RO3210 High-Frequency PCB: Features, Benefits & Applications for RF and Automotive Systems

August 8,2025

August 8,2025

Introduction

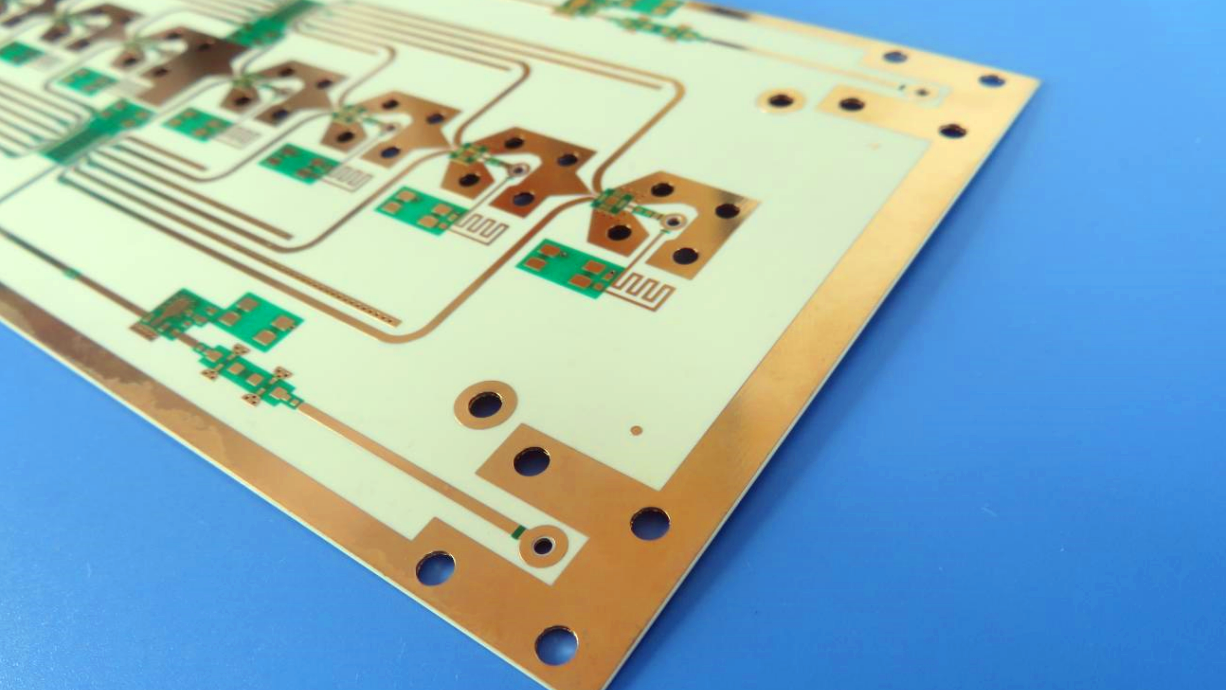

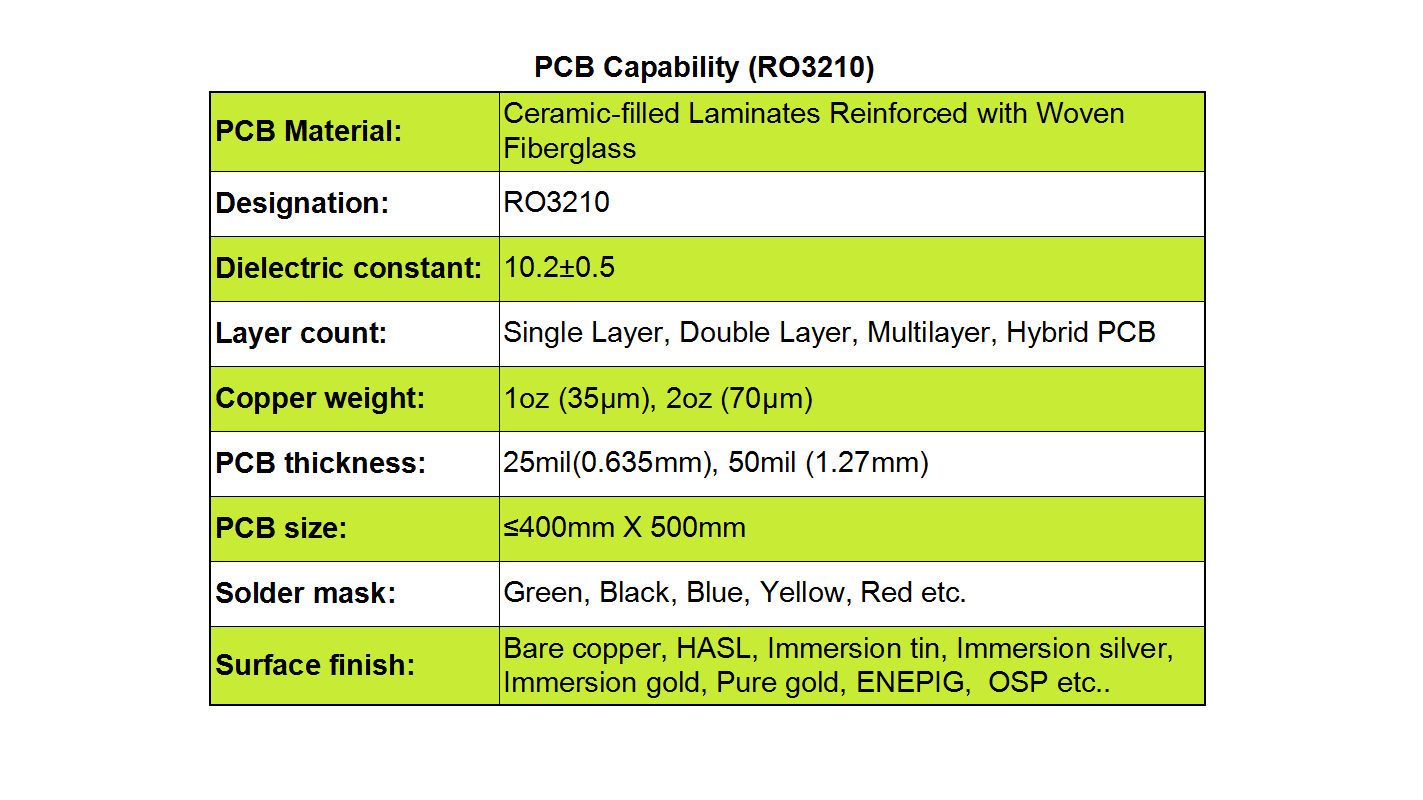

Rogers RO3210 is a ceramic-filled, woven fiberglass laminate designed for high-frequency applications, offering exceptional electrical efficiency and mechanical strength at competitive prices. As part of the RO3000 series, RO3210 excels in mechanical stability, making it a top choice for demanding industries.

Key Features & Benefits

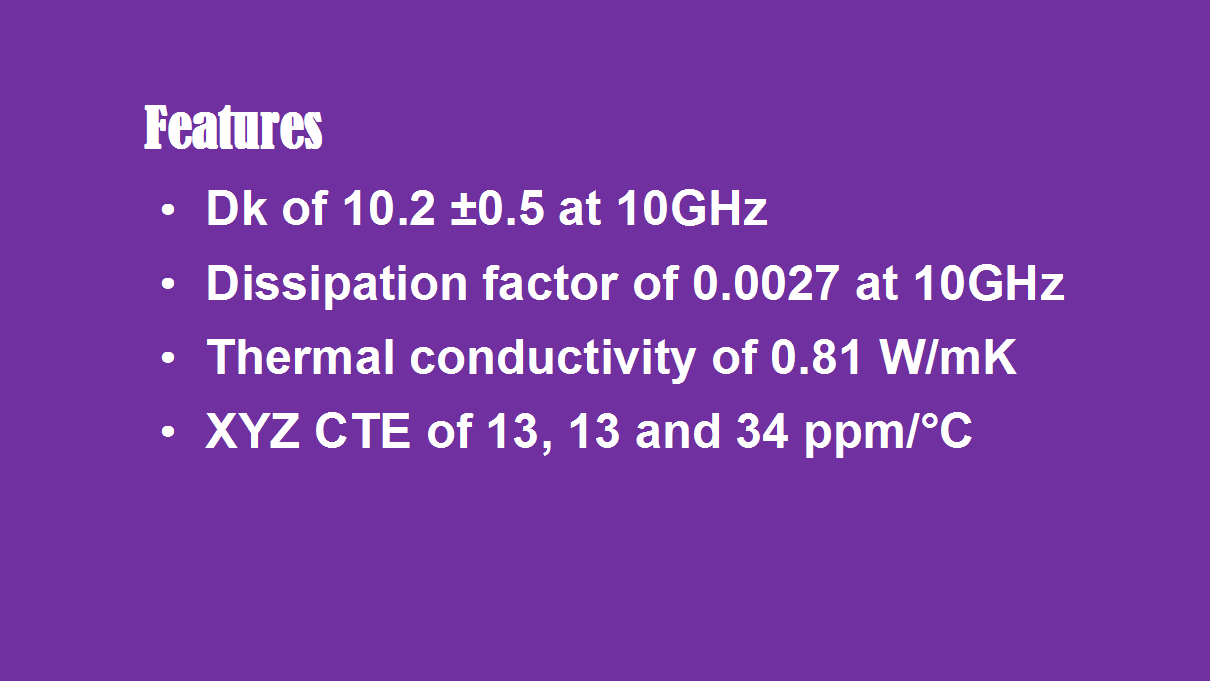

High Dielectric Constant (Dk): 10.2 (±0.5) enables compact and miniaturized designs.

Low Signal Loss: Dissipation factor of 0.0027 at 10 GHz ensures minimal distortion.

Thermal Performance: High thermal conductivity (0.81 W/mK) and excellent CTE values enhance reliability.

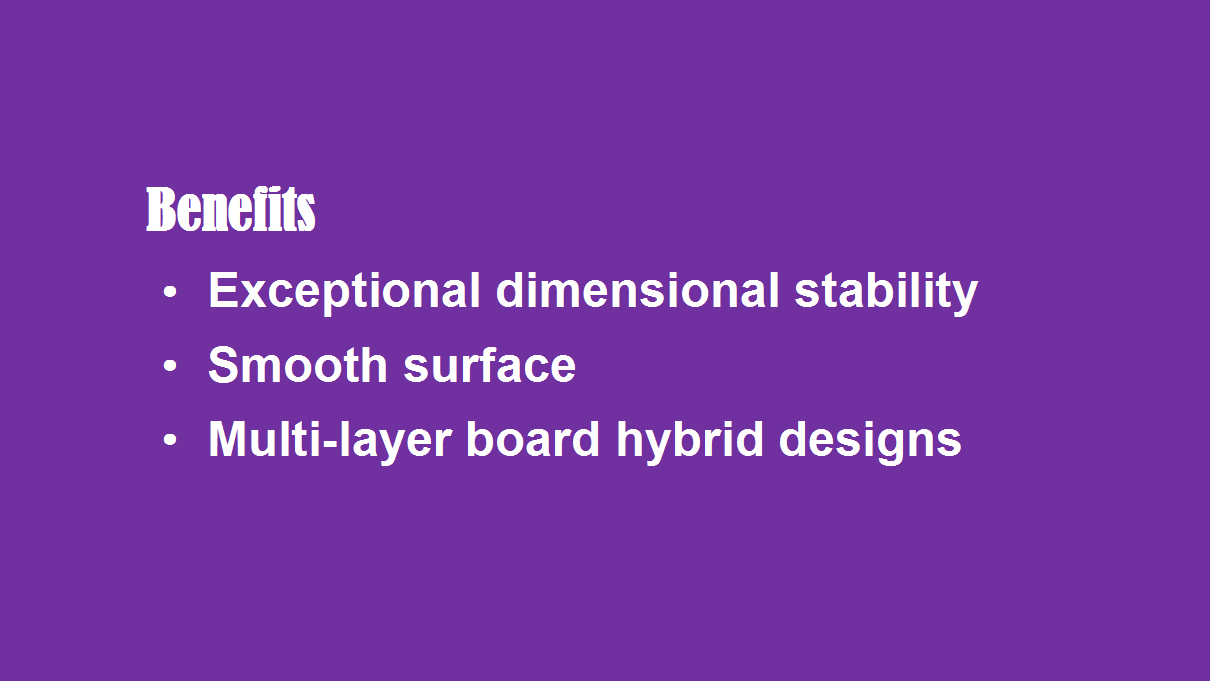

Dimensional Stability: Ensures precision and boosts production yields.

Surface Smoothness: Supports finer line etching for intricate circuit designs.

Hybrid Compatibility: Integrates seamlessly into epoxy multi-layer boards for versatile configurations.

PCB Manufacturing Capabilities

Layer Options: Single-layer to complex multi-layer and hybrid designs.

Copper Weights: 1oz (35µm) and 2oz (70µm) for tailored conductivity.

Thickness Options: 25 mils (0.635mm) and 50 mils (1.27mm).

Max Size: Up to 400mm x 500mm.

Customization: Solder mask colors (green, black, blue, etc.) and finishes (HASL, ENIG, OSP, etc.).

Applications

Ideal for:

Automotive: Collision avoidance systems, GPS antennas.

Wireless Communications: Telecommunications systems, microstrip patch antennas.

Satellite Technology: Direct broadcast satellites and other high-frequency RF applications.