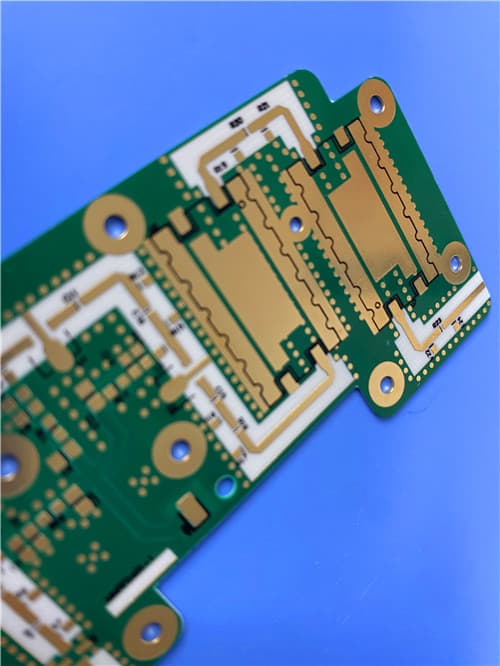

CLTE-AT 2-Layer 5mil Ultra-Thin Ceramic PTFE PCB with Immersion Gold

1.Introduction

CLTE-A laminates represent the commercial version of the CLTE™ product line.CLTE-AT laminates use the common building blocks developed with CLTE-XT™ laminates, but with some changes to make the product more affordable. This results in a higher dielectric constant (3.00) and a slightly different thickness than the CLTE-XT laminates.

CLTE-AT micro dispersed ceramic PTFE composites utilize a woven fiberglass reinforcement to provide the highest degree of dimensional stability, critical in multilayer designs. CLTE-AT laminates are in a “League of their Own” for registration when utilizing thin substrates (i.e. 0.005” and 0.010”).

CLTE-AT laminates have “Best-in-Class” Insertion Loss (S21) and Loss Tangent(0.0013) in the commercial marketplace and second only to CLTE-XT laminates.

Rogers’ CLTE-AT laminates were designed to provide a quality peel strength without having to resort to the utilization of the lossier, rougher coppers prevalent in competitive products to achieve acceptable copper adhesion.

CLTE-AT laminates have Low CTE xyz and Very Low TCEr for applications that require Electrical Phase Stability, Dk Stability, and Mechanical Stability well over a -55 to 150°C Operating Temperature. CLTE-AT laminates continue the competitive advantages of CLTE laminates (dimensional stability, low absorption of moisture and processing chemicals, ease of processability). The higher thermal conductivity of CLTE-AT laminates improve heat transfer relative to alternative materials and enable better power handling.

2.Key Features and Benefits

Superior signal integrity

Ceramic/PTFE Microwave Composite

Mechanically more robust and more dimensionally stable than alternatives

Lowest Insertion Loss in Commercial Class

Excellent thermal/mechanical performance characteristics

Very Low Loss Tangent (0.0013)

Electrical Phase Stability vs. Temperature

High Thermal Conductivity of 0.64 W/mk

Tight Dielectric Constant (±0.04) and Thickness Tolerance

Woven glass reinforcement

Excellent Thermal Stability of Dk and Df

Phase Stability across temperature

High Degree of Dimensional Stability required for complex, multilayer boards

Excellent CTE in X,Y and Z with value of 8, 8 and 20 ppm/˚C respectively

Physical Properties

Flammability of UL 94-V0

Moisture Absorption of 0.03%

Outgassing, Total Mass Lost(TML) 0.04%; Collected Volatiles 0; Water Vapor Recovered 0

3.PCB Details

| Specification | Value |

|---|---|

| Base Material | CLTE-AT |

| Layer Count | Double sided |

| Board Dimensions | 56mm × 99mm (±0.15mm) |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 0.2mm |

| Finished Cu Weight | 1oz (1.4 mils) |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | Black |

| Bottom Silkscreen | No |

| Top Solder Mask | Green |

| Bottom Solder Mask | No |

| Electrical Test | 100% prior to shipment |

4.PCB Stackup (2-Layer Rigid Structure)

2-layer rigid PCB

Copper layer 1 – 35 μm

CLTE-AT substrate – 0.13 mm (5mil)

Copper layer 2 – 35 μm

5.PCB Statistics

Components: 25

Total Pads: 39

Thru Hole Pads: 13

Top SMT Pads: 26

Bottom SMT Pads: 0

Vias: 24

Nets: 2

6.Typical Applications

Chip testers

Dielectric polarizers

Satellite communication systems

GPS antennas, and patch antennas

7.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide