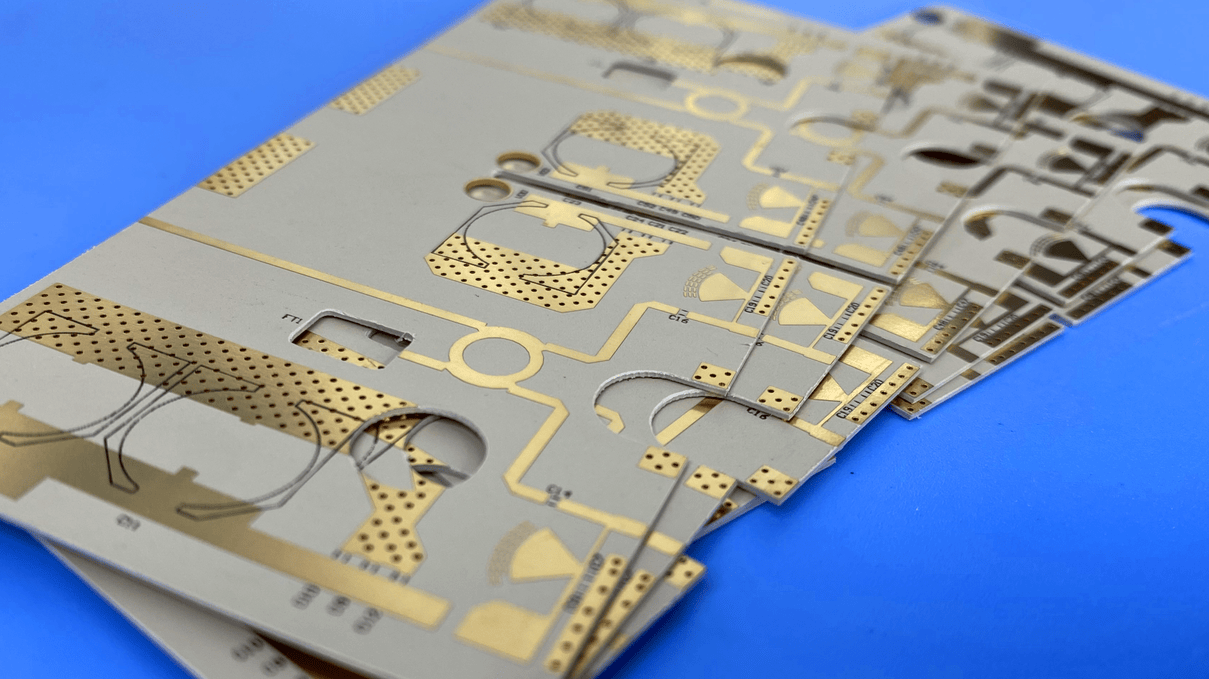

CER-10 High Frequency PCBs for Demanding RF Applications

September 22, 2025

September 22, 2025

In the world of high-frequency electronics, the choice of printed circuit board (PCB) material can make or break your design. That’s why materials like CER-10 — an advanced organic-ceramic laminate from Taconic’s ORCER series — are gaining traction among engineers and designers who refuse to compromise on performance.

Whether you're developing RF components, microwave systems, or high-stability communication devices, CER-10 offers a blend of electrical, mechanical, and thermal properties that set it apart. Let’s dive into what makes this material so special.

What Is CER-10?

CER-10 is a high-frequency laminate built with a woven glass reinforcement and enhanced with Taconic’s proprietary ceramic fill technology. It boasts a dielectric constant of 10 and an impressively low dissipation factor of 0.0035 at 10 GHz, making it ideal for high-speed and high-frequency applications.

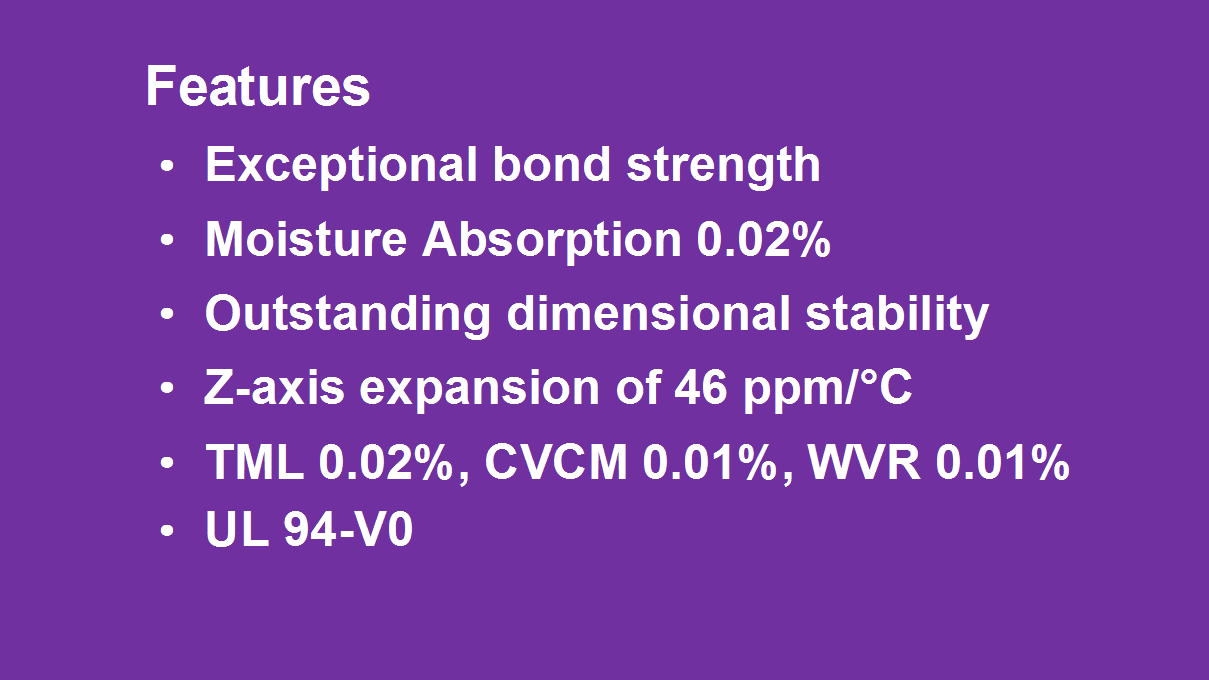

Key Features of CER-10

1.Key Features of CER-10

CER-10 delivers superior interlaminar bond strength and can withstand repeated soldering cycles, ensuring long-term reliability.

2. Ultra-Low Moisture Absorption (0.02%)

Even in humid environments, CER-10 maintains stable electrical performance, reducing the risk of signal degradation.

3.Woven Glass Reinforcement

This provides excellent dimensional stability and enhanced flexural strength, crucial for multilayer and hybrid PCB designs.

4. Optimized Z-Axis CTE (46 ppm/°C)

With a low coefficient of thermal expansion in the Z-axis, CER-10 protects plated through-holes and improves reliability under extreme temperature cycling.

5. Low Outgassing

Ideal for aerospace and vacuum applications, CER-10 meets NASA-outgassing standards with:

Total Mass Loss (TML): 0.02%

Collected Volatile Condensable Materials (CVCM): 0.01%

Water Vapor Regain (WVR): 0.01%

6.UL 94 V-0 Certified

The material meets stringent flame-retardant standards, ensuring safety and compliance.

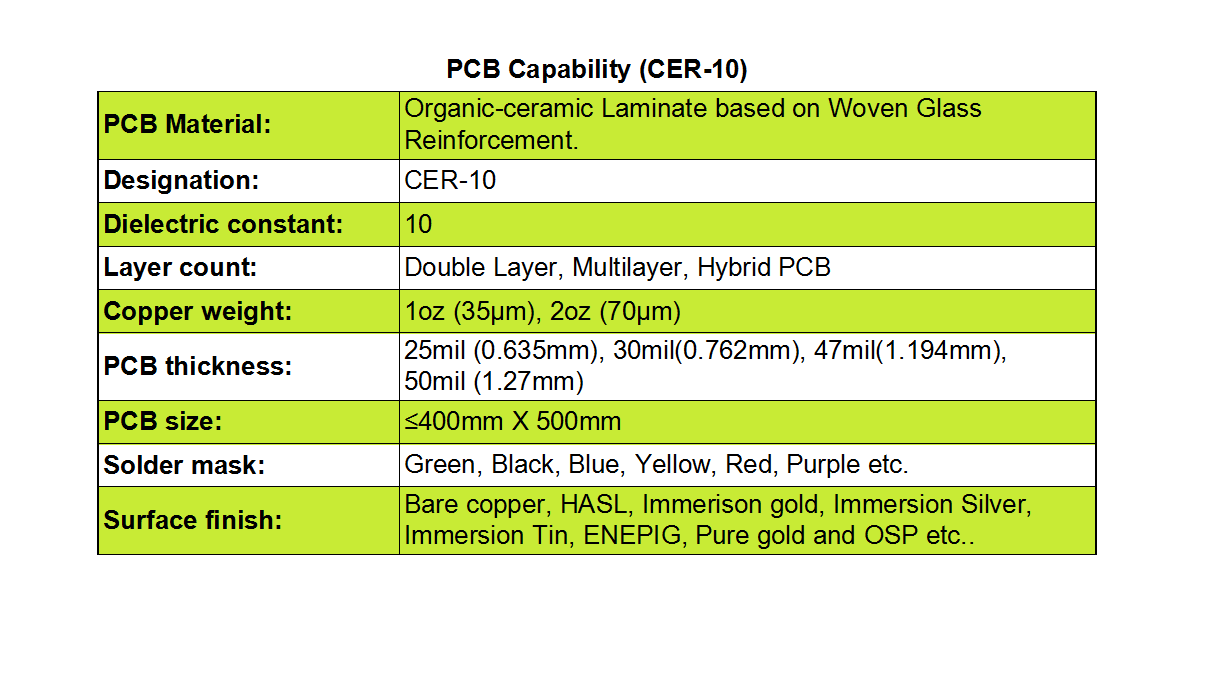

PCB Manufacturing Capabilities

CER-10 PCB Capabilities

Layer Options: Double-layer, multilayer, and hybrid builds

Copper Weights: 1oz (35µm) to 2oz (70µm)

Dielectric Thickness: 25mil (0.635mm) to 50mil (1.27mm)

PCB Size: Up to 400mm x 500mm

Solder Mask Colors: Green, black, blue, yellow, red, purple, and more

Surface Finishes: HASL, ENIG, Immersion Silver, Immersion Tin, ENEPIG, OSP, and others

Where Is CER-10 Used?

CER-10 is the material of choice for high-frequency applications where signal integrity and thermal stability are non-negotiable. Common uses include:

Power Amplifiers

Waveguide Filters

Directional Couplers

Microwave Passive Components

RF Transceivers and Antenna Systems

Conclusion

If you're designing for high-frequency, high-reliability environments, CER-10 offers the electrical consistency, thermal resilience, and mechanical durability you need. It’s more than just a PCB material — it’s a foundation for innovation.

Interested in learning more or ready to start your CER-10 PCB project?Contact us today for a quote or technical support!