Hybrid PCB Mixed Material Circuit Board Different Materials Combined PCB RO4350B + FR4 + RT/duroid 5880 with Immersion Gold

(PCBs are custom-made products, the picture and parameters shown are just for reference)

Introduction

Hello Everyone,

Today, we will discuss hybrid PCBs, specifically those that integrate high-frequency materials with epoxy glass.

.jpg)

Understanding Hybrid PCB Structure

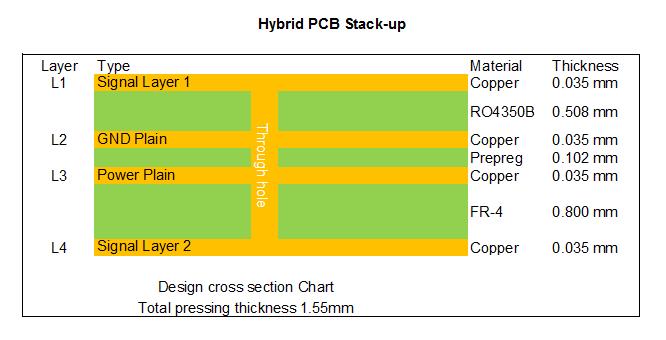

Let’s examine the stack-up to grasp the hybrid configuration:

Layer 1 to layer 2 is the core of RO4350B high frequency material and layer 3 to layer 4 is the core of FR-4 epoxy glass. The 2 cores are bonded by a sheet of adhesive (prepreg).

Types of Hybrid PCB

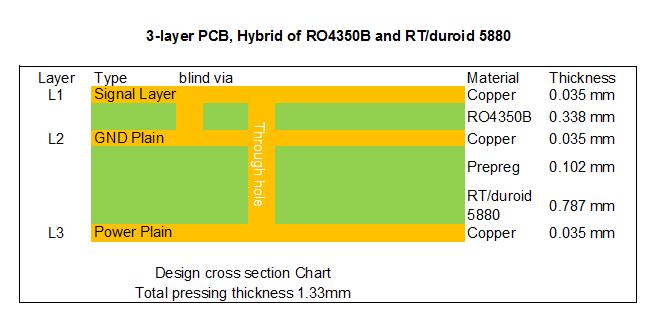

Hybrid PCBs can combine FR-4 with high-frequency materials, as mentioned above. Another type is a mixture of high frequency material with different dielectric constant (DK), for example RT/duroid 5880 and RO4350B etc.

Reasons to Use Hybrid PCBs

There are three primary reasons to opt for high-frequency multilayer PCBs: cost-effectiveness, enhanced reliability, and improved electrical performance.

1.Cost Efficiency: High-frequency materials are generally more expensive than FR-4. By using a hybrid of FR-4 and high-frequency materials, manufacturers can address cost concerns effectively.

2.Reliability Improvement: High Coefficient of Thermal Expansion (CTE) values in PCB materials can lead to reliability issues. Combining low CTE FR-4 with higher CTE materials results in an acceptable composite CTE, thereby enhancing reliability.

3.Tailored Electrical Performance: Different sections of a mixed PCB may require varying levels of electrical performance. For areas needing high performance, high-frequency materials are employed, while less demanding sections can use FR-4. Additionally, using materials with different DK values can improve electrical properties, particularly in combiners and filters.

Why Choose FR-4?

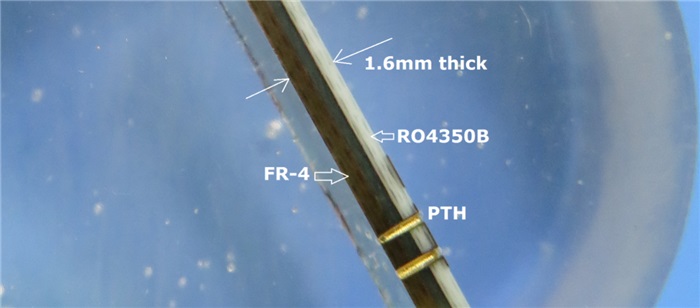

The combination of FR-4 and high-frequency materials is increasingly popular because FR-4 and the vast majority of high frequency materials have little compatibility problems.

To ensure reliable lamination, we select a prepreg sheet of high-frequency material and apply the appropriate pressing cycle. Using an adhesive layer made from the same material simplifies the pressing process.

Our PCB Capability (Hybrid PCB)

|

|

PCB Type: |

Hybrid PCB, Mixed PCB |

Hybrid type: |

RO4350B + FR4; |

RO4003C + FR4; |

|

F4B + FR4; |

|

RT/duroid5880 + FR4; |

|

RT/duroid5880 + RO4350B |

|

RO3000 Series + FR4 |

|

RT/duroid +FR4 |

|

Solder mask: |

Green, Red, Blue, Black, Yellow |

Layer count: |

4 Layer, 6 Layer, Multilayer |

Copper weight: |

1oz (35µm), 2oz (70µm) |

PCB thickness: |

1.0-10mm |

PCB size: |

≤400mm X 500mm |

Surface finish: |

Bare copper, HASL, ENIG, Immersion tin, Immersion silver, OSP, ENEPIG, Pure gold |

Thank you for reading! Feel free to contact us for any PCB inquiries.