TC600 High-Frequency PCB – Features, Capabilities & Applications

August 12,2025

August 12,2025

Introduction

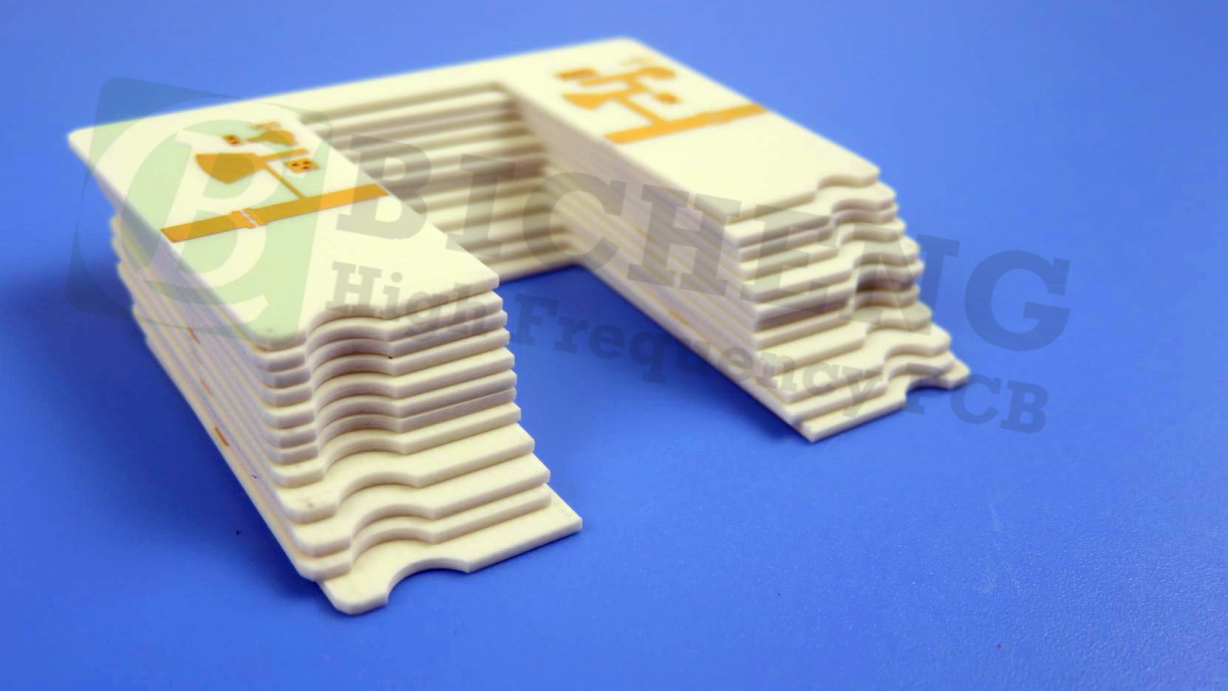

Rogers TC600 is a advanced PTFE-based composite material reinforced with woven fiberglass and ceramic fillers. Engineered specifically for high-performance printed circuit boards, it delivers best-in-class thermal conductivity, reduced dielectric loss, and minimal insertion loss. These properties make it an ideal substrate for amplifiers, antennas, and other RF applications where efficiency and thermal management are critical.

The exceptional heat dissipation capability supports higher power handling, reduces hot spots, and enhances overall device reliability. TC600 works seamlessly with thermal management techniques such as heat sinks, coins, and thermal vias, giving designers greater flexibility and margin in thermal design.

Key Features

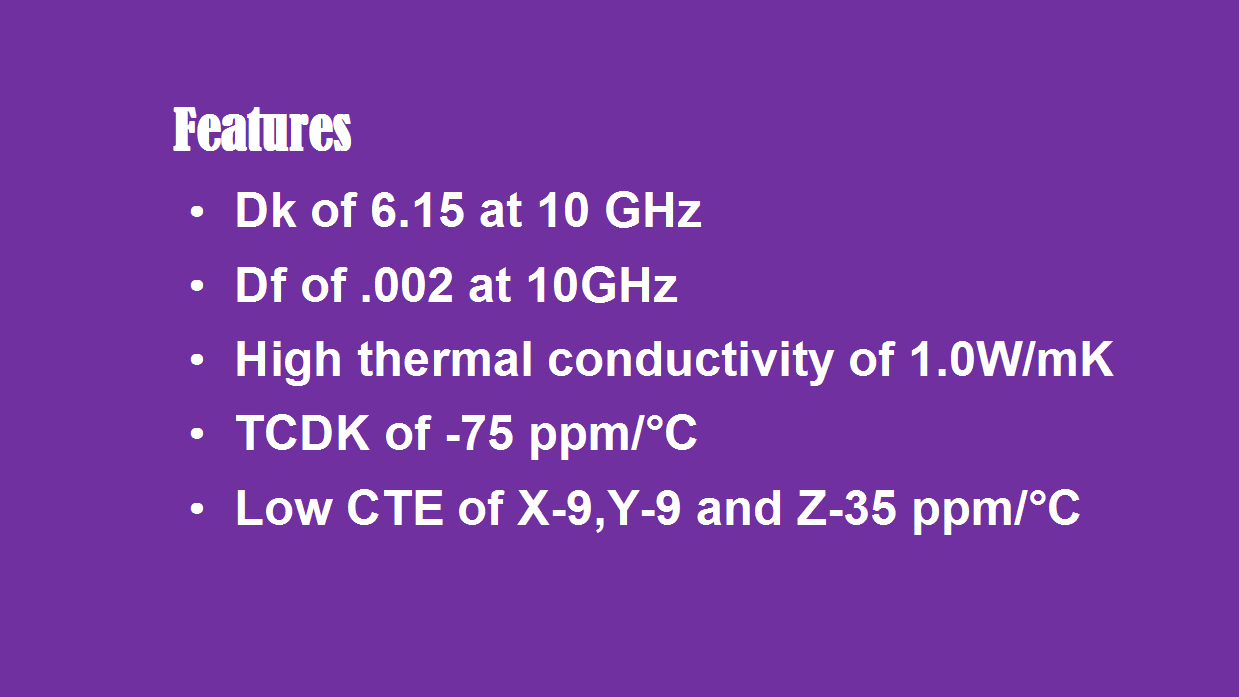

High Dielectric Constant (DK): 6.15 for compact circuit design

Low Dissipation Factor: 0.002 at 10 GHz for minimal signal loss

Excellent Thermal Conductivity:

Z-axis: 1.1 W/mK

X/Y-axis: 1.4 W/mK

Stable Dielectric Constant: TCDk of -75 ppm/°C from -40°C to 150°C at 10 GHz

Low Z-CTE: 35 ppm/°C for reliable plated through holes

These features ensure stable performance across temperature variations, making TC600 ideal for power amplifiers and antennas where gain and bandwidth consistency are crucial.

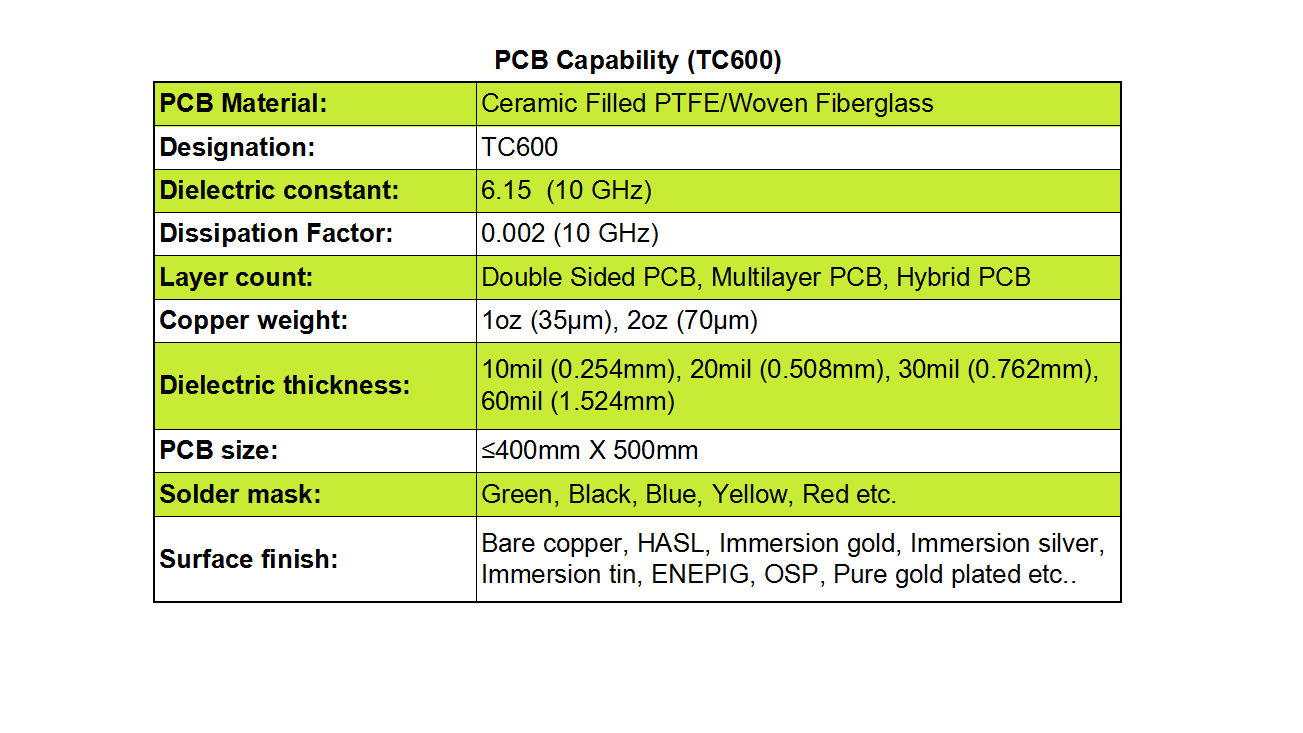

TC600 PCB Manufacturing Capabilities

We support a wide range of PCB configurations and customizations to meet diverse design requirements:

Layers: Double-sided, multilayer, and hybrid PCBs

Copper Weight: 1oz (35µm) or 2oz (70µm)

Dielectric Thickness: 10mil, 20mil, 30mil, 60mil (0.254mm – 1.524mm)

Max PCB Size: 400mm x 500mm

Solder Mask Colors: Green, Black, Blue, Yellow, Red, and more

Surface Finishes: HASL, ENIG, Immersion Silver, Immersion Tin, ENEPIG, OSP, Pure Gold Plating

Our advanced manufacturing ensures high signal integrity, thermal performance, and reliability for your high-frequency applications.

Applications

TC600 is widely used in high-frequency and RF applications, including:

Power amplifiers, filters, and couplers

Microwave combiners and power dividers in avionics

Compact and small-sized antennas

DAB (Digital Audio Broadcasting) and satellite radio antennas

GPS antennas and handheld RFID readers

TC600 from Rogers offers unmatched thermal performance, signal integrity, and design flexibility for high-frequency PCBs. Whether you're designing power amplifiers, RF systems, or compact antennas, TC600 provides the reliability and performance needed in demanding environments.