TMM13i High Dk Ceramic Thermoset RF PCB Manufacturing Capabilities and Services

August 16, 2025

August 16, 2025

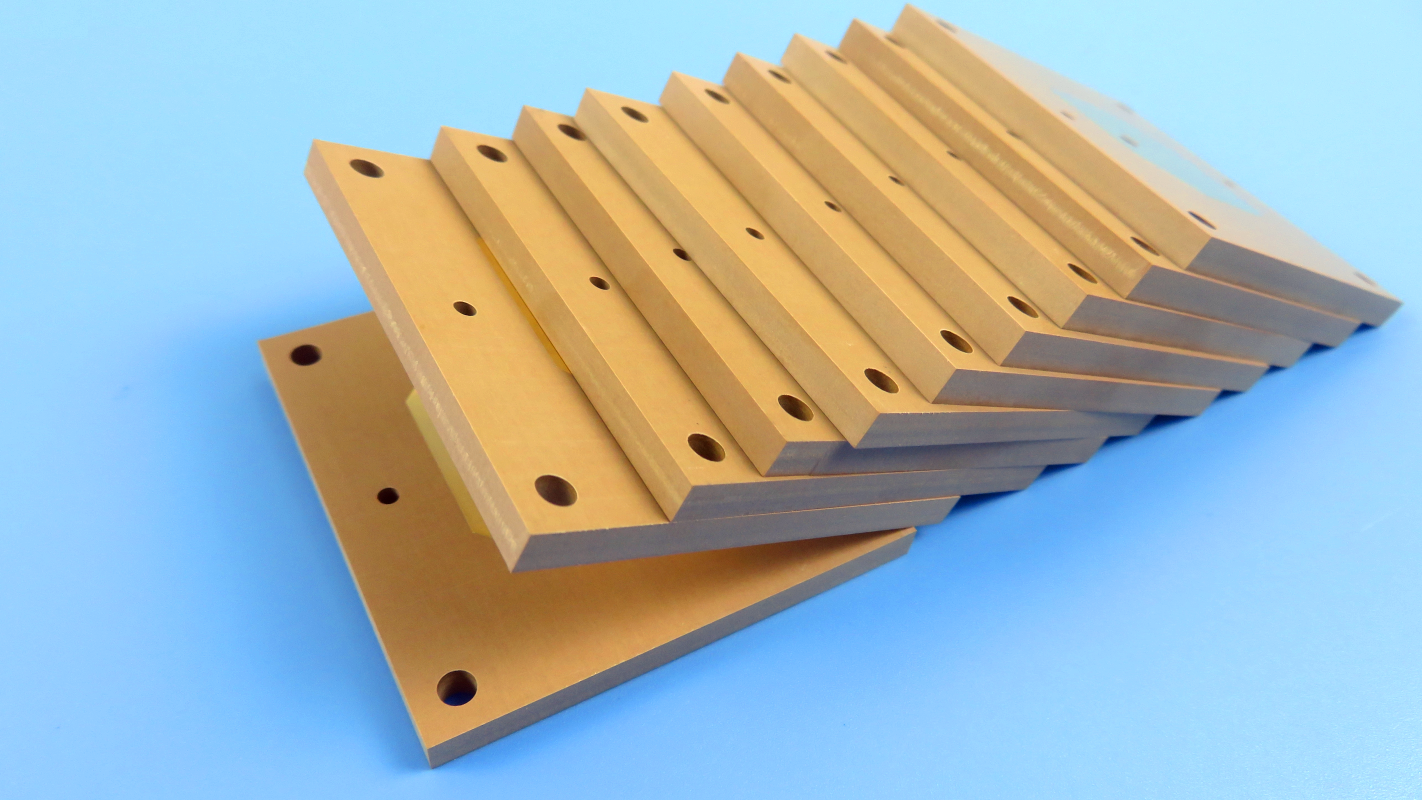

Introduction to Rogers TMM13i High Frequency PCBs

Rogers TMM13i is an isotropic thermoset microwave material engineered for high-reliability plated through-hole strip-line and micro-strip applications. This ceramic thermoset polymer composite combines the benefits of ceramic and PTFE substrates while supporting soft substrate processing techniques.

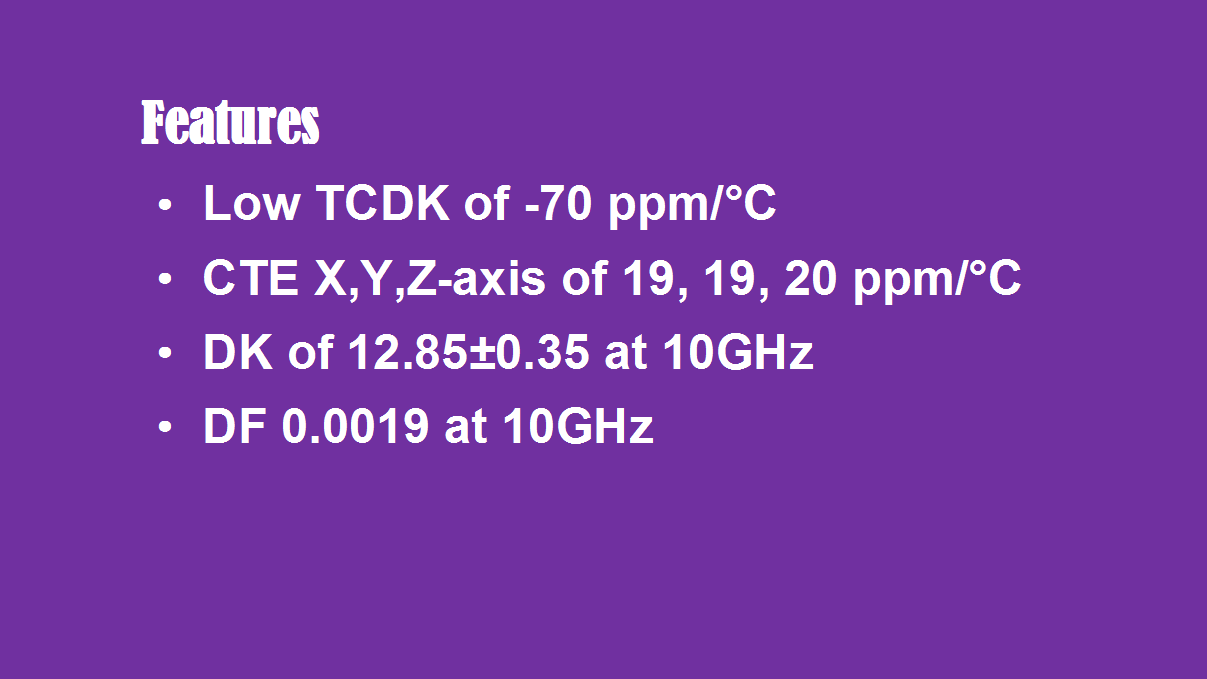

Key Features of TMM13i Laminates

Low thermal coefficient of dielectric constant: –70 ppm/°C for stable performance across temperatures

Isotropic CTE (19/19/20 ppm/°C in X/Y/Z) closely matched to copper for reliable PTH and minimal etch shrinkage

High dielectric constant: 12.85±0.35 enabling component miniaturization

Low dissipation factor: 0.0019 @ 10 GHz for reduced energy loss in microwave circuits

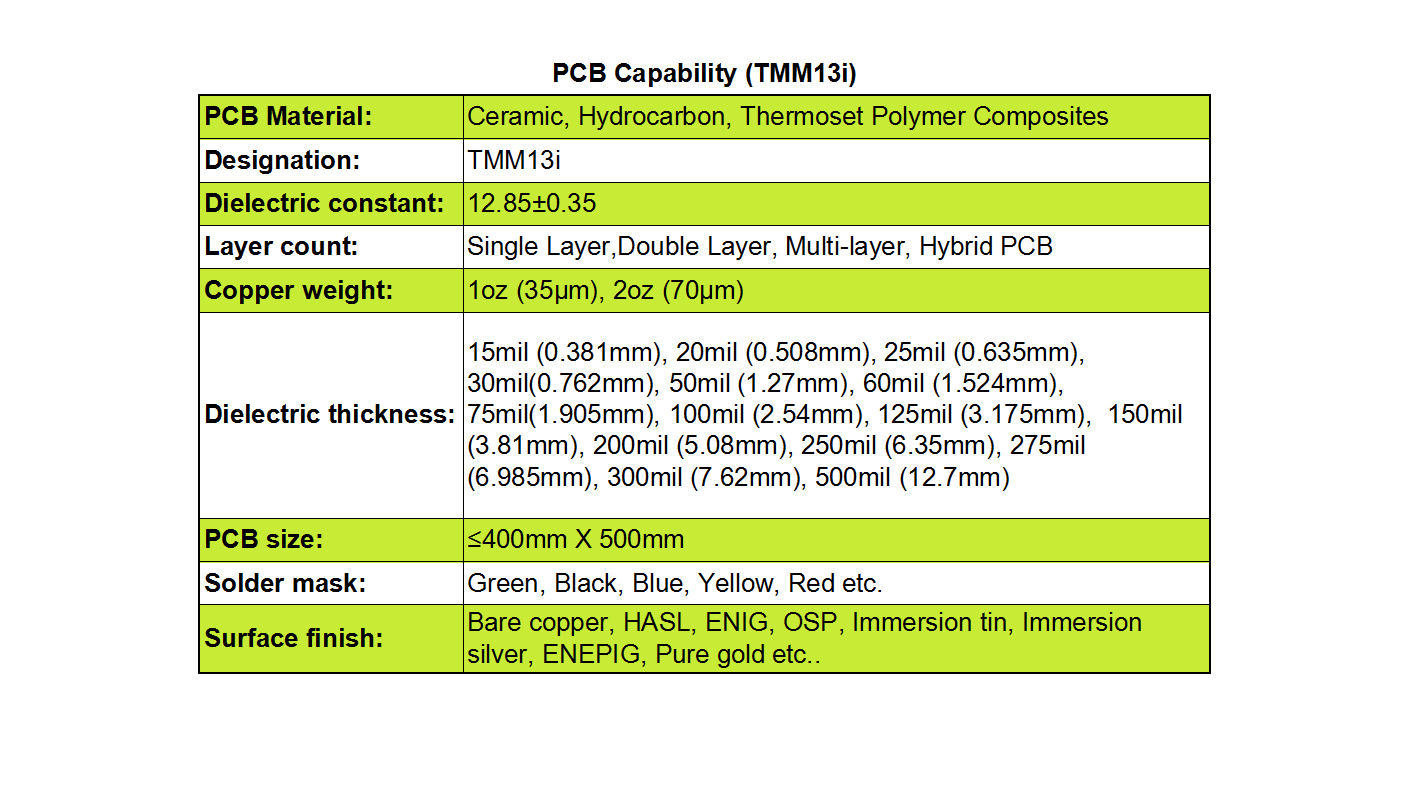

PCB Manufacturing Capabilities with TMM13i

We produce:

Single-layer, double-layer, multilayer, and hybrid PCBs

Copper weights: 1 oz (35 µm) and 2 oz (70 µm)

Dielectric thickness: 15 mil (0.381 mm) to 500 mil (12.7 mm)

Max board size: 400 mm x 500 mm

Solder mask colors: green, black, blue, yellow, red

Surface finishes: Bare copper, HASL, ENIG, OSP, immersion tin, immersion silver, ENEPIG, pure gold

Applications

TMM13i PCBs are ideal for:

Chip testers

Dielectric polarizers

Lenses and filters

Couplers

RF and microwave circuits

Satellite communication systems

Thank you for reading. Follow us for more updates on high-frequency PCB solutions.