Single-Sided Flexible Printed Circuit (FPC) – Single Layer Flexible PCB for Bluetooth Headsets and More

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

In the ever-evolving world of electronics, flexibility and reliability are key to designing compact and efficient devices. The Single-Sided Flexible Printed Circuit (FPC) is a cutting-edge solution designed for applications requiring high flexibility, reduced weight, and space-saving designs. Built on SF201 adhesiveless polyimide at 0.15mm thick, this single-layer FPC is ideal for Bluetooth headsets, mobile devices, and other compact electronic applications.

Designed to operate at lower temperatures and with improved dimensional stability, RF-60TC is perfect for miniaturized antennas, high-power amplifiers, and satellite applications. Its low coefficient of thermal expansion (CTE) and reliable plated through holes (PTH) make it ideal for multilayer PCB designs.

Key Features of Single-Sided FPC

1.Excellent Flexibility: The FPC can be freely bent, wound, and folded, making it ideal for applications where space and flexibility are critical.

2.Reduced Volume and Weight: By using FPC, the overall volume and weight of electronic products can be significantly reduced, enabling the development of smaller and lighter devices.

3.High Reliability: The FPC offers increased reliability and consistency in assembly, ensuring stable performance in demanding environments.

4.Controllable Electrical Parameters: The design allows for precise control of electrical parameters, ensuring optimal performance for specific applications.

5.Low Cost: The FPC is a cost-effective solution, offering excellent performance without the high costs associated with traditional rigid PCBs.

6.No Minimum Order Quantity (MOQ): We offer low-cost samples and no MOQ, making it easier for you to test and integrate the FPC into your designs.

7.Material Optionality: The FPC can be customized with different materials to meet specific application requirements.

FPC Specifications

| PCB SIZE | 45 x 33mm=1PCS |

| BOARD TYPE | |

| Number of Layers | Single sided PCB |

| Surface Mount Components | YES |

| Through Hole Components | no |

| LAYER STACKUP | copper ------- 35um(1oz) |

| Polyimide 0.1mm | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 12mil/12mil |

| Minimum / Maximum Holes: | 2.5mm |

| Number of Different Holes: | 1 |

| Number of Drill Holes: | 2 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

| Impedance Control | NO |

| BOARD MATERIAL | |

| Glass Epoxy: | Polyimide 0.1mm, FPC |

| Final foil external: | 1oz |

| Final foil internal: | 0oz |

| Final height of PCB: | 0.1mm ±0.05 |

| PLATING AND COATING | |

| Surface Finish | Electroless nickel over Immersion Gold (ENIG)( 1 µ" over 100 µ" nickel) |

| Solder Mask Apply To: | TOP |

| Solder Mask Color: | Yellow, Coverlay |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Laser cut |

| MARKING | |

| Side of Component Legend | TOP |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo Supplied. |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | None Plated Through Hole(NPTH) |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Applications

The Single-Sided FPC is well-suited for a variety of applications, including:

Bluetooth Headsets: Ideal for compact and lightweight designs.

Mobile Phone Battery Flex Boards: Ensures reliable performance in mobile devices.

Medical Keypad Soft Boards: Suitable for medical devices requiring flexibility and durability.

Thin-Film Switches: Perfect for applications requiring flexible and reliable switching mechanisms.

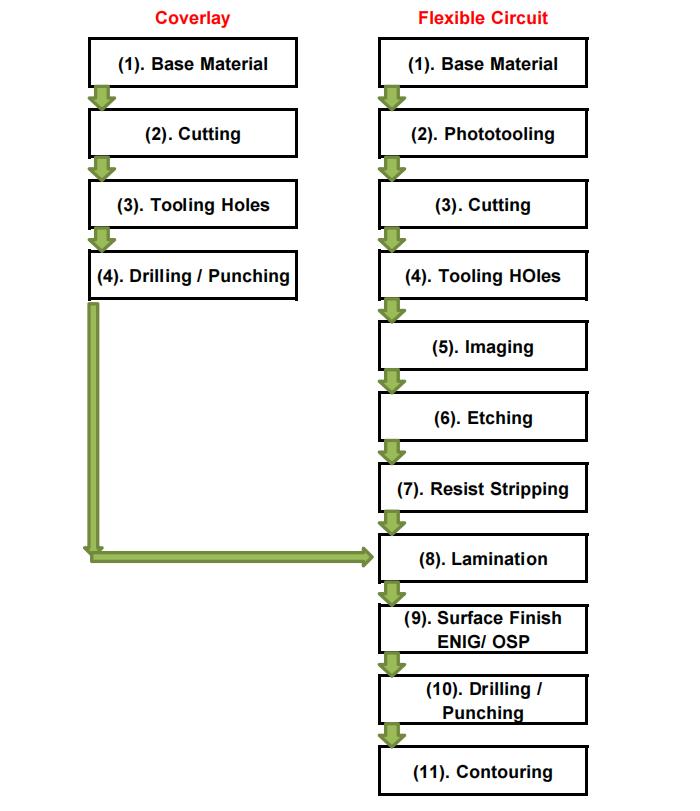

Manufacturing Process

A flow diagram of single-sided flexible PCB is shown as below.

Why Choose Single-Sided FPC?

1.Versatility: The FPC can be used in a wide range of applications, from consumer electronics to medical devices.

2.Cost-Effective: The FPC offers a low-cost alternative to traditional rigid PCBs, making it an economical choice for high-volume production.

3.High Reliability: The FPC is manufactured to IPC 6012 Class 2 standards, ensuring high quality and reliability.

4.Global Availability: Ready to ship worldwide, ensuring timely delivery for your projects.

Parameters (SF201)

| Test Item | Test Method | Unit | IPC Standard |

Typical Value |

| SF201 1012ST | ||||

| Peel Strength 90° | IPC-TM-650,No.2.4.9 Method A Method C |

N/mm | ≥0.525 ≥0.525 |

1.27 1.32 |

| Thermal Stress | IPC-TM-650,No.2.4.13 | - | Pass | Pass |

| Dimensional Stability | IPC-TM-650,No.2.2.4 Method B |

% | ±0.15 | MD: -0.0208 TD: -0.0278 |

| Chemical Resistance | IPC-TM-650,No.2.3.2 | % | ≥80 | >90 |

| Moisture Absorption | IPC-TM-650,No.2.6.2 | % | ≤2 | 1.4 |

| Volume Resistivity | IPC-TM-650,No.2.5.17 | MΩ-cm | ≥10^6 | 2.18×10^9 |

| Surface Resistance | IPC-TM-650,No.2.5.17 | MΩ | ≥10^5 | 1.07×10^7 |

| Dielectric Constant 10GHz | IEC-61189-2-721 | - | ≤3.7 | 3.51 |

| Dissipation Factor 10GHz | IEC-61189-2-721 | - | ≤0.01 | 0.0059 |

| Folding Endurance (MIT method) | JIS C 6471 R0.8×4.9N |

Times | - | >5000 |

| Dielectric Strength | IPC-TM-650,No.2.5.6.1 | V/μm | ≥100 | 120 |

Conclusion

The Single-Sided Flexible Printed Circuit (FPC) is a high-performance, cost-effective solution designed for applications requiring flexibility, reduced weight, and compact designs. With its excellent flexibility, high reliability, and low cost, it is an ideal choice for engineers working on Bluetooth headsets, mobile devices, medical equipment, and more.

Whether you're designing for consumer electronics or specialized industrial applications, the Single-Sided FPC offers the reliability and performance you need to bring your projects to life.

.jpg)

.jpg)