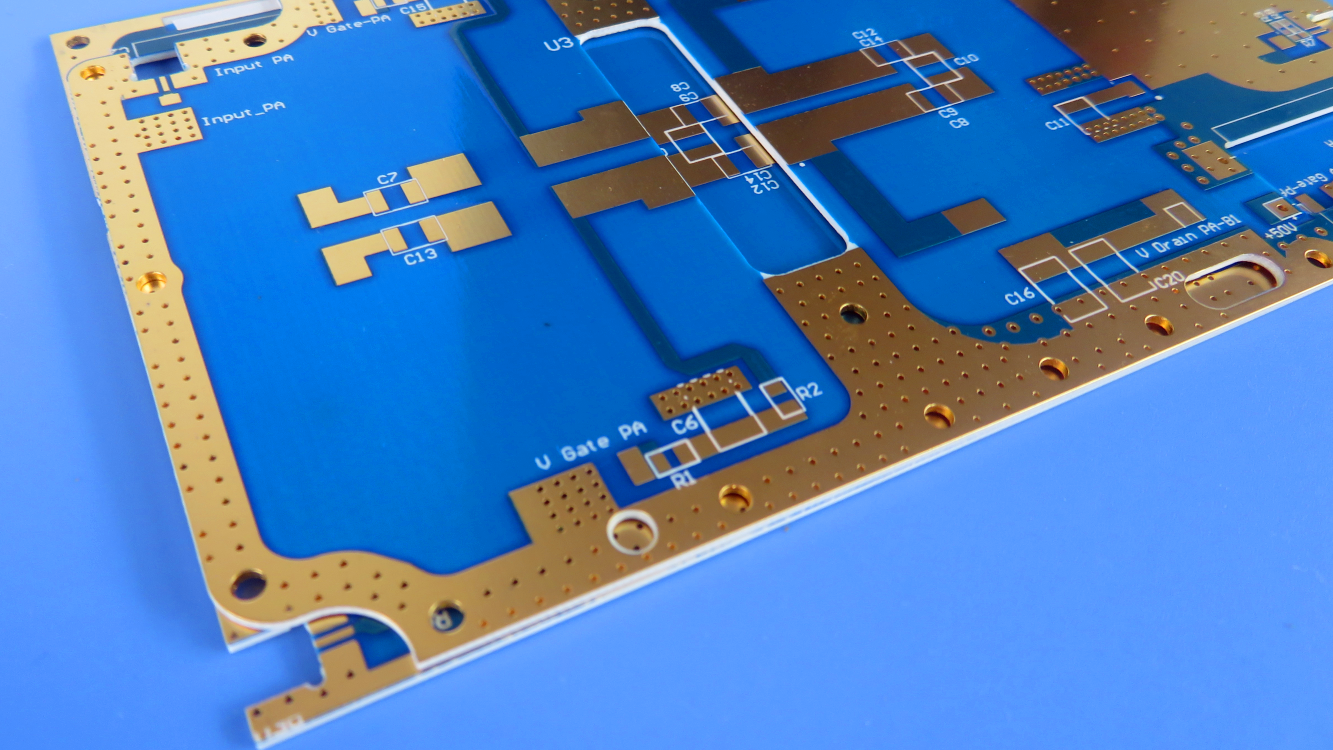

Rogers Kappa 438 High Frequency PCB Fabrication for Advanced Wireless and IoT Applications

August 24, 2025

August 24, 2025

Introduction

Rogers RO3010 represents a premium series of ceramic-filled PTFE composite materials engineered to deliver high dielectric constant with exceptional stability. These cost-effective laminates provide outstanding mechanical and electrical reliability, making them ideal for broadband component design and circuit miniaturization across diverse frequency applications.

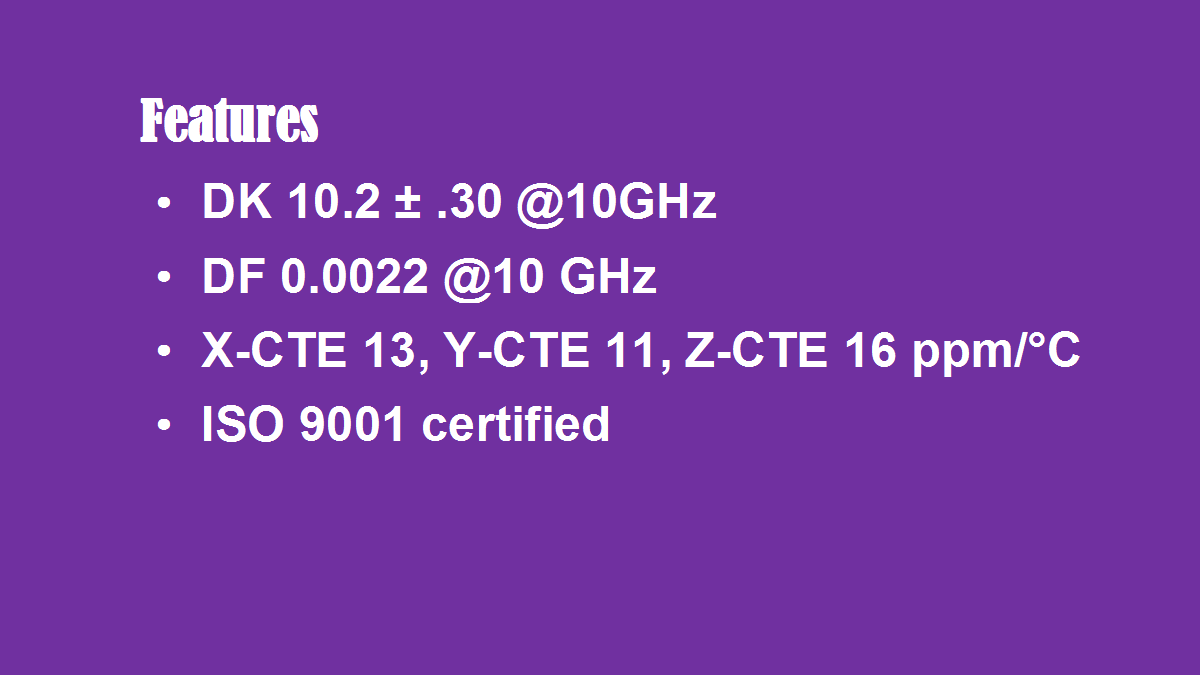

Key Material Properties

High dielectric constant of 10.2±0.30 at 10 GHz ensures superior signal handling

Ultra-low dissipation factor of 0.0022 at 10 GHz minimizes signal loss

Low CTE values (X:13 ppm/°C, Y:11 ppm/°C, Z:16 ppm/°C) ensure exceptional dimensional stability

CTE closely matched to copper reduces phase shift under temperature variations

ISO 9001 certification guarantees consistent quality and reliability

Excellent suitability for complex multi-layer board designs

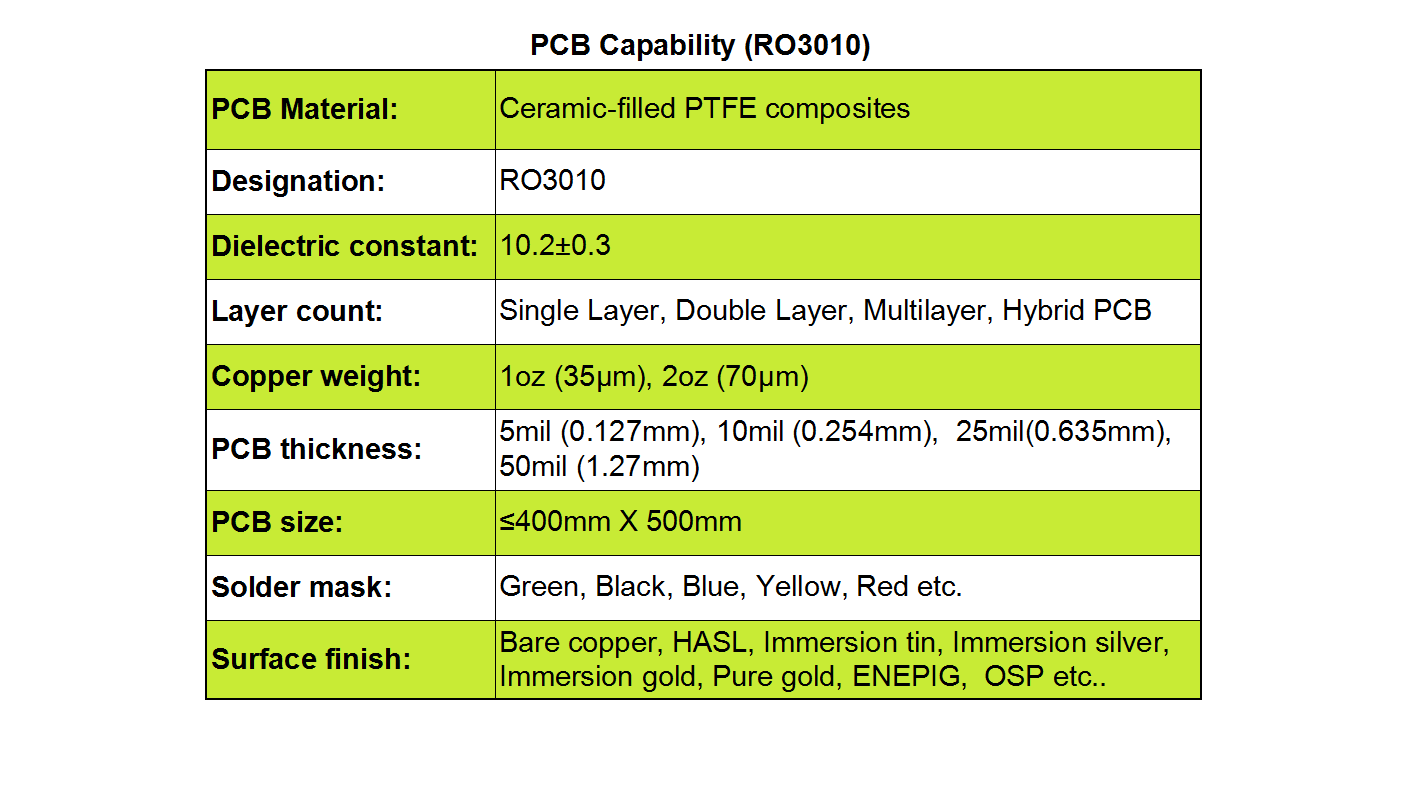

PCB Manufacturing Capabilities

Our RO3010 PCB fabrication services include

Single-layer, double-layer, multilayer and hybrid constructions

Copper weight options of 1 oz (35 μm) and 2 oz (70 μm)

Thickness selections: 5 mil (0.127 mm), 10 mil (0.254 mm), 25 mil (0.635 mm), 50 mil (1.27 mm)

Maximum board dimensions of 400 × 500 mm

Multiple solder mask colors including green, black, blue, yellow and red

Comprehensive surface finishes including ENIG, HASL, immersion silver, immersion tin, ENEPIG, OSP and pure gold

Applications

RO3010 circuit boards excel in high-frequency applications including

Automotive radar and collision avoidance systems

Global positioning satellite (GPS) antennas

Cellular telecommunications infrastructure

Patch antennas for wireless communications

Direct broadcast satellite systems

RF identification (RFID) systems

Microwave point-to-point connections

Utilize our manufacturing expertise for your high-frequency PCB requirements with Rogers RO3010 materials designed for superior performance in demanding RF and microwave applications.