TC350 High-Frequency PCB - Superior Thermal Management for RF Power Applications

July 11, 2025

July 11, 2025

1.Introduction to TC350 Material

Rogers TC350 high frequency PCBs combine PTFE, thermally conductive ceramic fillers, and woven glass reinforcement to deliver superior thermal management and electrical performance. These laminates effectively reduce hot spots, improve heat dissipation, and enhance reliability in high-power RF applications.

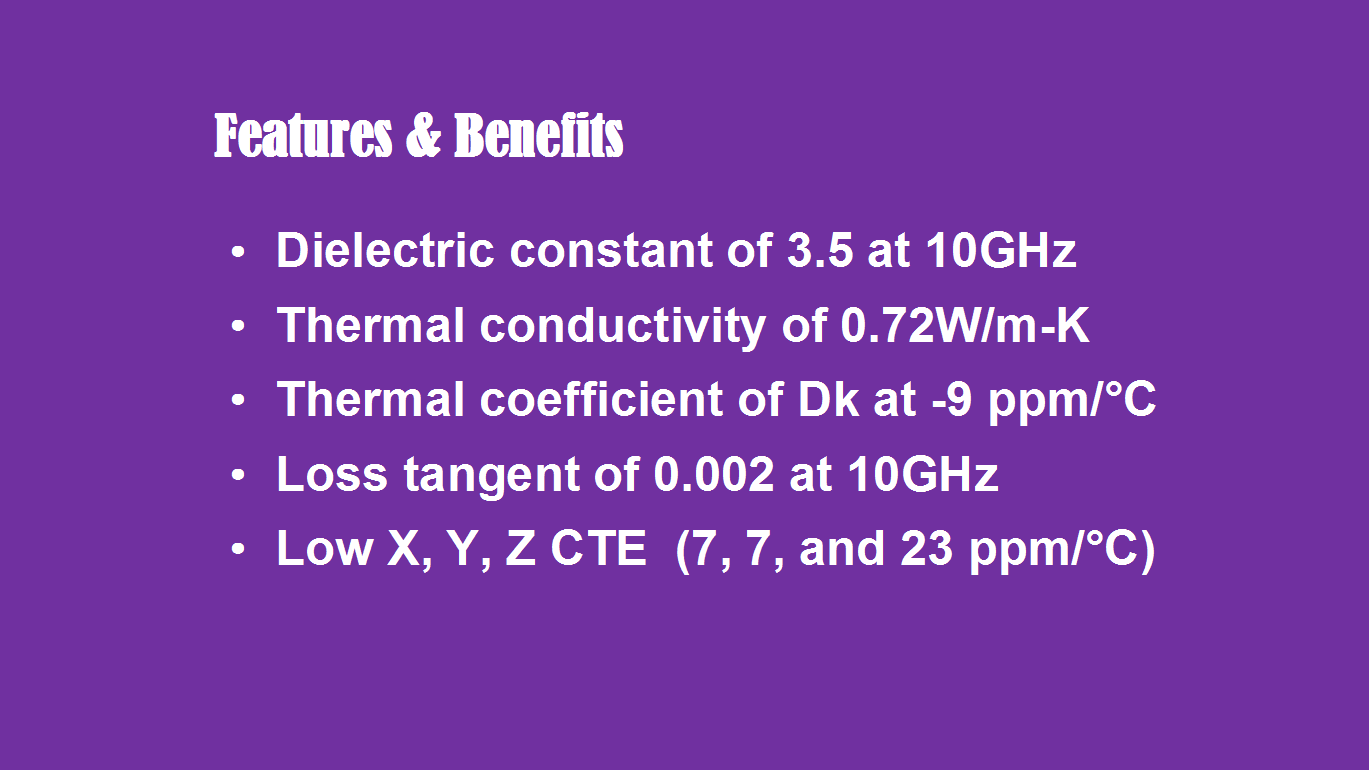

2.Key Features and Benefits (H2)

Optimized Thermal Conductivity: 0.72W/m-K for effective heat dissipation

Stable Dielectric Properties: Dk of 3.5 with low thermal coefficient (-9 ppm/°C)

Minimal Signal Loss: 0.002 loss tangent at 10GHz for improved efficiency

Excellent Dimensional Stability: Low CTE (X/Y:7ppm/°C, Z:23ppm/°C)

Enhanced Reliability: Reduces solder fatigue and extends component lifespan

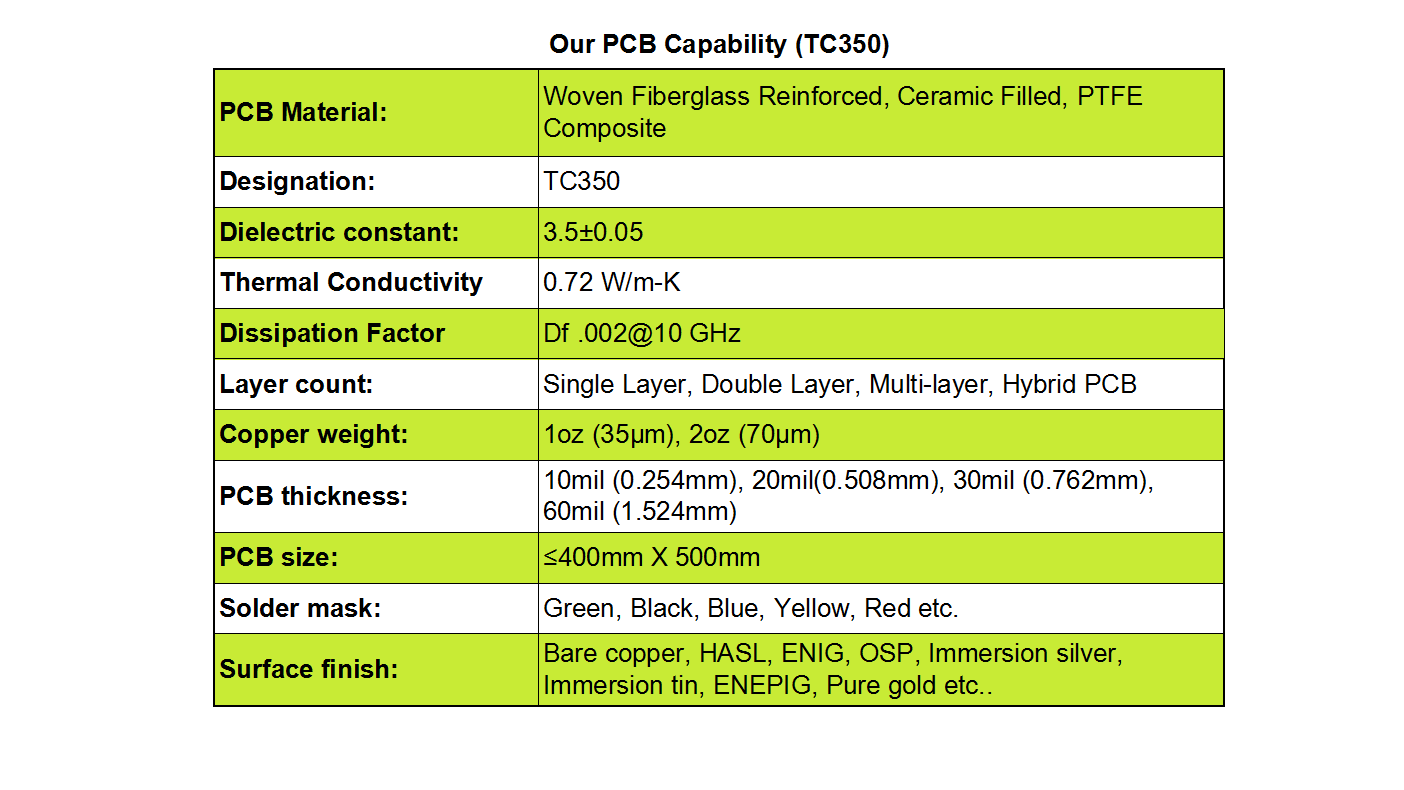

3.PCB Capabilities

Board Types: Single/double-sided, multilayer, and hybrid configurations

Copper Options: 1oz (35µm) and 2oz (70µm) available

Thickness Range: 10mil to 125mil (0.254mm-3.175mm)

Panel Size: Up to 400mm × 500mm

Customization: Multiple solder mask colors and surface finishes (ENIG, HASL, immersion silver, etc.)

4. Applications

Power amplifiers and filters

RF couplers and combiners

Tower-mounted amplifiers (TMA/TMB)

Microwave power dividers

High-frequency communication systems

5.Call to Action

Maximize your RF system performance with TC350's thermal advantages - contact us for your high-power PCB solutions.