Rogers RO4350B High-Frequency PCB – Cost-Effective Solution for RF and Microwave Applications

In the realm of RF and microwave circuit design, the choice of PCB material is crucial for achieving optimal performance and cost efficiency. The Rogers RO4350B High-Frequency PCB is a proprietary woven glass-reinforced hydrocarbon/ceramic material that combines the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. This makes it an ideal choice for a wide range of high-frequency applications, offering excellent performance at a fraction of the cost of traditional microwave laminates.

1.Key Features of RO4350B PCB

(1).Low Dielectric Constant (DK 3.48 ±0.05): The RO4350B material provides tight control over dielectric constant, ensuring consistent signal integrity and minimal signal loss, even at high frequencies.

(2).Low Dissipation Factor (0.0037): The low dissipation factor ensures efficient signal transmission, making it suitable for high-frequency applications that require minimal signal loss.

(3).Excellent Dimensional Stability: The thermal coefficient of expansion (CTE) of RO4350B is similar to that of copper, providing excellent dimensional stability. This is particularly beneficial for mixed dielectric multi-layer board constructions.

(4).High Thermal Stability: With a Tg (glass transition temperature) of >280°C (536°F), the RO4350B material remains stable over a wide range of processing temperatures, ensuring reliable performance in severe thermal conditions.

(5).Low Moisture Absorption (0.06%): The material’s low moisture absorption ensures stable performance in humid or wet environments, making it suitable for outdoor and automotive applications.

(6).Cost-Effective Manufacturing: RO4350B laminates can be processed using standard epoxy/glass methods, reducing fabrication costs compared to PTFE-based materials. They do not require special through-hole treatments or handling procedures.

2.Benefits:

- Ideal for multi-layer board (MLB) constructions

- Processes like FR-4 at lower fabrication cost

- Excellent dimensional stability

- Competitively priced

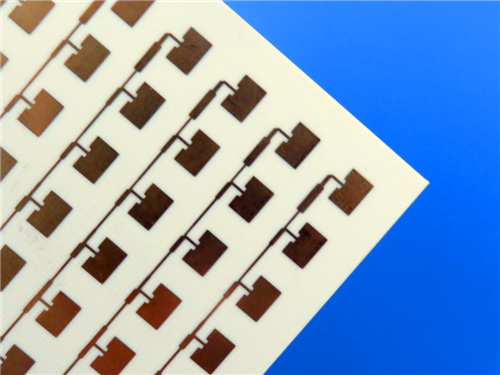

3.PCB Stackup: 2-layer rigid PCB

| Specification | Details |

|---|---|

| Copper Layer 1 | 35 µm |

| Rogers 4003C Core | 0.305 mm (12 mil) |

| Copper Layer 2 | 35 µm |

4.PCB Construction details:

- Board dimensions: 340 mm x 340 mm=1PCS, +/- 0.15mm

- Minimum Trace/Space: 4/5 mils

- Minimum Hole Size: 0.25mm

- No Blind vias.

- Finished board thickness: 0.2mm

- Finished Cu weight: 1oz (1.4 mils) outer layers

- Via plating thickness: 20 μm

- Surface finish: Immersion Gold

- Top Silkscreen: No

- Bottom Silkscreen: No

- Top Solder Mask: No

- Bottom Solder Mask: No

- 100% Electrical test used prior to shipment

5.PCB Statistics:

Components: 16

Total Pads: 60B

Thru Hole Pads: 38

Top SMT Pads: 22

Bottom SMT Pads: 0

Vias: 32

Nets: 2

6.Type of artwork supplied: Gerber RS-274-X

7.Quality standard: IPC-Class-2

8.Availability: worldwide

9.Applications

The RO4350B PCB is well-suited for a variety of high-frequency and RF applications, including:

Cellular Base Station Antennas and Power Amplifiers: Ensures reliable performance in cellular communication systems.

RF Identification Tags: Provides stable signal integrity for RFID applications.

Automotive Radar and Sensors: Ideal for advanced driver-assistance systems (ADAS) and automotive radar.

LNBs for Direct Broadcast Satellites: Ensures precise signal reception and transmission in satellite communication systems.

10.Why Choose RO4350B?

1.Cost-Effective Solution: RO4350B offers the performance of high-end microwave laminates at a fraction of the cost, making it an economical choice for high-frequency applications.

2.Ease of Manufacturing: The material can be processed using standard FR-4 methods, reducing production complexity and costs.

3.Excellent Thermal and Dimensional Stability: The material’s high Tg and low CTE ensure reliable performance in demanding environments.

4.Global Availability: Ready to ship worldwide, ensuring timely delivery for your projects.

11.Conclusion

The Rogers RO4350B High-Frequency PCB is a high-performance, cost-effective material designed to meet the demands of modern RF and microwave applications. With its low dielectric constant, low dissipation factor, and excellent thermal stability, it is an ideal choice for engineers working on cellular base stations, automotive radar, and satellite communication systems.

Whether you're designing for high-frequency RF systems or cost-sensitive applications, the RO4350B PCB offers the reliability and performance you need to bring your projects to life.