFE materials, making it suitable for precision applications like embedded resistors.

3. Low Z-Axis CTE (20 ppm/°C)

This ensures high reliability of plated through-holes, even under repeated thermal cycling.

4.Stable Dielectric Constant

A tight tolerance of ±0.03 across temperature variations ensures consistent impedance control and minimal signal distortion.

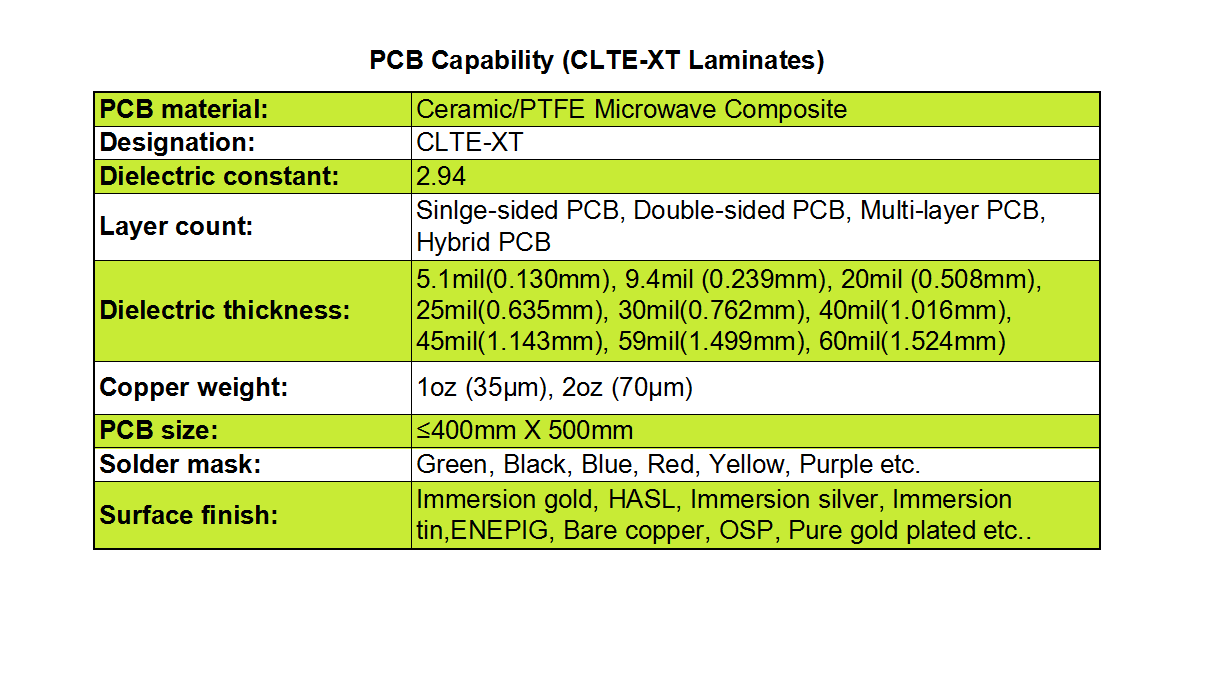

PCB Manufacturing Capabilities

We provide full manufacturing support for CLTE-XT PCBs in various configurations:

Layer Types: Single-layer, double-layer, multilayer, and hybrid builds

Dielectric Thickness: 0.130mm (5.1 mil) to 1.524mm (60 mil)

Copper Weight: 1 oz (35µm) or 2 oz (70µm)

Max. Panel Size: 400mm × 500mm

Solder Mask Colors: Green, black, blue, red, yellow, purple, and more

Surface Finishes: ENIG, HASL, Immersion Silver, Immersion Tin, ENEPIG, OSP, Bare Copper, and Pure Gold

Where Is CER-XT Used?

CLTE-XT is widely used in high-reliability and high-frequency fields, including:

Advanced Driver Assistance Systems (ADAS)

Microwave Patch Antennas

Phased-Array Radar Systems

High-Power RF Amplifiers

Aerospace and Defense Communications

Why Choose CLTE-XT?

If your design demands low loss, stable performance over temperature, and superior dimensional control, CLTE-XT offers a proven solution. Its blend of electrical and thermal properties makes it a reliable foundation for next-generation RF and microwave systems.

Ready to integrate CLTE-XT into your next project?Contact us today for a quote or technical support!