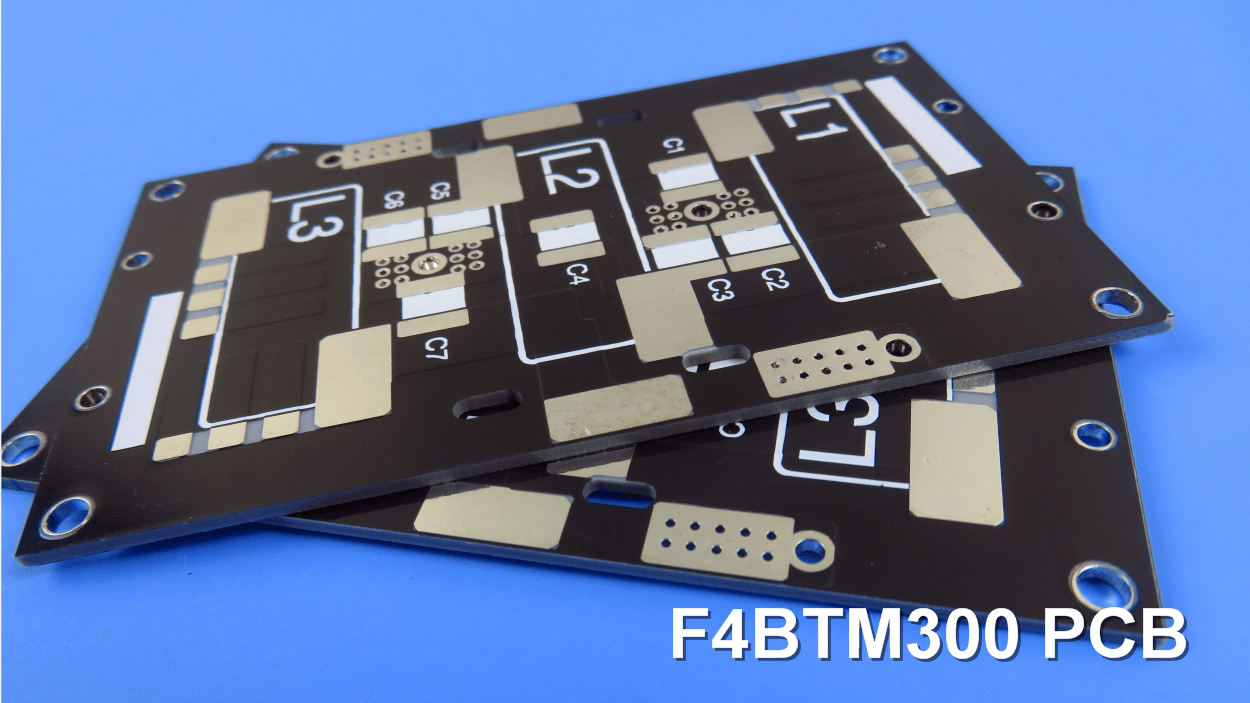

F4BTM High Frequency PCBs A Cost Effective PTFE Based Solution

October 8, 2025

October 8, 2025

In the evolving world of high-frequency circuit design, the demand for materials that deliver both performance and cost efficiency is higher than ever. Wangling’s F4BTM series meets this need with a carefully engineered laminate that combines PTFE resin, fiberglass cloth, and nano-ceramic fillers to offer an ideal balance of electrical and mechanical properties.

Suitable for a wide range of commercial and industrial applications, F4BTM brings together low-loss performance, thermal reliability, and design flexibility—making it an excellent choice for high-volume and high-frequency projects.

What Is F4BTM?

F4BTM is a high-frequency laminate based on an F4BM dielectric layer enhanced with nano-ceramic fillers. This formulation results in:

Higher dielectric constant

Improved heat resistance

Lower thermal expansion coefficient

Higher insulation resistance

Better thermal conductivity

Maintained low-loss characteristics

The series includes two versions:

F4BTM: uses standard ED copper foil

F4BTME: uses reverse-treated foil (RTF) for improved PIM performance, finer line control, and reduced conductor loss

Both share the same high-performance dielectric base, giving designers the flexibility to choose based on application needs.

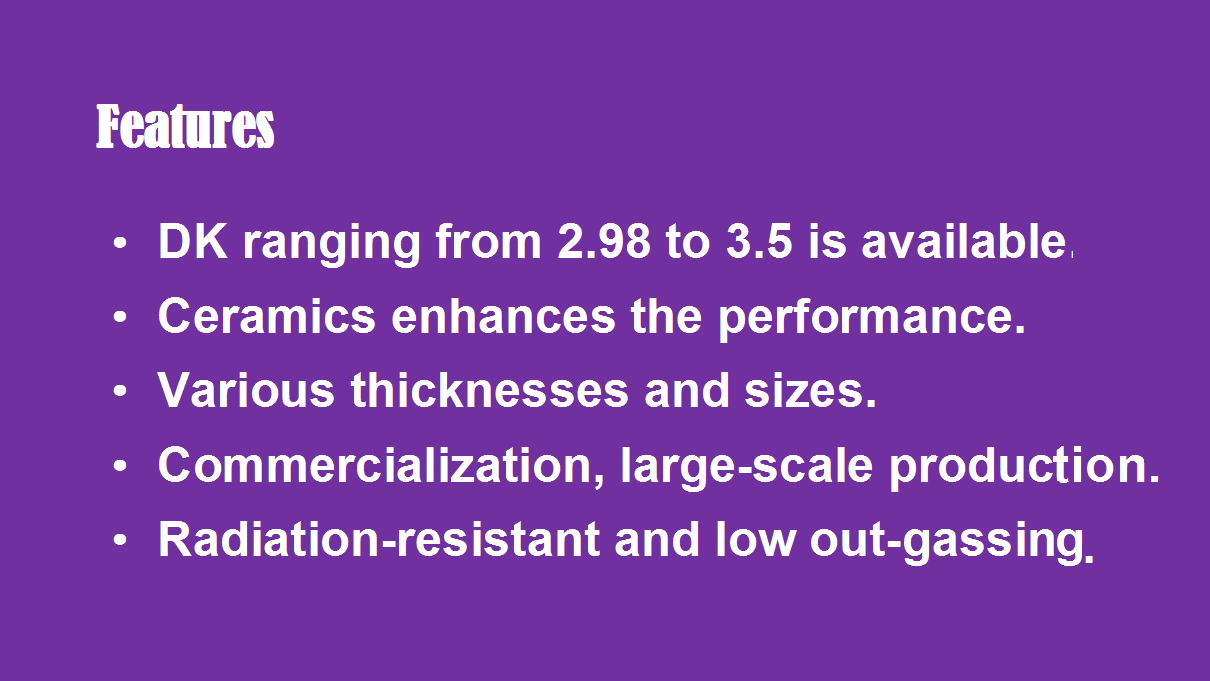

Key Features of F4BTM Laminates

Adjustable Dielectric Constant: Dk values ranging from 2.98 to 3.5

Thermal & Mechanical Stability: Excellent heat resistance and low CTE

Low Loss & High Insulation: Ideal for sensitive RF and microwave circuits

Space-Ready Performance: Radiation-resistant and low out-gassing properties

Scalable & Cost-Effective: Commercialized and ready for large-volume production

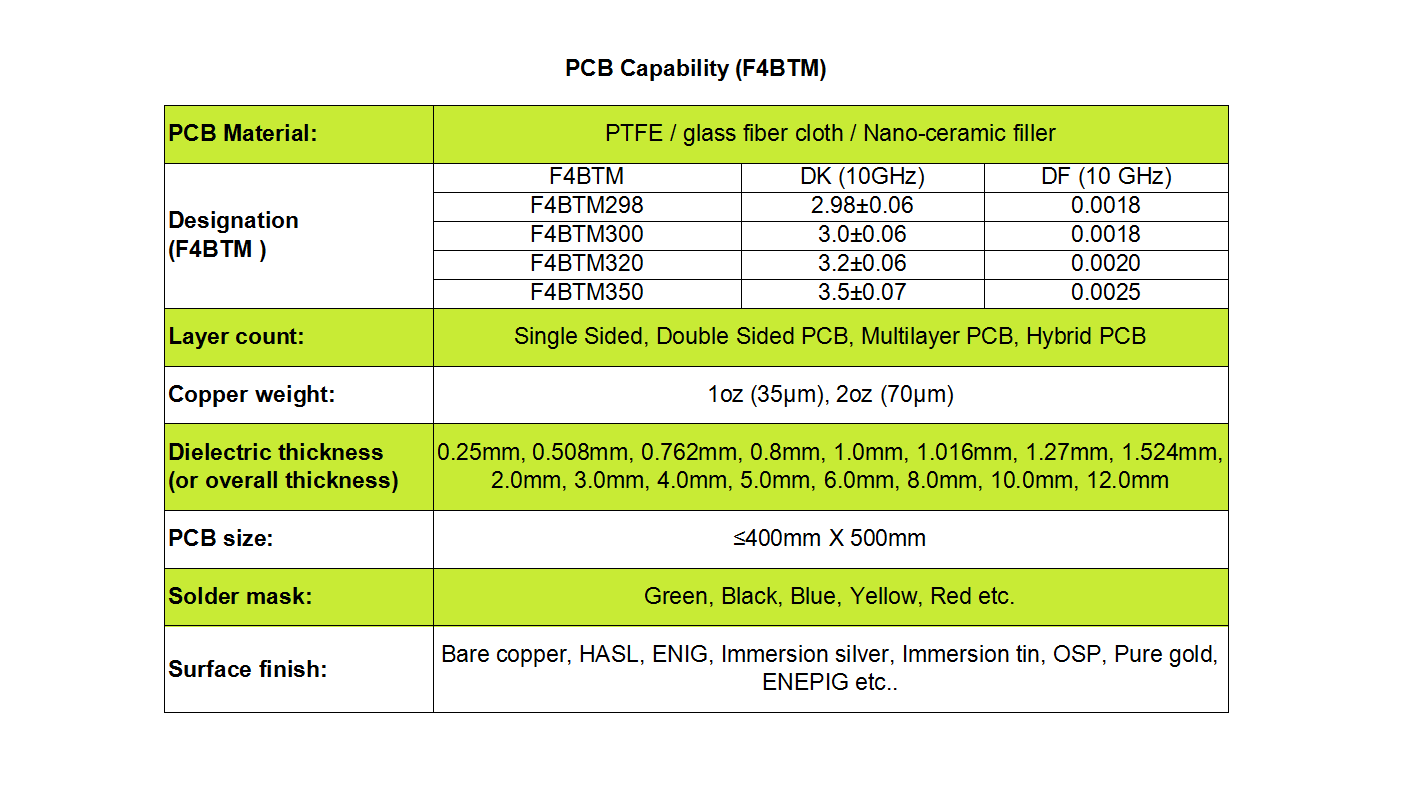

PCB Manufacturing Flexibility

We support full customization of F4BTM-based PCBs with the following options:

Layer Configurations: Single-sided, double-sided, multilayer, and hybrid builds

Copper Weight: 1 oz (35µm) and 2 oz (70µm)

Dielectric Thickness: From 0.25 mm up to 12.0 mm

Max Board Size: Up to 400 mm × 500 mm

Solder Mask Colors: Green, black, blue, yellow, red, and more

Surface Finishes: HASL, ENIG, Immersion Silver, Immersion Tin, OSP, Pure Gold, ENEPIG, and bare copper

Common Applications

F4BTM PCBs are used across a variety of high-frequency and wireless technologies, including:

Antennas

Mobile internet devices

Sensor networks

Radar and millimeter-wave radar systems

Aerospace and satellite navigation

Power amplifiers

Conclusion

Whether you're developing communication systems, radar modules, or IoT devices, F4BTM offers a reliable and cost-efficient substrate that doesn’t compromise on performance. Its combination of PTFE flexibility, ceramic-enhanced stability, and scalable manufacturing makes it a go-to material for next-generation RF designs.

Interested in learning how F4BTM can optimize your next high-frequency project? Contact us to explore design support and prototyping options.