Wangling TP High Frequency PCBs A Unique Thermoplastic Solution for Demanding Applications

October 9, 2025

October 9, 2025

In the world of high-frequency materials, true innovation is rare. Wangling’s TP series breaks the mold as a unique thermoplastic laminate that combines ceramic and Polyphenylene Oxide (PPO) resin—without traditional fiberglass reinforcement. This distinctive composition allows for unprecedented control over dielectric properties, making TP materials a top choice for specialized, high-reliability applications.

What Makes TP Material Unique?

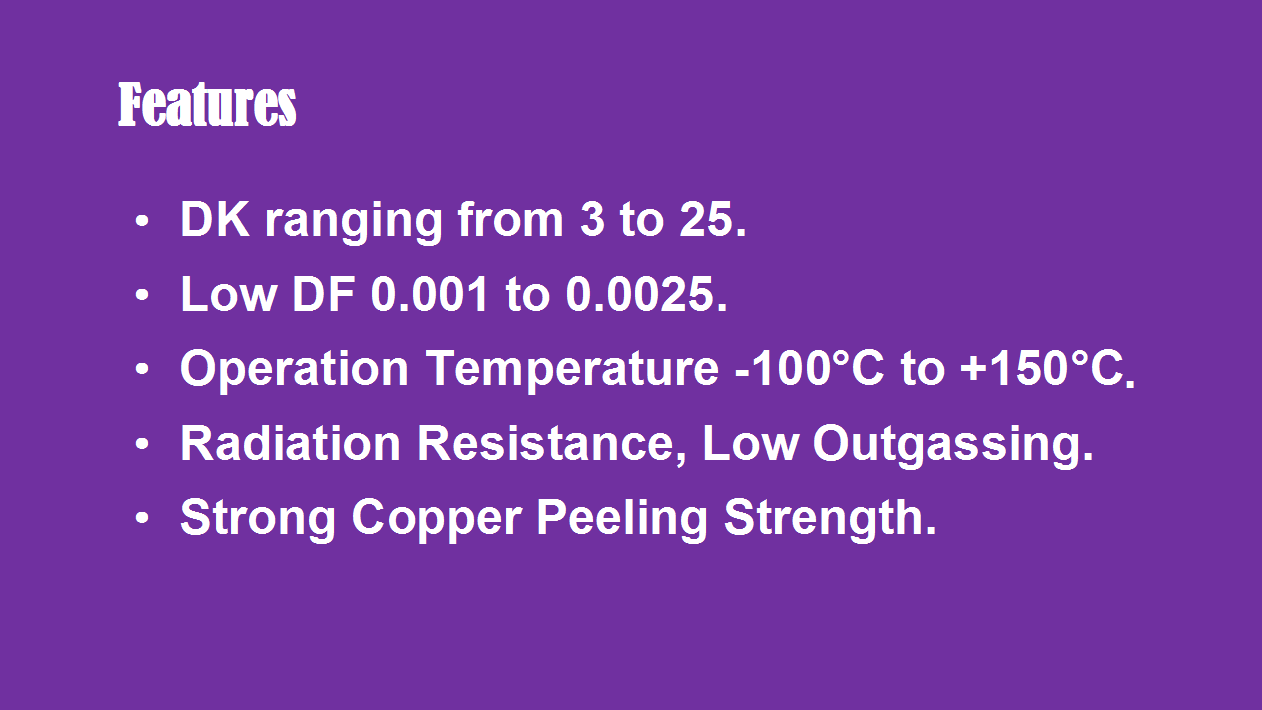

TP stands out as a high-frequency thermoplastic where the dielectric layer is composed solely of ceramics and PPO resin. This fiberglass-free construction offers several key advantages:

Tunable Dielectric Constant: Dk can be precisely adjusted between 3 and 25 by modifying the ceramic-to-resin ratio

Excellent Dielectric Performance: Low loss and stable electrical properties across a broad frequency range

High Reliability: Superior copper adhesion compared to vacuum-coated ceramic substrates

Robust Environmental Performance: Radiation-resistant and low outgassing, suitable for harsh environments

Key Material Properties

Wide Dk Range: Common values include 3.0, 4.4, 6.0, 6.15, 9.2, 9.6, 10.2, 11, 16, and 20

Low Dielectric Loss: Minimal increase within the 10 GHz range

Broad Temperature Range: Operates from -100°C to +150°C with excellent low-temperature performance

Thermal Limitations: Avoid sustained temperatures above 180°C to prevent deformation and performance degradation

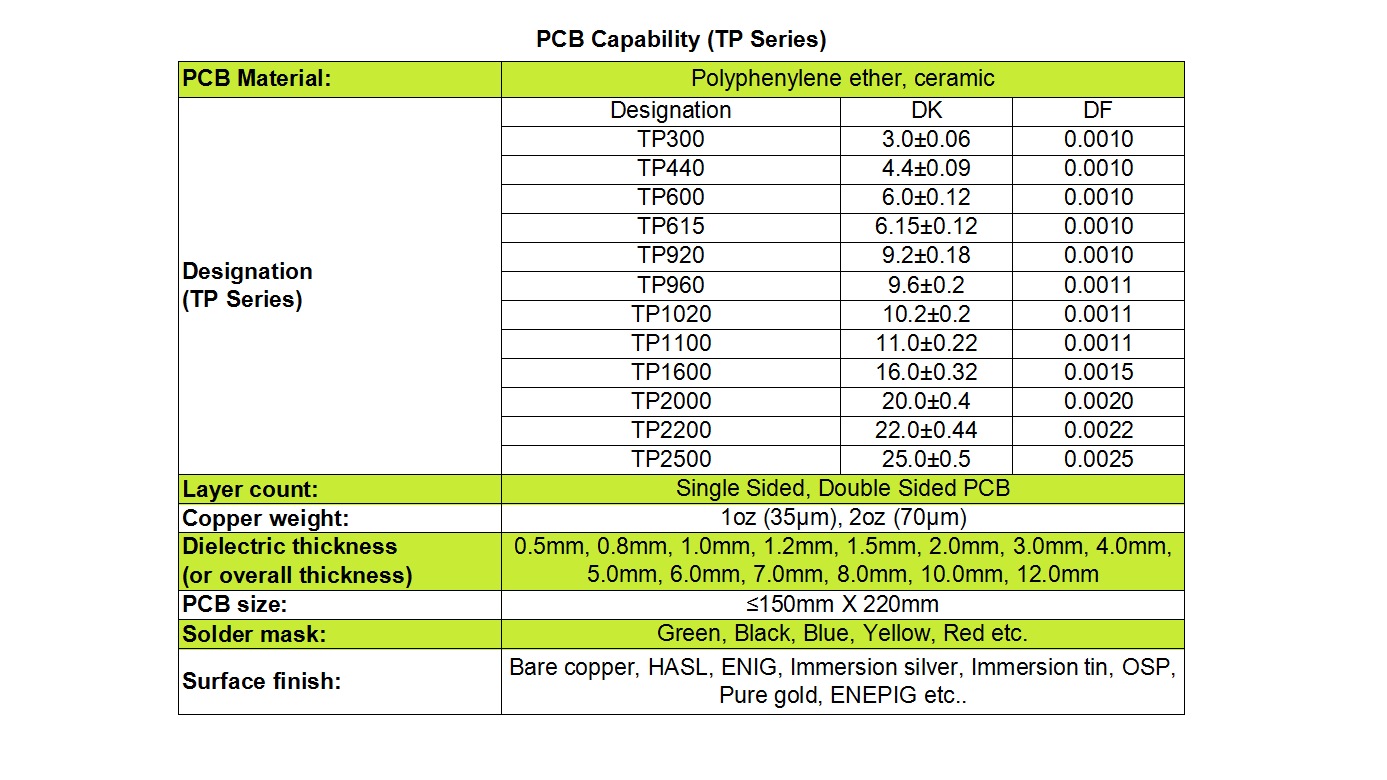

PCB Manufacturing Capabilities with TP Material

We offer specialized fabrication services for TP-based circuits:

Layer Options: Single-sided and double-sided configurations

Copper Weight: 1oz (35µm) and 2oz (70µm)

Dielectric Thickness: Extensive range from 0.5mm to 12.0mm

Maximum Board Size: 150mm × 220mm (due to laminate constraints)

Solder Mask Colors: Green, black, blue, yellow, red, and more

Surface Finishes: HASL, ENIG, Immersion Silver, Immersion Tin, OSP, Pure Gold, ENEPIG, and bare copper

Common Applications

TP high-frequency PCBs are ideal for demanding applications where performance and reliability are critical:

Beidou navigation systems

Missile-borne electronics

Weapon fuzes

Miniaturized antennas

Aerospace and defense systems

High-reliability communications

Why Choose TP Material?

For engineers designing systems that require specific dielectric constants, extreme environmental stability, or miniaturization, TP material offers unique advantages. The ability to precisely tune the Dk between 3 and 25—without fiberglass-related limitations—provides design flexibility unavailable in conventional materials.

While the maximum board size is limited compared to some materials, TP's exceptional electrical performance, temperature resilience, and radiation resistance make it indispensable for specialized military, aerospace, and high-frequency applications.