High Frequency TMM6 PCB Materials Rogers Circuit Boards Manufacturing

September 14, 2025

September 14, 2025

Introduction

Rogers TMM6 is a high-performance thermoset microwave material engineered for superior plated through-hole reliability in stripline and microstrip applications. This ceramic thermoset polymer composite combines the advantages of traditional PTFE laminates and ceramic materials, without the need for specialized processing. It features a unique dielectric constant (Dk) of 6, distinguishing it within its product family.

Key Features and Benefits of TMM6

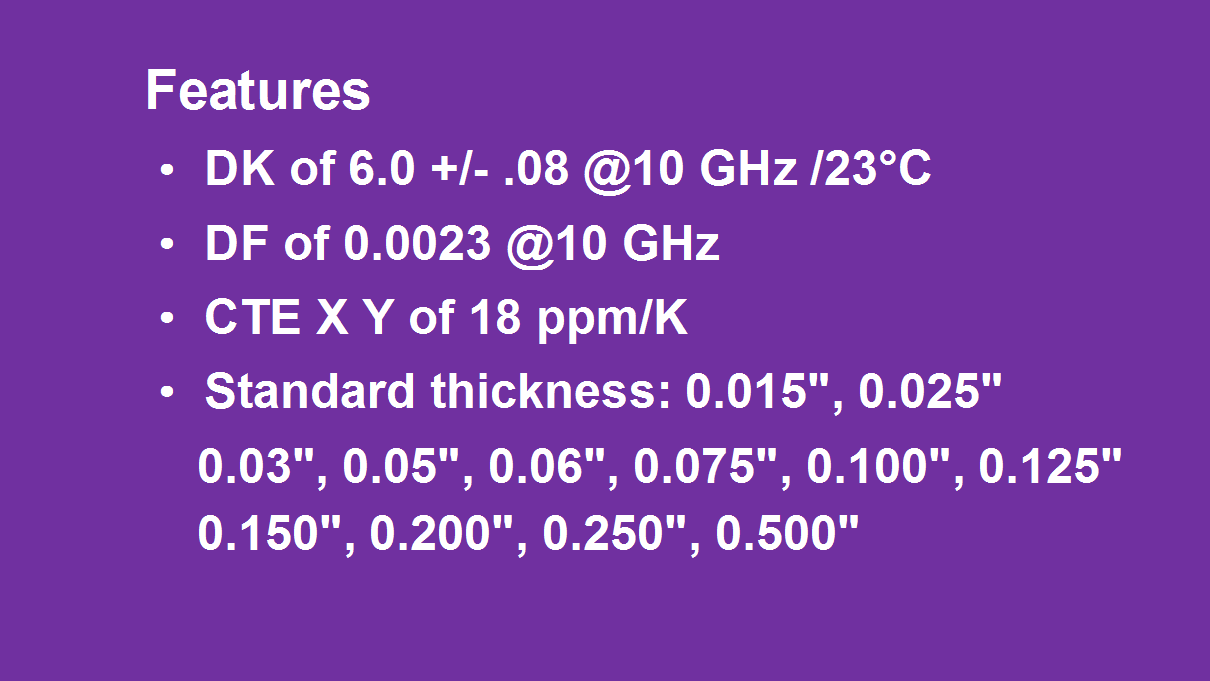

TMM6 delivers exceptional electrical and thermal properties, including a stable dielectric constant (Dk) of 6.0 ± 0.080, a low dissipation factor of 0.0023 at 10 GHz, and a thermal coefficient of Dk of -11 ppm/°K for reliable performance across temperatures.

Its CTE (18 ppm/°K) on X and Y axes is matched to copper, ensuring dimensional stability. Available in thicknesses from 0.0015 to 0.500 inches, TMM6 supports flexible design needs.

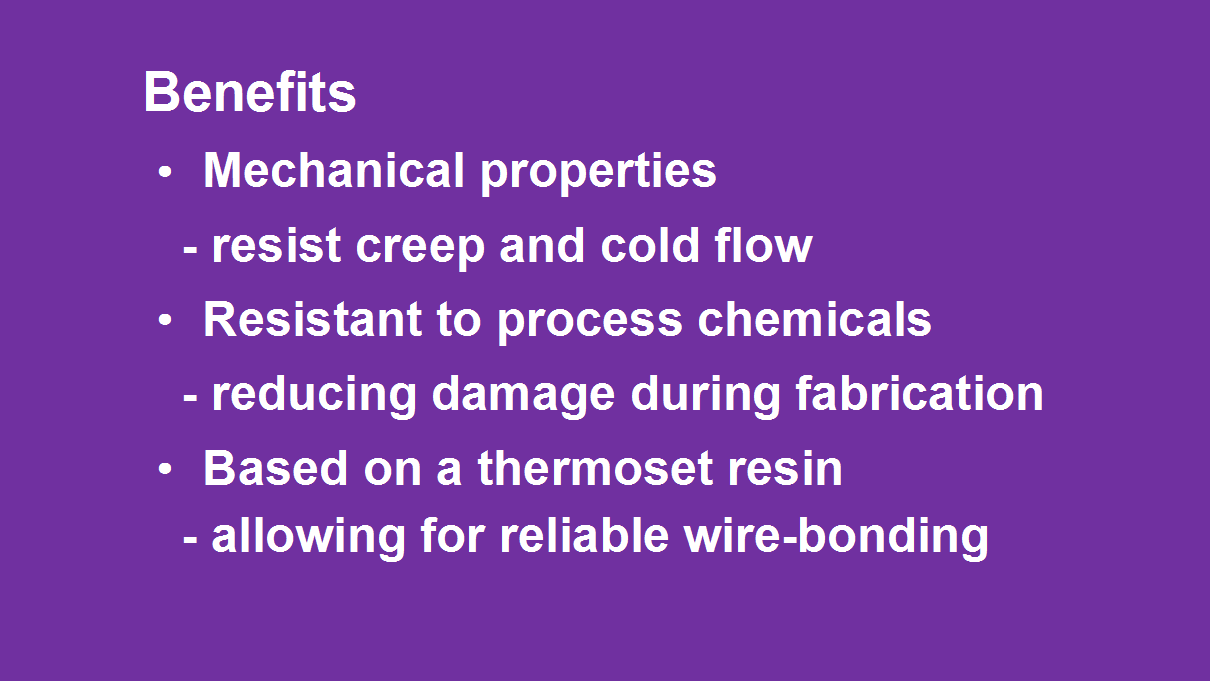

Benefits include excellent resistance to creep, cold flow, and process chemicals, enhancing durability and fabrication yield. The thermoset resin base allows for reliable wire bonding, and its compatibility with standard PCB processes ensures easy integration and broad applicability.

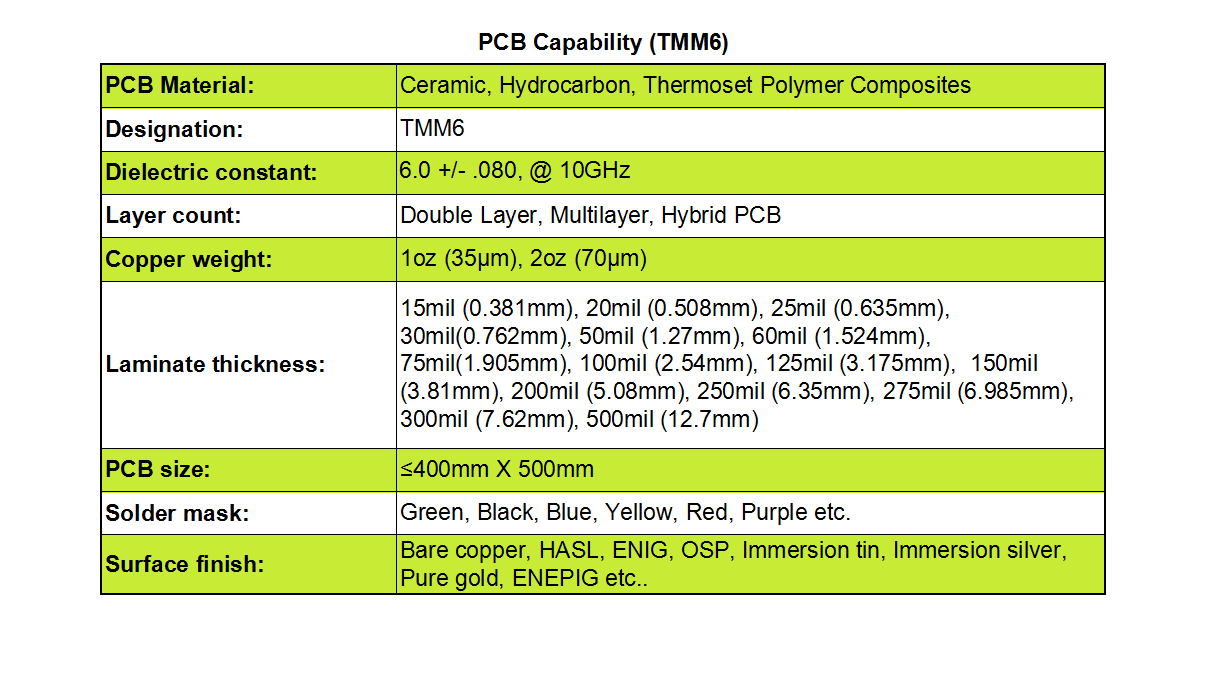

PCB Capabilities with TMM6

We manufacture double-layer, multilayer, and hybrid TMM6 PCBs to meet diverse design requirements.

Copper weights: 1 oz (35 µm) to 2 oz (70 µm)

Board thickness: 15 mil (0.381 mm) to 500 mil (12.7 mm)

Maximum board size: 400 mm x 500 mm

Solder mask colors: Green, Black, Blue, Yellow, Red, Purple

Surface finishes: Bare Copper, HASL, ENIG, OSP, Immersion Tin, Immersion Silver, Pure Gold, ENEPIG

Applications

TMM6 PCBs are ideal for:

Chip testers

Filters and couplers

GPS antennas

Patch antennas

RF circuits