Taconic RF-60A High Frequency PCB 10mil 0.254mm Double Sided RF PCB With Immersion Gold

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Overview of RF-60A

RF-60A is an organic-ceramic laminate from Taconic, belonging to the ORganic CERamic (ORCER) family. It features woven glass reinforcement and combines Taconic's expertise in ceramic fill technology with coated PTFE fiberglass. This material is designed for high-performance applications, exhibiting exceptional interlaminar bond strength and solder resistance. Its unique composition results in low moisture absorption and uniform electrical properties.

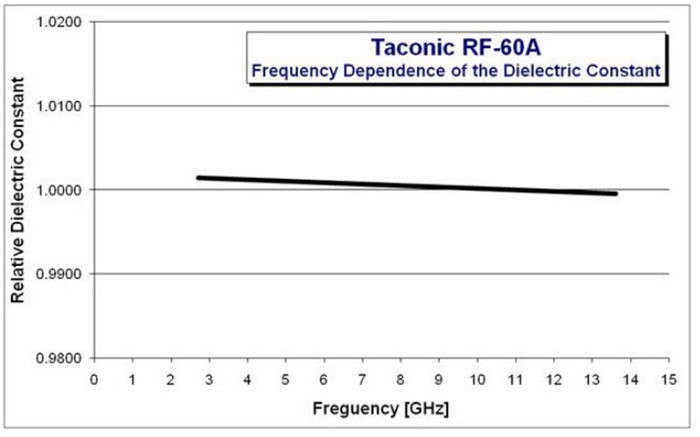

RF-60A's woven glass reinforcement provides excellent dimensional stability and enhances flexural strength. It has low Z-axis expansion, ensuring reliability for plated-through holes in extreme thermal environments. With a dielectric constant of approximately 6.15, RF-60A is ideal for high DK applications that require reduced circuit size and weight. Its low electrical loss factor makes it an excellent choice for RF circuits.

RF-60A laminates comply fully with RoHS and WEEE directives and are compatible with the temperatures needed for new lead-free solders. They can be sheared, drilled, milled, and plated using standard methods for PTFE-woven fiberglass materials, making mass production feasible.

.jpg)

Benefits

Low Moisture Absorption: Reduces the risk of delamination and ensures stability.

Stable DK over Frequency: Maintains consistent dielectric properties across a range of frequencies.

Dimensionally Stable: Ensures reliable performance in various environments.

Low Z-axis Expansion: Enhances reliability for plated-through-hole applications.

High Flexural Strength: Provides durability and resistance to mechanical stress.

Exceptional Interlaminar Bonds: Guarantees strong connections within the laminate.

Typical Applications

1.Power amplifiers

2.Filters & couplers

3.Passive components

4.Antennas

PCB Specifications

Our PCB Capability (RF-60A) |

|

PCB Material: |

Organic-ceramic Woven Fiberglass Reinforced Laminates |

Designation: |

RF-60A |

Dielectric constant: |

6.15 ±0.25 |

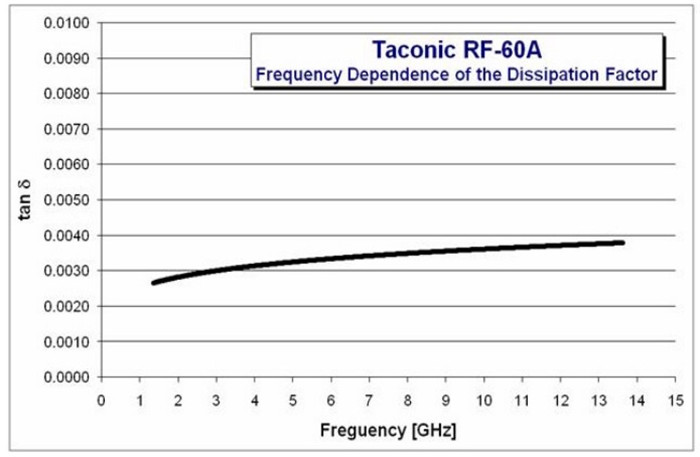

Dissipation Factor |

DF 0.0038@10 GHz |

Thermal Conductivity |

0.4 W/MK |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness: |

10mil (0.254mm), 25mil (0.635mm), 31mil (0.787mm), 50mil (1.27mm), 60mil (1.524mm), 125mil (3.175mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP, Immersion tin etc.. |

Data Sheet of Taconic RF-60A

RF-60A Typical Values |

|||||

Property |

Test Method |

Unit |

Value |

Unit |

Value |

Dk @ 10 GHz |

IPC-650 2.5.5.6 |

|

6.15 |

|

6.15 |

Df @ 10 GHz |

IPC-650 2.5.5.5.1 |

|

0.0038 |

|

0.0038 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.02 |

% |

0.02 |

Dielectric Breakdown |

IPC-650 2.5.6 |

kV |

53 |

kV |

53 |

Dielectric Strength |

ASTM D 149 |

V/mil |

880 |

kV/mm |

35 |

Volume Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm/cm |

9.0 x 108 |

Mohm/cm |

9.0 x 108 |

Surface Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm |

2.28 x 108 |

Mohm |

2.28 x 108 |

Arc Resistance |

IPC-650 2.5.1 |

Seconds |

193 |

Seconds |

193 |

Flexural Strength (MD) |

ASTM D 790 |

psi |

18,300 |

N/mm2 |

126.2 |

Flexural Strength (CD) |

ASTM D 790 |

psi |

14,600 |

N/mm2 |

100.7 |

Tensile Strength (MD) |

ASTM D 3039 |

psi |

19,500 |

N/mm2 |

134.4 |

Tensile Strength (CD) |

ASTM D 3039 |

psi |

16,300 |

N/mm2 |

112.4 |

Young’s Modulus |

ASTM D 3039 |

kpsi |

1,590 |

N/mm2 |

11,000 |

Poisson’s Ratio |

ASTM D 3039 |

|

0.068 |

N/mm2 |

0.068 |

Compressive Modulus |

ASTM D 695 (23°C) |

kpsi |

338 |

|

2,330 |

Peel Strength (1 oz. ED) |

IPC-650 2.4.8 Sec. 5.2.2 (Thermal Stress) |

lbs/in |

8 |

N/mm |

1.4 |

Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

0.68 |

mm/M |

0.68 |

Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

1.05 |

mm/M |

1.05 |

Density (Specific Gravity) |

ASTM D 792 |

g/cm3 |

2.79 |

g/cm3 |

2.79 |

Thermal Conductivity |

ASTM F 433 |

W/M*K |

0.4 |

W/M*K |

0.4 |

CTE (X axis) |

ASTM D 3386 (-30°C - 125°C) |

ppm/°C |

9 |

ppm/°C |

9 |

CTE (Y axis) |

ASTM D 3386 (-30°C - 125°C) |

ppm/°C |

8 |

ppm/°C |

8 |

CTE (Z axis) |

ASTM D 3386 (-30°C - 125°C) |

ppm/°C |

69 |

ppm/°C |

69 |

Outgassing (% TML) |

ASTM E 595* |

% |

0.02 |

% |

0.02 |

Outgassing (% CVCM) |

ASTM E 595* |

% |

0.00 |

% |

0.00 |

Outgassing (% WVR) |

ASTM E 595* |

% |

0.01 |

% |

0.01 |

Flammability Rating |

UL 94 |

|

V-0 |

|

V-0 |