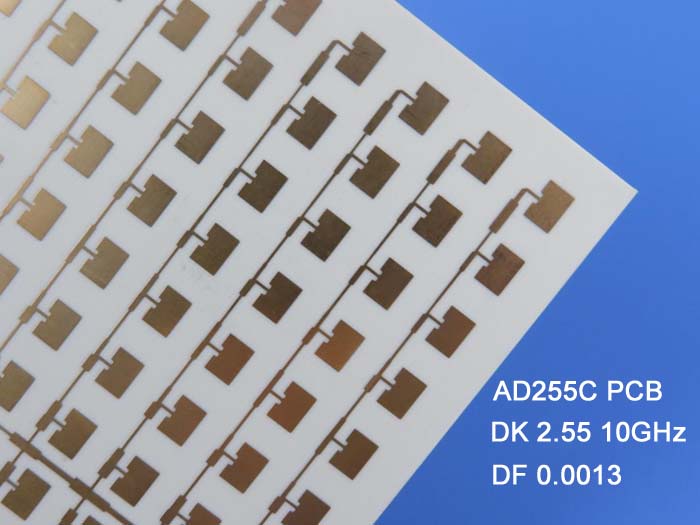

AD255C High Frequency Antenna PCB - 20mil 30mil 40mil 60mil Thickness with Immersion Gold and Immersion Silver

(Note: Printed Circuit Boards are custom-made products. Images and parameters are for reference only.)

General Description

The AD255C High Frequency Antenna PCB is a high-performance circuit board designed for wireless antenna applications. Built on Rogers' AD255C substrates, this PCB features a glass-reinforced, PTFE-based composite that provides a controlled dielectric constant (Dk 2.55) and low loss performance (Df 0.0013 at 10 GHz). With excellent passive intermodulation (PIM) performance, the AD255C PCB is ideal for demanding wireless antenna markets. Available in thicknesses ranging from 20mil to 60mil, it offers immersion gold or immersion silver surface finishes for superior solderability and corrosion resistance.

PCB Capability (AD255C)

| PCB Capability (AD255C) | |

| PCB Material: | Glass-reinforced, PTFE based Composites |

| Designation: | AD255C |

| Dielectric constant: | 2.55 (10 GHz) |

| Dissipation Factor | 0.0013 (10 GHz) |

| Layer count: | Double Sided PCB, Multilayer PCB, Hybrid PCB |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| Dielectric thickness: | 20mil (0.508mm), 30mil (0.762mm), 40mil (1.016mm), 60mil (1.524mm), 125mil (3.175mm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | Immersion gold, HASL, Immersion silver, Immersion tin, OSP, ENEPIG, Bare copper, Pure gold etc.. |

Typical Applications

1.Automotive Telematics Antenna Systems

2.Cellular Infrastructure Base Station Antennas

3.Commercial Satellite Radio Antennas

About Us

We are a leading high-frequency PCB supplier and exporter based in Shenzhen, China, with over 19 years of experience. We specialize in serving industries such as cellular base station antennas, satellite systems, high-frequency passive components, microstrip and band line circuits, millimeter-wave equipment, radar systems, and digital radio frequency antennas. Our high-frequency PCBs are primarily built on materials from Rogers Corporation, Taconic, and Wangling, with dielectric constants ranging from 2.2 to 10.2.

Our Advantages

1.Comprehensive PCB Capabilities: Supporting research, development, sales, and marketing.

2. Certified Manufacturing: PCB products and processes are certified by authorized organizations.

3.Large Production Facility: 16,000㎡ workshop with a monthly output capacity of 30,000㎡.

4.High Production Volume: Capable of producing 8,000 types of PCBs per month.

5.Quick Turnaround: Fast CADCAM checking and free PCB quotations.

6.Flexible Ordering: No minimum order quantity (MOQ); single-piece orders are accepted.

7.Experienced Team: Over 19 years of expertise in high-frequency PCB manufacturing.

8.Prototype to Volume Production: Capable of handling both prototype and large-scale production.

9.Reliability: On-time delivery rate >98%, customer complaint rate <1%.

10. Quality Standards: IPC Class 2 and IPC Class 3 compliant.

Appendix: Typical Values of AD255C

| Electrical Properties | AD255C | Units | Test Conditions | Test Method | |

| PIM (30mil/60mil) | -159/-163 | dBc | Reflected 43 dBm swept tones at 1900 MHz, S1/S1 | Rogers Internal 50 ohm | |

| Dielectric Constant (process) | 2.55 | - | 23°C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 (IPC TM-650 2.5.5.3) |

| Dielectric Constant (design) | 2.60 | - | C-24/23/50 | 10 GHz | Microstrip Differential Phase Length |

| Dissipation Factor (process) | 0.0013 | - | 23°C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Thermal Coefficient of Dielectric Constant | -110 | ppm/ºC | 0°C to 100°C | 10 GHz | IPC TM-650 2.5.5.5 |

| Volume Resistivity | 7.4 x 108 | Mohm-cm | C-96/35/90 | - | IPC TM-650 2.5.17.1 |

| Surface Resistivity | 3.6 x 107 | Mohm | C-96/35/90 | - | IPC TM-650 2.5.17.1 |

| Electrical Strength (dielectric strength) | 911 | V/mil | - | - | IPC TM-650 2.5.6.2 |

| Dielectric Breakdown | >40 | kV | D-48/50 | X/Y direction | IPC TM-650 2.5.6 |

| Thermal Properties | |||||

| Decomposition Temperature (Td) | >500 | ˚C | 2hrs @ 105˚C | 5% Weight Loss | IPC TM-650 2.3.40 |

| Coefficient of Thermal Expansion - x | 34 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion - y | 26 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion - z | 196 | ppm/˚C | - | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Thermal Conductivity | 0.35 | W/mK | - | z direction | ASTM D5470 |

| Time to Delamination | >60 | minutes | as-received | 288˚C | IPC TM-650 2.4.24.1 |

| Mechanical Properties | |||||

| Copper Peel Strength after Thermal Stress | 2.4 (13.6) |

N/mm (lbs/in) | 10s @288˚C | 35 μm foil | IPC TM-650 2.4.8 |

| Flexural Strength (MD/CMD) | 8.8/6.4 (60.7/44.1) | MPa (ksi ) | 25°C ± 3°C | - | ASTM D790 |

| Tensile Strength (MD/CMD) | 8.1/6.6 (55.8/45.5) | MPa (ksi ) | 23°C/50% RH | - | ASTM D3039/D3039-14 |

| Flex Modulus (MD/CMD) | 930/818 (6,412/5,640) | MPa (ksi ) | 25°C ± 3°C | - | IPC-TM-650 Test Method 2.4.4 |

| Dimensional Stability (MD/CMD) | 0.03/0.07 | mils/inch | after etch + bake | - | IPC-TM-650 2.4.39a |

| Physical Properties | |||||

| Flammability | V-0 | - | - | - | UL-94 |

| Moisture Absorption | 0.03 | % | E1/105 +D48/50 | - | IPC TM-650 2.6.2.1 |

| Density | 2.28 | g/cm3 | C-24/23/50 | - | ASTM D792 |

| Specific Heat Capacity | 0.813 | J/g°K | 2 hours at 105°C | - | ASTM E2716 |