Heavy Copper FPC Flexible PCB with 2 oz Copper on Polyimide

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

General Description:

Introducing our Heavy Copper Flexible Printed Circuit (FPC), specifically designed for AC power systems. This 2-layer polyimide FPC, measuring 0.3mm in thickness, features 2 oz copper. The base laminate is sourced from Shengyi, complemented by a 0.1mm FR-4 stiffener on the back. Manufactured according to IPC 6012 Class 2 standards using provided Gerber data, this FPC ensures high reliability and performance.

Parameter and data sheet

| Size of Flexible PCB | 130.66 X 40.67mm |

| Number of Layers | 2 |

| Board Type | Flexible PCB |

| Board Thickness | 0.30mm |

| Board Material | Polyimide 50µm |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 60℃ |

| PTH Cu thickness | ≥20 µm |

| Inner Iayer Cu thicknes | N/A |

| Surface Cu thickness | 70 µm |

| Coverlay Colour | Yellow |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 µm |

| Stiffener Material | FR-4 |

| Stiffener Thickness | 0.2mm |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 1 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90℃ No peeling after Min. 3 times test |

| Surface Finish | Immersion Gold |

| Thickness of Nickle/Gold | Au: 0.03µm(Min.); Ni 2-4µm |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

.jpg)

Features and Benefits:

Excellent Flexibility: Designed to withstand bending and twisting without compromising performance.

Reduced Volume: Compact design that saves space in applications.

Weight Reduction: Lightweight materials contribute to overall system efficiency.

Consistent Assembly: Reliable manufacturing processes ensure uniform assembly results.

Increased Reliability: Enhanced durability for long-lasting performance.

Whole Soldering Capability: The ends can be fully soldered for improved connections.

Cost-Effectiveness: Affordable solutions for high-quality flexible circuits.

Seamless Processing: Streamlined production processes for efficiency.

On-Time Service: Commitment to meeting delivery timelines.

Quick Lead Time: Fast turnaround of 3-5 days.

Applications

Ideal for various applications including:

General-purpose LED soft light strips

Mobile phone antenna flex boards

Industrial control systems

Temperature controller soft boards

Copper Foils:

We offer two types of copper foils for your flexible circuits: Electro-Deposited (ED) copper foils and Rolled and Annealed (RA) copper foils.

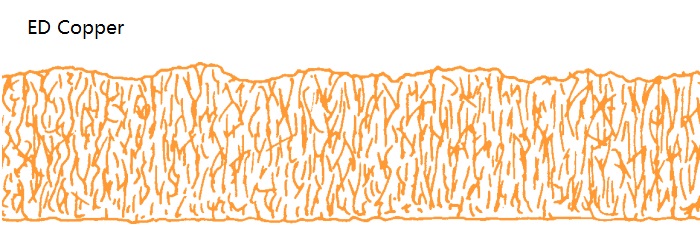

1.Electro-Deposited (ED) Copper Foils:

Produced by depositing copper on a stainless steel drum in a plating tank.

Characterized by a vertical grain structure, offering lower ductility.

Not recommended for dynamic applications.

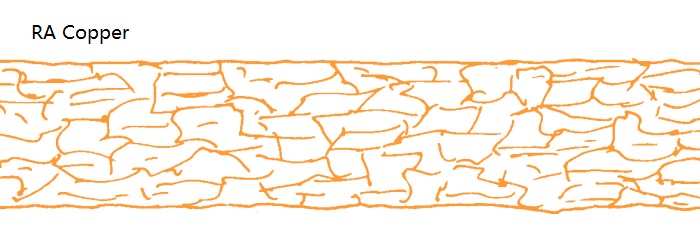

2.Rolled and Annealed (RA) Copper Foils:

Made from electrolytically deposited cathode copper, providing a horizontal grain structure.

Offers superior flexibility and endurance, making it suitable for dynamic applications.

Can be enhanced with electrolytic copper flash for improved adhesion.

More Displays of Heavy Copper Flex:

.jpg)