Rogers TMM10 High Frequency PCB - Complete Technical Guide

August 9,2025

August 9,2025

Introduction

Rogers TMM10 is a premium ceramic-thermoset composite material engineered for high-reliability stripline and microstrip applications. Combining the benefits of PTFE and ceramic substrates without their limitations, TMM10 delivers exceptional electrical and mechanical performance for demanding RF designs.

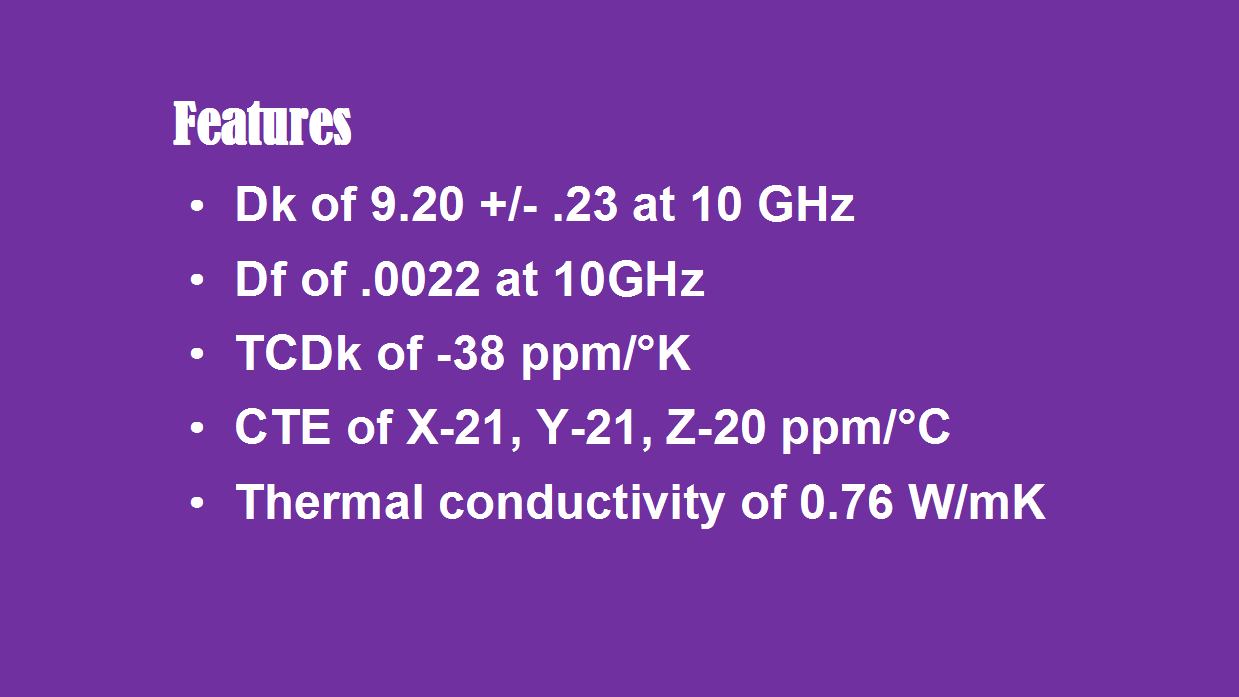

Key Features

High Dielectric Constant (Dk): 9.20 ± 0.23 (enables circuit miniaturization)

Ultra-Low Loss: Dissipation factor of 0.0022 @ 10GHz

Temperature Stability: -38 ppm/°K thermal coefficient of Dk

Matched CTE: 21 ppm/°K (X/Y), 20 ppm/°K (Z) for reliable PTH connections

Enhanced Thermal Conductivity: 0.76 W/mK (2× better than standard PTFE)

Mechanical Durability: Excellent resistance to creep and cold flow

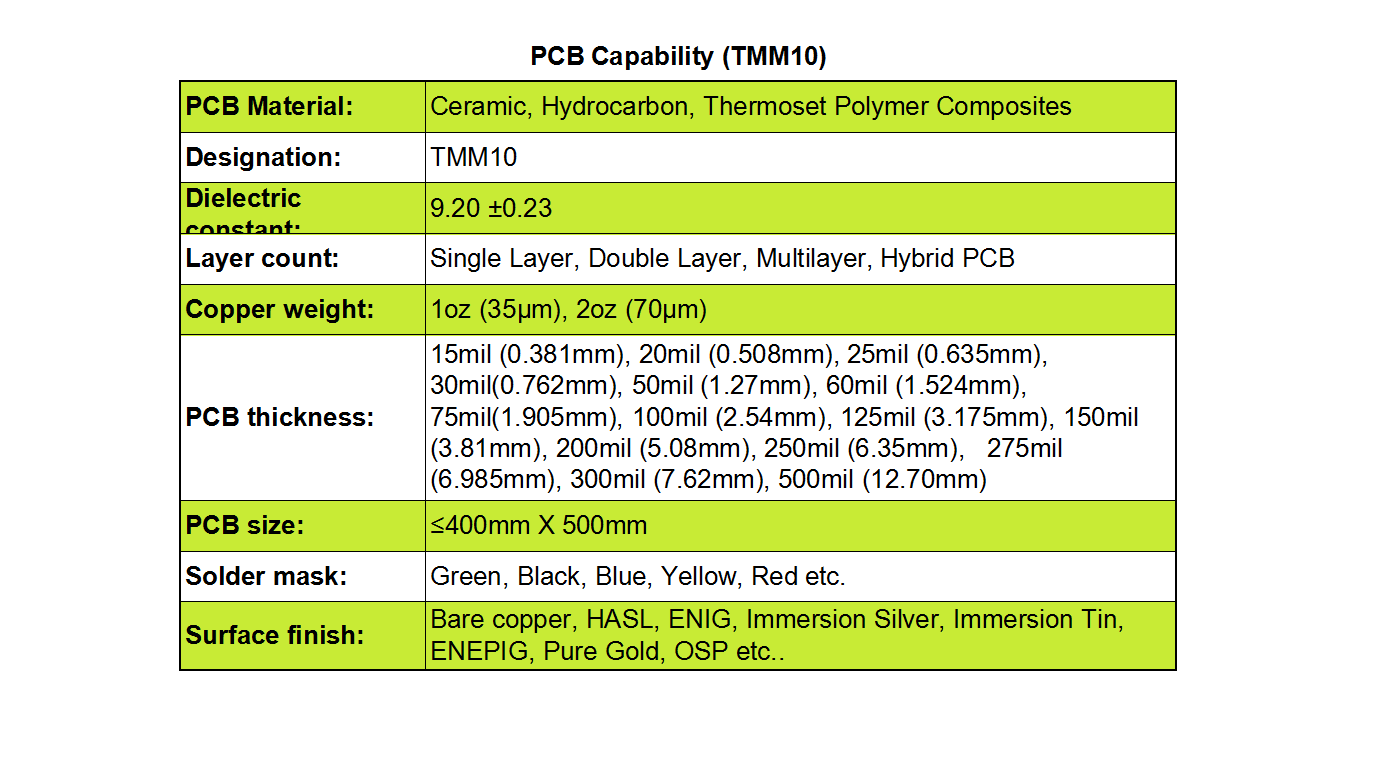

PCB Manufacturing Capabilities

Layer Options: Single, double, multi-layer & hybrid configurations

Copper Weights: 1oz (35µm) & 2oz (70µm)

Thickness Range: 15mil (0.38mm) to 500mil (12.7mm)

Max Board Size: 400mm × 500mm

Surface Finishes: ENIG, HASL, Immersion Silver/Tin, ENEPIG, OSP, Pure Gold

Solder Mask Colors: Green, black, blue, yellow, red

Applications

Satellite communication systems

GPS and patch antennas

Dielectric polarizers

High-frequency chip testers

Military/aerospace RF components