RO4350B High-Frequency PCB - Superior RF Performance with FR-4 Processing

July 10, 2025

July 10, 2025

1.Introduction to RO4350B Material

Rogers RO4350B laminates combine woven glass reinforced hydrocarbon/ceramics to deliver PTFE-like RF performance with FR-4 manufacturability. These UL 94 V-0 rated materials eliminate specialized PTFE processing while providing:

Dielectric Constant (Dk): 3.48 @10GHz (±0.05 control)

Dissipation Factor (Df): 0.0037 @10GHz

High Tg: 280°C+ for thermal reliability

Z-axis CTE: 32 ppm/°C (matched to copper)

2.Key Advantages Over Traditional RF Materials

Cost Savings - Uses standard FR-4 processing (no PTFE handling)

Thermal Stability - Withstands lead-free reflow (280°C Tg)

Hybrid Design Ready - Compatible with FR-4 in multilayer stacks

High-Power Capable - UL 94 V-0 flame rating

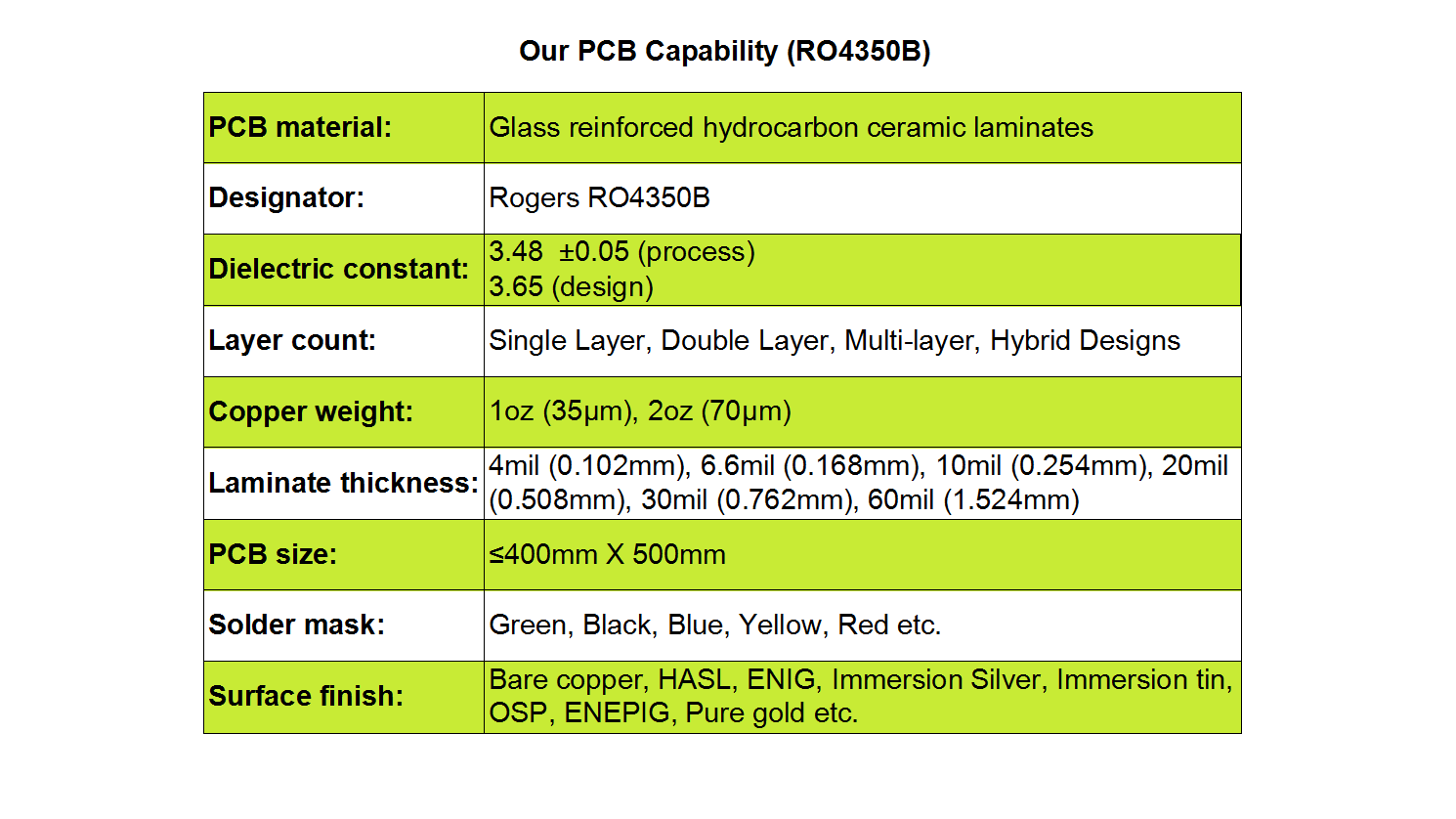

3.RO4350B PCB Manufacturing Capabilities

Layer Stack-Up Options

Single/Double-sided, 2-32 multilayer, Hybrid constructions

Thickness Range: 4mil to 60mil (including 4, 6.6, 10, 13.3, 16.6, 20, 30, 60mil)

Materials & Finishes

Copper Weights: 1oz & 2oz (rolled/ED copper)

Surface Finishes: ENIG, ENEPIG, Immersion Silver/Tin, HASL, OSP, Pure Gold

Solder Mask Colors: Green, Black, Red, Yellow, Blue

Production Capabilities

Max Panel Size: 400mm × 500mm

Impedance Control: ±5% tolerance

Min Trace/Space: 3/3mil (75/75μm)

4. Applications of RO4350B PCBs

5G Infrastructure: Massive MIMO, mmWave antennas

Base Station Components: Power amplifiers, filters

Aerospace & Defense: Radar systems, EW equipment

Automotive Radar: 24/77GHz ADAS sensors

Medical RF Devices: MRI, therapeutic equipment

5.Why Choose Our RO4350B PCBs?

FR-4 Process Compatibility - Faster turnaround than PTFE

High-Tg Reliability - Survives multiple reflow cycles

Precision RF Performance - Tight Dk control for mmWave

Hybrid Construction - Mix with FR-4 for cost optimization

Request a Quote Today for RO4350B PCBs tailored to your layer count (2-32L) and thickness (4-60mil) requirements.