RO3003G2 High Frequency PCB for Next-Gen Automotive Radar

September 21, 2025

September 21, 2025

As automotive technology races toward higher levels of automation, the demand for reliable, high-performance radar systems has never been greater. At the heart of these advanced systems lies a critical component: the printed circuit board.

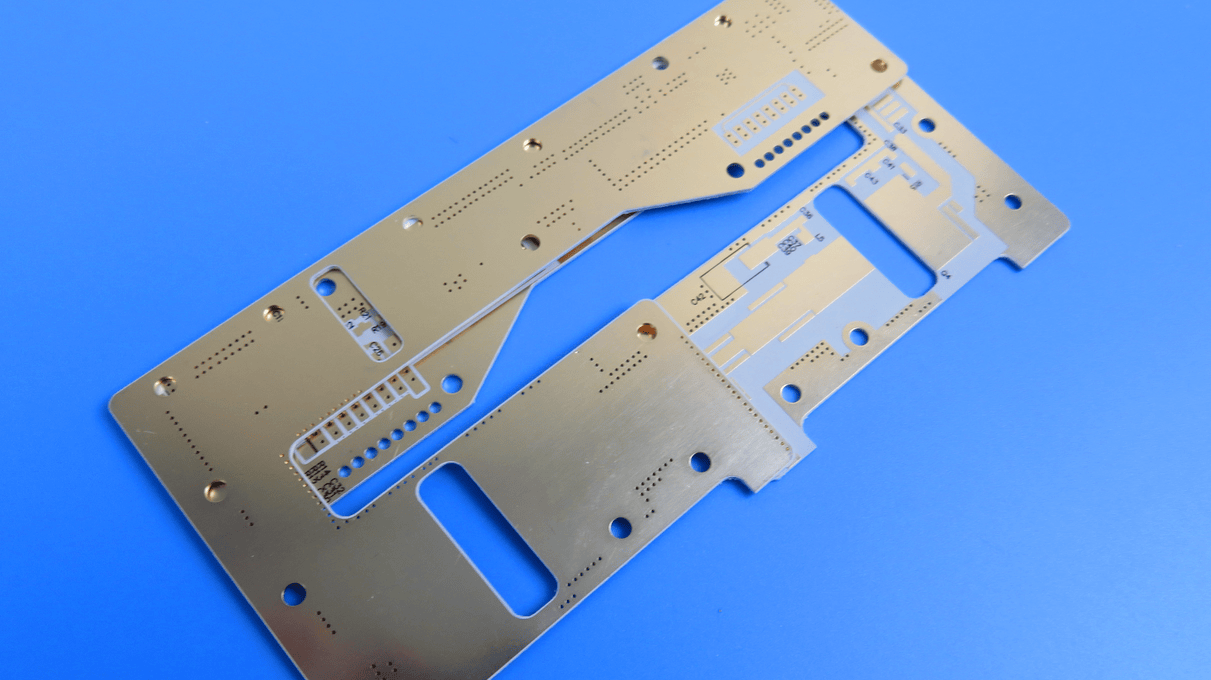

Rogers Corporation, a leader in high-frequency materials, has engineered the RO3003G2 laminate specifically to meet the rigorous demands of next-generation automotive radar and ADAS applications. With its optimized ceramic-filled PTFE composition, RO3003G2 represents a significant evolution in circuit materials for safety-critical automotive electronics.

What Is RO3003G2?

RO3003G2 is an advanced high-frequency circuit material built on Rogers' proven RO3000 series platform. This ceramic-filled PTFE laminate was developed in direct response to industry needs for better performance in millimeter-wave automotive radar systems, particularly those operating at 77 GHz.

By refining the resin and filler composition and incorporating Very Low Profile ED copper, RO3003G2 delivers superior electrical performance while maintaining excellent mechanical stability. This makes it ideally suited for the challenging environments faced by modern automotive electronics.

Key Features and Benefits

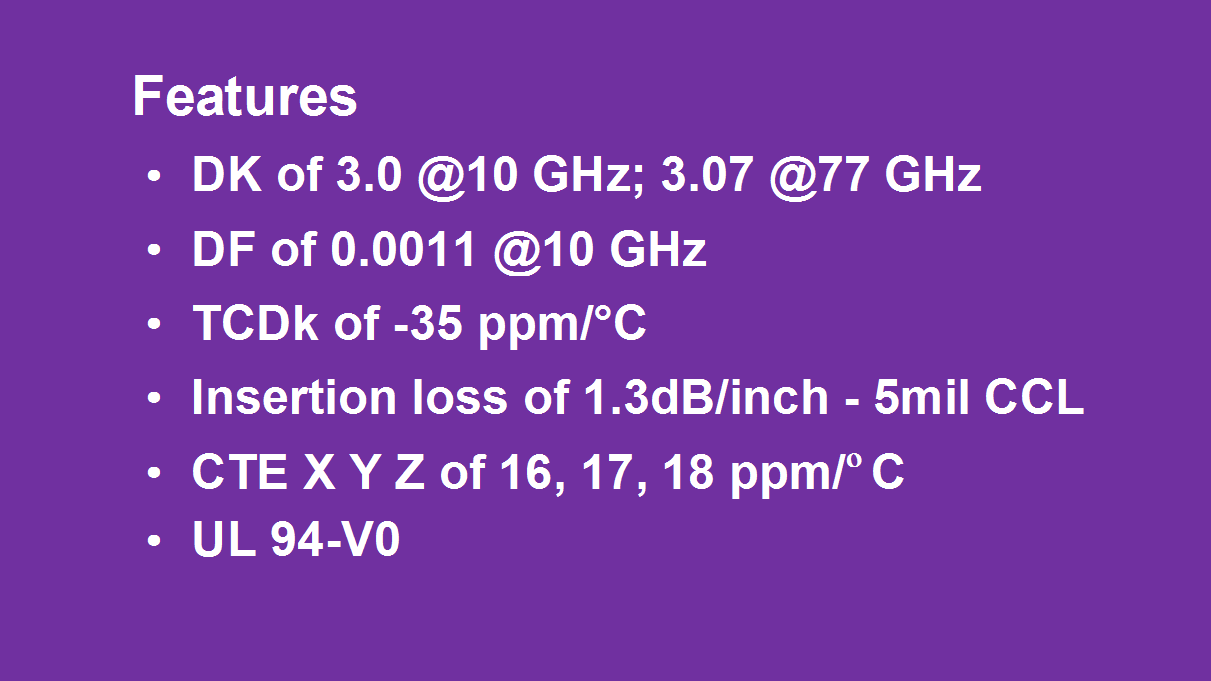

1.Stable Dielectric Properties

Dielectric Constant: 3.00 @ 10 GHz (clamped stripline), 3.07 @ 77 GHz (microstrip differential phase length)

Temperature Coefficient of Dk: -35 ppm/°C @ 10 GHz (-50°C to 150°C)

Ensures consistent electrical performance across temperature variations encountered in automotive environments

2. Ultra-Low Signal Loss

Dissipation Factor: 0.0011 @ 10 GHz

Insertion Loss: 1.3 dB/inch for 5 mil laminates (microstrip differential phase length method)

Minimizes signal degradation in critical millimeter-wave applications

3.Excellent Thermal Management

CTE: 16, 17, and 18 ppm/°C in X, Y, and Z directions respectively

Copper-matched expansion reduces thermal stress in multilayer boards

Prevents delamination and via damage under thermal cycling

4.Reliability and Compliance

UL 94 V-0 Certified for flame resistance

Lead-free manufacturing compatible

Meets automotive industry reliability standards

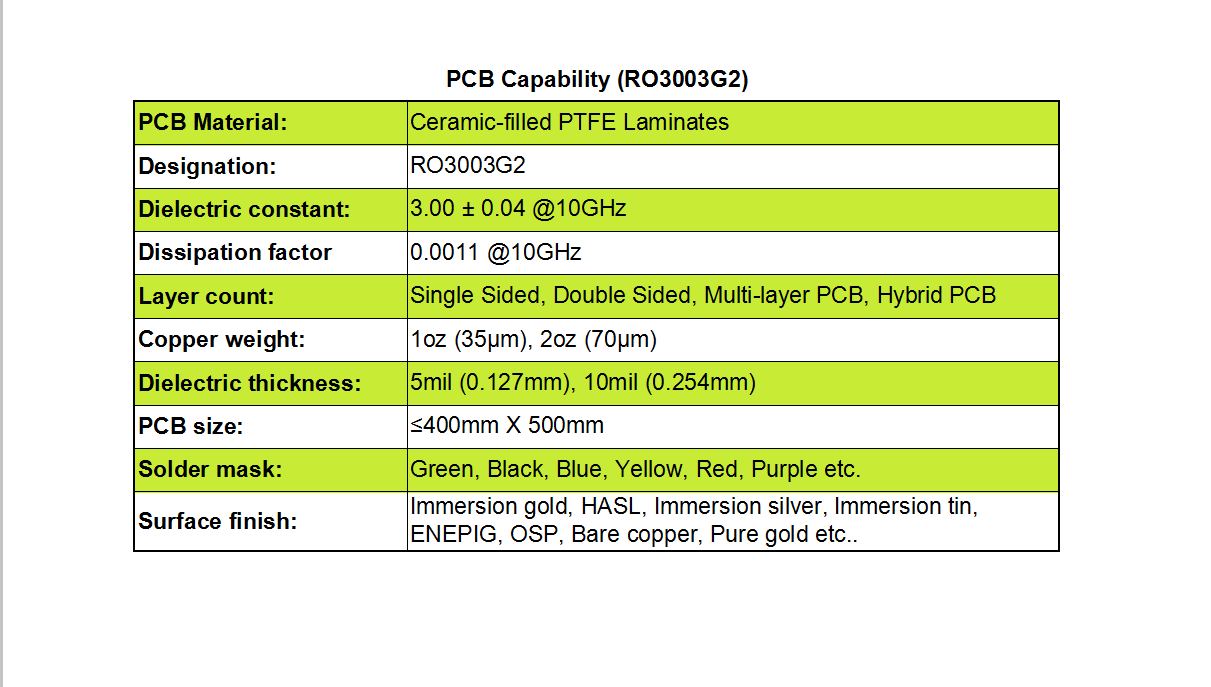

PCB Manufacturing Capabilities

RO3003G2 supports comprehensive PCB configurations to meet diverse design requirements:

Board Types: Single-sided, double-sided, multilayer, and hybrid constructions

Copper Weights: 1 oz (35µm) and 2 oz (70µm) options

Dielectric Thickness: 5 mil (0.127mm) and 10 mil (0.254mm)

Maximum Size: 400mm × 500mm

Solder Mask Colors: Green, black, blue, yellow, red, purple

Surface Finishes: Immersion gold, HASL, immersion silver, immersion tin, ENEPIG, OSP, bare copper, pure gold

Automotive Applications

RO3003G2 is specifically engineered for sophisticated automotive safety systems, including:

Adaptive cruise control

Forward collision warning systems

Active brake assist

Lane change assist systems

Traffic jam pilot systems

77 GHz automotive radar modules

Advanced driver assistance systems (ADAS)

Why Choose RO3003G2 for Your Automotive Projects?

RO3003G2 represents more than just another PCB material—it's a solution specifically tailored for the challenges of modern automotive electronics. With its optimized electrical performance, thermal stability, and reliability, RO3003G2 provides the foundation for safety-critical systems that must perform flawlessly in all conditions.

Whether you're developing next-generation radar systems or enhancing existing ADAS platforms, RO3003G2 offers the performance and reliability needed to succeed in the competitive automotive market.