IsoClad 933 Low Loss PCB Material For Stable RF Circuits

September 13, 2025

September 13, 2025

Introduction

Rogers IsoClad 933 laminates are advanced PCB substrates composed of non-woven fiberglass and PTFE. With a higher ratio of non-woven fiberglass to PTFE, this reinforced material delivers exceptional dimensional stability and mechanical strength. Its unique non-woven structure offers flexibility, making it ideal for applications requiring circuit conformability. The use of long random fibers and a proprietary manufacturing process ensures outstanding stability and durability, distinguishing it from traditional woven fiberglass laminates.

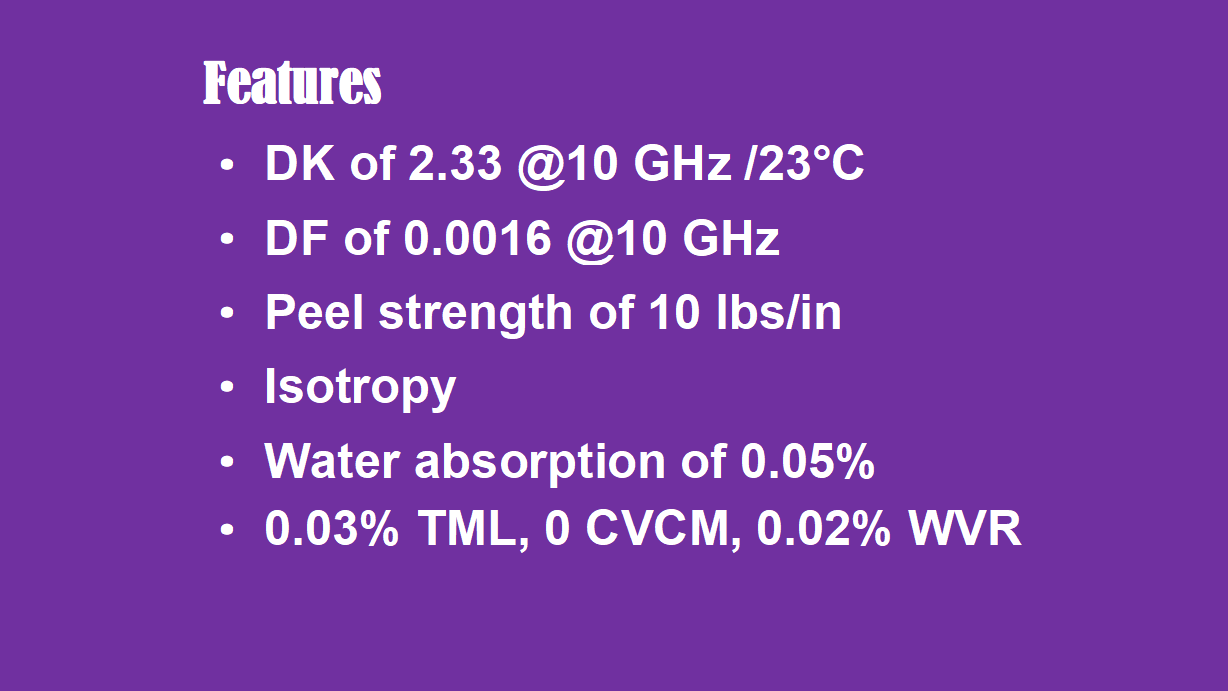

Key Features

Low dielectric constant (Dk) of 2.33 @ 10 GHz and 23°C for minimal signal loss

Ultra-low dissipation factor of 0.0016 for reduced energy loss in high-frequency circuits

High peel strength of 10 lbs per inch for robust mechanical adhesion

Excellent isotropic behavior across X, Y, and Z axes

Low water absorption (0.05%) and minimal outgassing (0.03% TML, 0 CVCM, 0.02% WVR)

Superior Dk uniformity for consistent performance

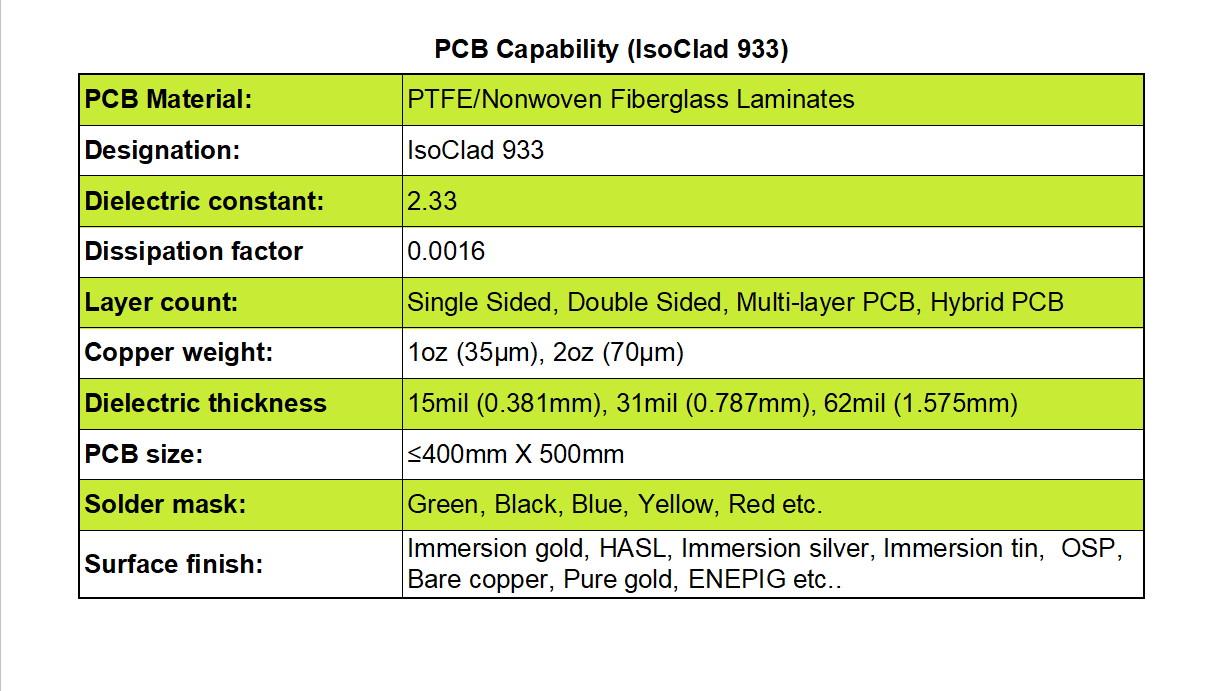

PCB Manufacturing Capabilities

IsoClad 933 supports double-sided, multilayer, and hybrid PCB configurations. Available copper weights include 1oz (35µm) and 2oz (70µm). Dielectric thickness options include 15 mils (0.381mm), 31 mils (0.787mm), and 62 mils (1.575mm). Maximum board dimensions reach 400mm x 500mm. Solder mask colors: green, black, blue, yellow, red. Surface finishes: immersion gold, HASL, immersion silver, immersion tin, OSP, bare copper, pure gold, ENEPIG.

Applications

Conformal antennas, stripline and microstrip circuits, advanced guidance systems, radar systems, and electronic warfare systems benefit from the low-loss and high-performance characteristics of IsoClad 933 PCBs.

Thank you for reading. We look forward to sharing more insights with you soon.