RO4533 High Frequency PCB - Rogers 20mil 30mil 60mil Antenna RF PCB for Cellular and WiMAX Applications

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Introducing the Rogers AD1000 Printed Circuit Board, a cutting-edge solution in the realm of high frequency PCBs. Engineered with a high dielectric constant of 10.2 or greater, this woven glass reinforced laminate is designed to facilitate circuit miniaturization while maintaining superior dimensional stability and mechanical robustness compared to traditional low loss materials.

Key Features

High Dielectric Constant: Exceptional performance with a Dk of 10.2.

Thermal Conductivity: 0.81 W/mK for effective heat management.

Copper Peel Strength: High peel strength allows for thinner etched line widths, enhancing design flexibility.

Insertion Loss: Minimal insertion loss for improved signal integrity.

Panel Sizes: Available in larger panel sizes to accommodate diverse applications.

Moisture Absorption: Low moisture absorption at just 0.03%, ensuring reliability in various environments.

Reliability: Excellent CTE values enhance the reliability of ceramic component attachment and PTH.

Typical Applications

The Rogers AD1000 PCB is ideal for a multitude of applications, including:

Aircraft Collision Avoidance Systems (TCAS)

Ground Based Radar Surveillance Systems

Low Noise Amplifiers (LNAs)

Miniaturized Circuitry & Patch Antennas

Power Amplifiers (PAs)

Radar Modules and Manifolds

X-Band and Below Applications

Typical Value of AD1000 Table

| Property | Units | Value | Test Method |

| 1. Electrical Properties | |||

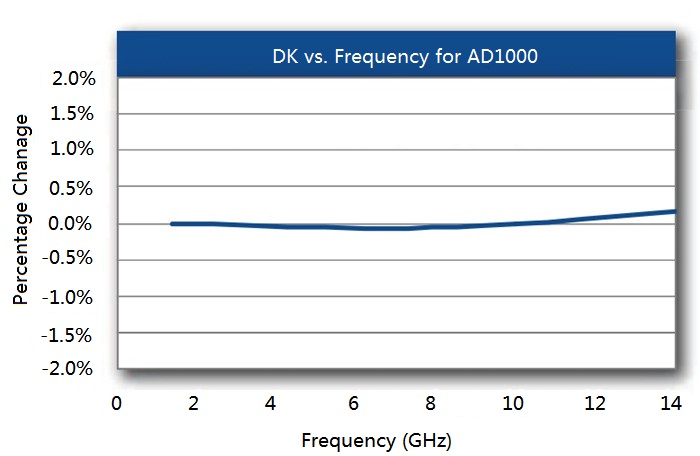

| Dielectric Constant (may vary by thickness) | |||

| @1 MHz | - | IPC TM-650 2.5.5.3 | |

| @ 10 GHz | - | 10.2 | IPC TM-650 2.5.5.5 |

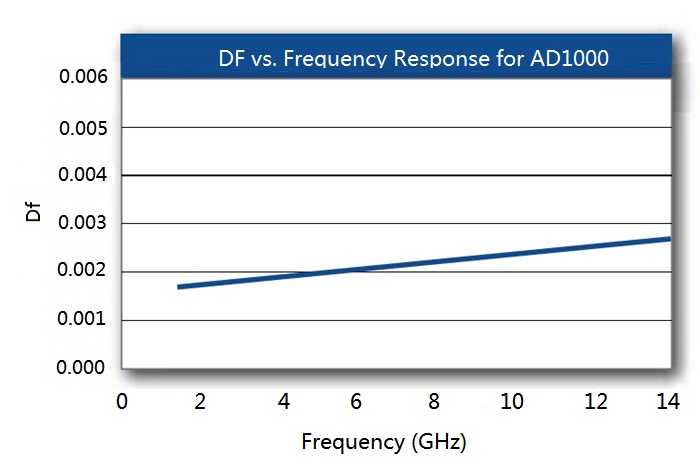

| Dissipation Factor | |||

| @ 1 MHz | - | IPC TM-650 2.5.5.3 | |

| @ 10 GHz | - | 0.0023 | IPC TM-650 2.5.5.5 |

| Temperature Coefficient of Dielectric | - | ||

| TCεr @ 10 GHz (-40-150°C) | ppm/℃ | -380 | IPC TM-650 2.5.5.5 |

| Volume Resistivity | |||

| C96/35/90 | MΩ-cm | 1.40x109 | IPC TM-650 2.5.17.1 |

| E24/125 | MΩ-cm | 5.36x107 | IPC TM-650 2.5.17.1 |

| Surface Resistivity | |||

| C96/35/90 | MΩ | 1.80x109 | IPC TM-650 2.5.17.1 |

| E24/125 | MΩ | 3.16x108 | IPC TM-650 2.5.17.1 |

| Electrical Strength | Volts/mil (kV/mm) | 622 (24.5) | IPC TM-650 2.5.6.2 |

| Dielectric Breakdown | kV | >45 | IPC TM-650 2.5.6 |

| Arc Resistance | sec | >180 | IPC TM-650 2.5.1 |

| 2. Thermal Properties | |||

| Decomposition Temperature (Td) | |||

| Initial | ℃ | >500 | IPC TM-650 2.4.24.6 |

| 5% | ℃ | >500 | IPC TM-650 2.4.24.6 |

| T260 | min | >60 | IPC TM-650 2.4.24.1 |

| T288 | min | >60 | IPC TM-650 2.4.24.1 |

| T300 | min | >60 | IPC TM-650 2.4.24.1 |

| Thermal Expansion, CTE (x,y) 50-150ºC | ppm/℃ | 8, 10 | IPC TM-650 2.4.41 |

| Thermal Expansion, CTE (z) 50-150ºC | ppm/℃ | 20 | IPC TM-650 2.4.24 |

| % z-axis Expansion (50-260ºC) | % | IPC TM-650 2.4.24 | |

| 3. Mechanical Properties | |||

| Peel Strength to Copper (1 oz/35 micron) | |||

| After Thermal Stress | lb/in (N/mm) | >12 (2.1) | IPC TM-650 2.4.8 |

| At Elevated Temperatures (150º) | lb/in (N/mm) | 13.6 (2.4) | IPC TM-650 2.4.8.2 |

| After Process Solutions | lb/in (N/mm) | IPC TM-650 2.4.8 | |

| Young’s Modulus | kpsi (GPa) | 200 (1.38) | IPC TM-650 2.4.18.3 |

| Flexural Strength (Machine/Cross) | kpsi (MPa) | 9.9/7.5 (68/52) | IPC TM-650 2.4.4 |

| Tensile Strength (Machine/Cross) | kpsi (MPa) | 5.1/4.3 (35/30) | IPC TM-650 2.4.18.3 |

| Compressive Modulus | kpsi (GPa) | >425 (>2.93) | ASTM D-3410 |

| Poisson’s Ratio | - | 0.16 | ASTM D-3039 |

| 4. Physical Properties | |||

| Water Absorption | % | 0.03 | IPC TM-650 2.6.2.1 |

| Density, ambient 23ºC | g/cm3 | 3.20 | ASTM D792 Method A |

| Thermal Conductivity | W/mK | 0.81 | ASTM E1461 |

| Flammability | class | Meets V0 | UL-94 |

| NASA Outgassing, 125ºC, ≤10-6 torr | % | NASA SP-R-0022A | |

| Total Mass Loss | % | 0.01 | NASA SP-R-0022A |

| Collected Volatiles | % | 0.00 | NASA SP-R-0022A |

| Water Vapor Recovered | % | 0.00 | NASA SP-R-0022A |

PCB Capabilities (AD1000)

| PCB Capability (AD1000) | |

| PCB Material: | Woven Glass Reinforced PTFE/Ceramic Filled |

| Designation: | AD1000 |

| Dielectric constant: | 10.2 |

| Dissipation Factor | 0.0023 10GHz |

| Layer count: | Double Sided PCB, Multilayer PCB, Hybrid PCB |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| PCB thickness: | 6mil (0.1524mm), 10.5mil (0.2667mm), 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil (0.762mm), 50mil (1.27mm), 59mil (1.499mm ), 125mil ( 3.175mm ), 127mil (3.226mm ) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | Bare copper, HASL, ENIG, Immersion silver, Immersion tin, ENEPIG, Pure gold, OSP etc.. |

Why Choose Us?

Proactive Engineering Design: Prevents issues before they arise in pre-production.

Certified Manufacturing: Our factory is ISO9001, ISO14001, ISO13485, and UL certified.

Automated Optical Inspection (AOI): Ensuring high-quality standards.

Timely Delivery: Over 98% on-time delivery rate.

Extensive Workshop: 16,000㎡ facility with a monthly output capability of 30,000㎡.

Diverse Product Range: Producing 8,000 types of PCBs monthly.

Quick Quotation: Fast CADCAM checking and free PCB quotes.

Proven Experience: Over 18 years in the PCB industry with a customer complaint rate of less than 1%.

Other Available High Frequency PCBs

We also offer a variety of high frequency PCBs, including:

Rogers Materials: RO4350B, RO4003C, RO4730G3, and more.

PTFE Options: F4B with varying dielectric constants.

Taconic Materials: TLX series, RF-10, RF-35, and others.

Explore the Rogers AD1000 Printed Circuit Board today for unparalleled performance in your high frequency applications! For any inquiries or to request a quote, please feel free to contact us.