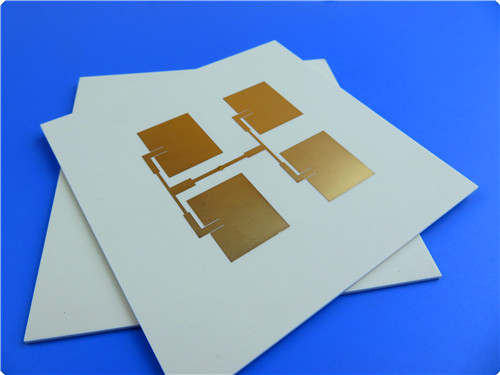

AL₂O₃ Ceramic PCB - Double-Layer Board, 1mm Thickness, Immersion Gold

1.PCB Construction Details

| Base Material | AL2O3 (96%) Ceramic Substrate |

| Layer Count | Double-sided |

| Board Dimensions | 100mm x 100mm ± 0.15mm |

| Minimum Trace/Space | 5/6 mils |

| Minimum Hole Size | 0.4mm |

| Blind Vias | No |

| Finished Board Thickness | 1.1mm |

| Finished Copper Weight | 1oz (1.4 mils) for outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | No |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Testing | 100% Electrical Testing conducted prior to shipment |

2. PCB Stackup: 2-Layer Rigid PCB

Here’s the information formatted into a table:

| Specification | Details |

|---|---|

| Copper Layer 1 | 35 μm |

| Ceramic AL2O3 96% Core | 1.0 mm |

| Copper Layer 2 | 35 μm |

3. PCB Statistics

Components: 16

Total Pads: 33

Through-Hole Pads: 25

Top SMT Pads: 17

Bottom SMT Pads: 0

Vias: 22

Nets: 2

4. Type of Artwork Supplied

Gerber RS-274-X

5. Accepted Standard

IPC-Class-2

6. Availability

Worldwide

7. Typical Applications

(1).Aerospace Field: Ceramic PCBs are ideal for spacecraft and satellites due to their exceptional high-temperature resistance and radiation tolerance, ensuring reliable operation in extreme environments.

(2).Automotive Electronics:Their high-temperature, shock, and corrosion resistance make ceramic PCBs suitable for automotive electronic control units and safety systems, enhancing vehicle safety and reliability.

(3).Energy Sector: In applications like solar panels and wind power generation, ceramic PCBs provide stable electronic support, ensuring efficient operation and long-term stability for renewable energy devices.

(4).IoT Technology: With the growing demand for miniaturization and high performance, ceramic PCBs are perfect for IoT devices in smart homes and transportation, driving the development of IoT technology.

(5).High-Power Electronics: They are essential in RF and microwave circuits, medical equipment, and industrial applications, offering stable support for high-temperature environments.

8. Introduction to AL2O3 96% Ceramic Material

AL₂O₃ ceramic laminates consist mainly of aluminum oxide (AL₂O₃), comprising over 96% of the material. Small amounts of additives like yttrium oxide (Y2O3) and magnesium oxide (MgO) enhance performance.

Density: 3.5-3.9 g/cm³, indicating substantial mass.

Hardness: Exceeds 9 on the Mohs scale, offering excellent wear resistance.

Thermal Conductivity: Typically 20-30 W/(m·K), providing commendable insulation.

Coefficient of Linear Expansion: 6-8×10^-6/°C, showcasing strong thermal stability.

9. Features

Density: ≥ 3.7 g/cm³

Warpage: ≤ 2

Surface Roughness: 0.2-0.75 μm

Thermal Conductivity: 24 W/mK

Coefficient of Linear Expansion: 6.5-8.0 × 10^-6/K

Dielectric Constant at 1MHz: 9-10

Breaking Voltage: 17 kV/mm

Volume Resistivity: 10-14 Ω·cm

Flexural Strength: 350 MPa

10. Benefits

High Resistance: Reduces current loss and heat generation.

Outstanding High-Frequency Performance: Ideal for communications and signal processing.

Effective Heat Dissipation: Prevents overheating.

Chemical Stability: Resistant to corrosion for long-term reliability.

Mechanical Strength: Endures vibration and high temperatures.

Precision Circuits: Maintains high accuracy during manufacturing.

High Current-Carrying Capacity: Handles large currents with minimal temperature increase.

Superior Insulation: Offers high voltage resistance for safety.

Strong Bonding: Ensures firm adherence between copper foil and ceramic substrate, preventing delamination.