F4BME High Frequency PCBs Deliver Cost-Effective Performance for Commercial RF Systems

September 29, 2025

September 29, 2025

In today's competitive RF and microwave market, achieving optimal performance while maintaining cost efficiency is essential. Wangling's F4BME high-frequency materials offer an exceptional balance of electrical performance, manufacturing flexibility, and value—making them an ideal choice for commercial applications, large-scale production, and cost-sensitive designs.

With a versatile range of dielectric constants and low-loss characteristics, F4BME serves as a reliable domestic alternative to imported high-frequency laminates, without compromising on quality or performance.

What Is F4BME?

F4BME is a PTFE glass fiber cloth copper-clad laminate manufactured using a precise process that combines glass fiber cloth, PTFE resin, and PTFE film. It offers improved electrical performance over standard F4B materials, including a wider range of dielectric constants, lower dielectric loss, and enhanced insulation resistance.

A key differentiator is its use of reversed treated foil (RTF), which provides excellent Passive Intermodulation (PIM) performance, improved line definition, and reduced conductor loss.

Key Features & Benefits

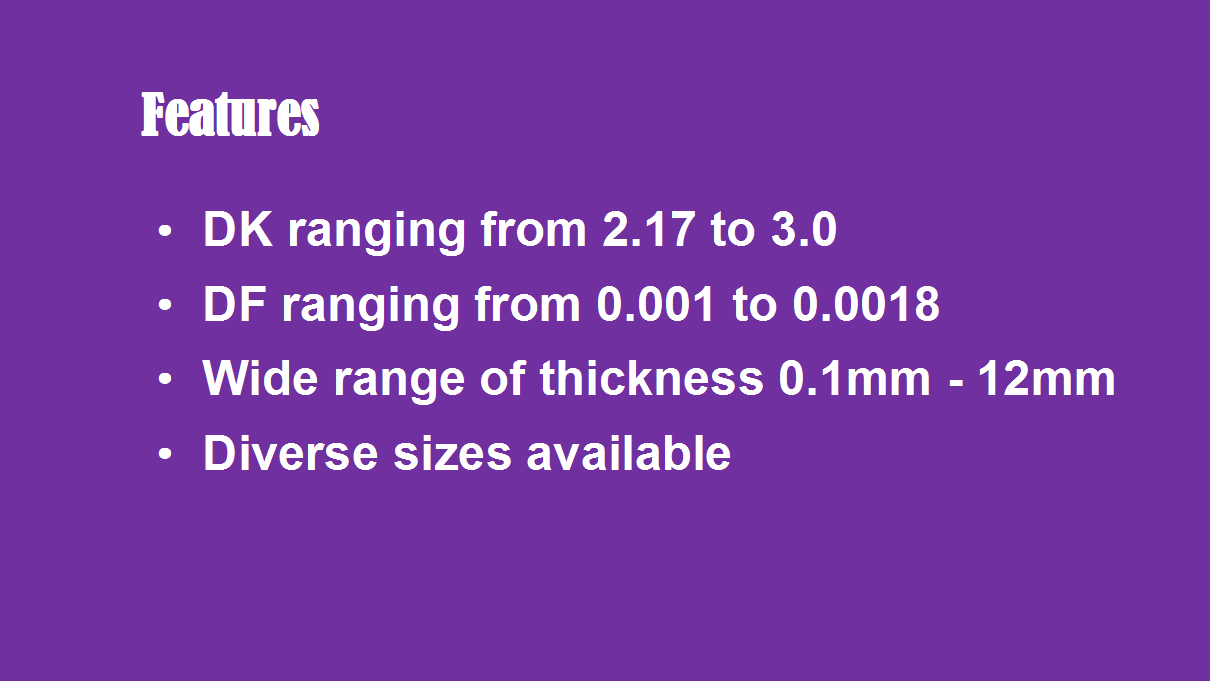

1. Wide Range of Dielectric Constants

Choose from Dk values ranging from 2.17 to 3.0 to match your specific impedance and wavelength requirements.

2.Low Dissipation Factor

With a loss tangent between 0.001 and 0.0018, F4BME ensures minimal signal loss across a broad frequency spectrum.

3.Excellent PIM Performance

The use of RTF copper supports low passive intermodulation, making it suitable for high-frequency and multi-carrier systems.

4.Cost-Effective and Scalable

A wide variety of thicknesses and standard sizes help reduce material waste and lower overall project costs.

5.Stable and Reliable

Enhanced insulation resistance and thermal stability support consistent performance in commercial and industrial environments.

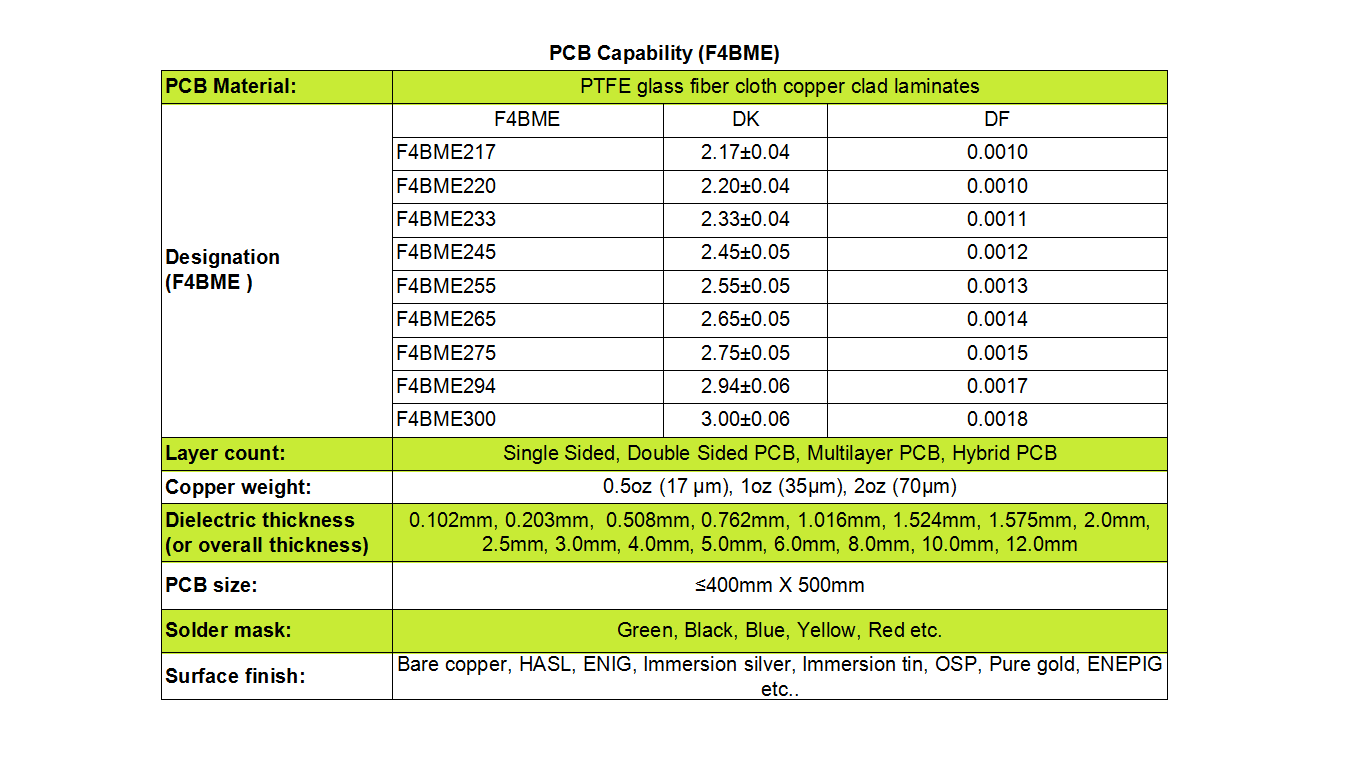

F4BME PCB Capabilities

We support end-to-end manufacturing for F4BME-based circuits, including:

Board Types: Single-sided, double-sided, multilayer, and hybrid PCBs

Copper Weight: 1 oz (35µm) or 2 oz (70µm)

Dielectric Thickness: 0.8mm to 12.0mm (including 1.524mm, 1.575mm, and other values)

Max. Board Size: Up to 400mm × 500mm

Solder Mask Colors: Green, black, blue, yellow, red, and more

Surface Finishes: ENIG, HASL, Immersion Silver, Immersion Tin, ENEPIG, OSP, Bare Copper, and Pure Gold

Application Areas

F4BME is widely used in communication and radar systems, including:

Phase Shifters and Passive Devices

Power Dividers, Couplers, and Combiners

Feed Networks and Phased Array Antennas

Satellite Communication Systems

Base Station Antennas

Radar and Sensing Systems

Why Choose F4BME?

F4BME delivers a compelling mix of performance, versatility, and affordability. Its compatibility with high-volume manufacturing processes and ability to replace imported laminates make it an excellent choice for commercial RF systems, broadcast infrastructure, and aerospace communications.

Interested in using F4BME in your next design?

Contact us for technical data or a competitive quote.