TMM3 Microwave PCBs Deliver Reliability for Demanding RF Applications

September 25, 2025

September 25, 2025

In the world of high-frequency electronics, not all circuit materials can withstand the demands of precision stripline and microstrip designs. Rogers TMM3 thermoset microwave laminates stand out by combining the benefits of ceramic and PTFE-based materials—without the complex manufacturing requirements.

Whether you're developing satellite communications, GPS antennas, or high-power amplifiers, TMM3 offers a robust foundation for applications where electrical stability and plated through-hole reliability are critical.

What Is TMM3?

TMM3 is a ceramic thermoset polymer composite engineered by Rogers Corporation for use in stripline and microstrip circuits. It bridges the gap between traditional PTFE and ceramic laminates, offering strong performance without specialized processing. Its thermoset resin system ensures excellent wire-bonding reliability and resists pad lifting or substrate deformation.

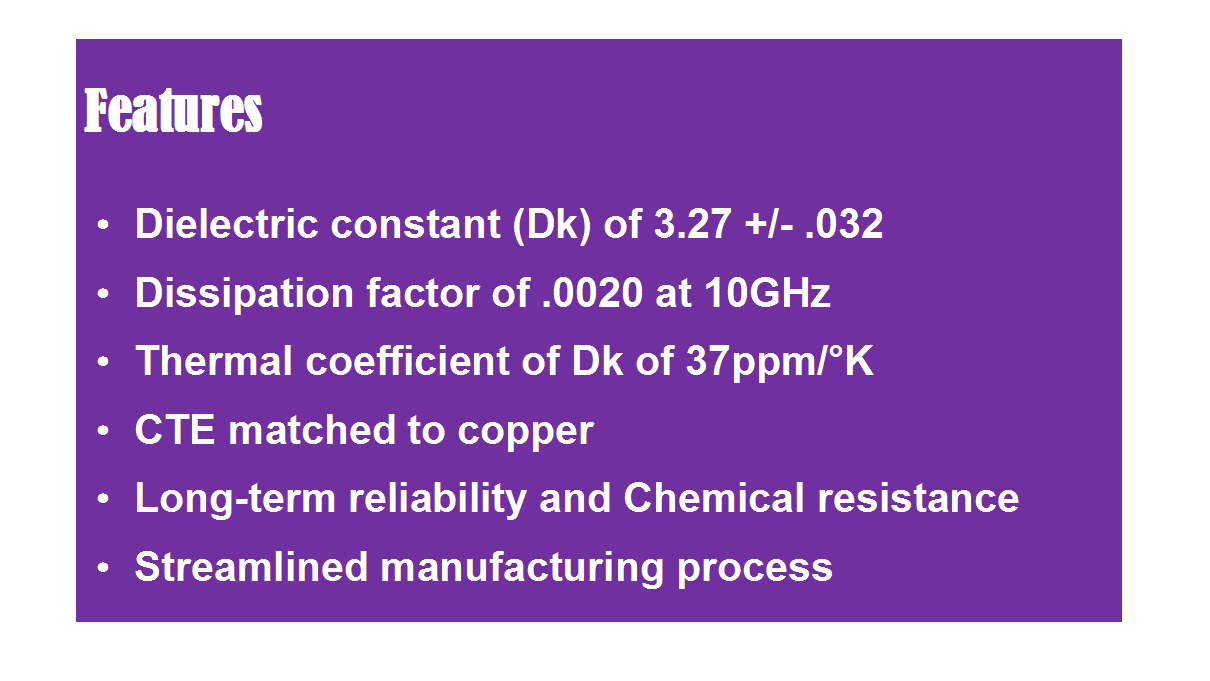

Key Features & Benefits

1.Stable Dielectric Constant

With a Dk of 3.27 ±0.032, TMM3 ensures consistent impedance and signal integrity across your design.

2. Low Loss at High Frequencies

Insertion loss measures only:

2.2 dB/inch at 5 mil thickness

1.8 dB/inch at 9.4 mil thickness

(at 77 GHz)

3. Thermal Stability

The thermal coefficient of Dk is 37 ppm/°K, ensuring stable electrical behavior across temperature variations.

4. Matched CTE to Copper

The laminate’s thermal expansion closely matches that of copper, reducing the risk of plated through-hole failure under thermal stress.

5.Mechanical Durability

TMM3 resists creep, cold flow, and common process chemicals, improving yield and long-term reliability.

6.Streamlined Manufacturing

No sodium napthanate treatment is required prior to electroless plating, simplifying production and reducing steps.

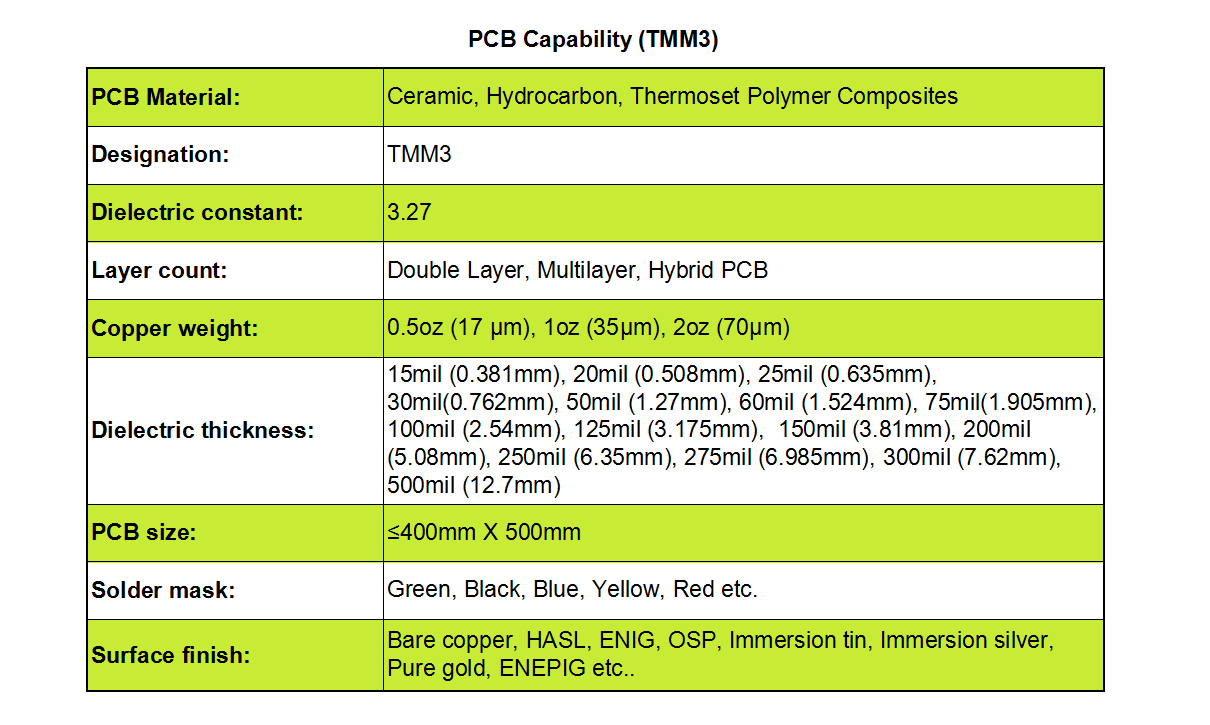

TMM3 PCB Capabilities

We support a full suite of TMM3 PCB manufacturing options:

Layer Configurations: Double-layer, multilayer, and hybrid boards

Copper Weight: 0.5 oz (17µm), 1 oz (35µm), or 2 oz (70µm)

Thickness Range: 15 mil (0.381mm) to 500 mil (12.7mm)

Max Board Size: 400mm × 500mm

Solder Mask Colors: Green, black, blue, yellow, red, and more

Surface Finishes: ENIG, HASL, Immersion Silver, Immersion Tin, ENEPIG, OSP, Bare Copper, and Pure Gold

Typical Applications

TMM3 is trusted in a range of high-performance systems, including:

RF & Microwave Circuits

Power Amplifiers & Combiners

Filters & Couplers

Satellite Communication Systems

GPS & Patch Antennas

Dielectric Polarizers & Lenses

Chip and Component Test Systems

Why Design with TMM3?

TMM3 brings together electrical consistency, thermal reliability, and mechanical durability—making it an ideal substrate for mission-critical RF and microwave applications. Its compatibility with standard PCB processes further lowers the barrier to high-performance design.

Interested in using TMM3 in your next project?Reach out for technical support or a project quote.