RO3203 High Frequency PCBs Delivering Performance and Value for RF Applications

October 6, 2025

October 6, 2025

In the competitive landscape of high-frequency electronics, achieving a balance of top-tier electrical performance, mechanical robustness, and cost-effectiveness is key. The RO3203 high-frequency laminate is engineered to meet this exact challenge.

As a ceramic-filled, woven fiberglass-reinforced material from the respected RO3000 series, RO3203 offers exceptional stability and extended frequency performance, making it a smart choice for a wide array of demanding RF and microwave designs.

RO3203 at a Glance

RO3203 is a high-frequency circuit material designed to provide:

A stable dielectric constant (Dk) of 3.02

An ultra-low dissipation factor (Df) of 0.0016

Reliable operation in frequency ranges beyond 40 GHz

Its reinforced construction enhances mechanical stability without sacrificing electrical performance, offering an excellent price-to-performance ratio for commercial and industrial applications.

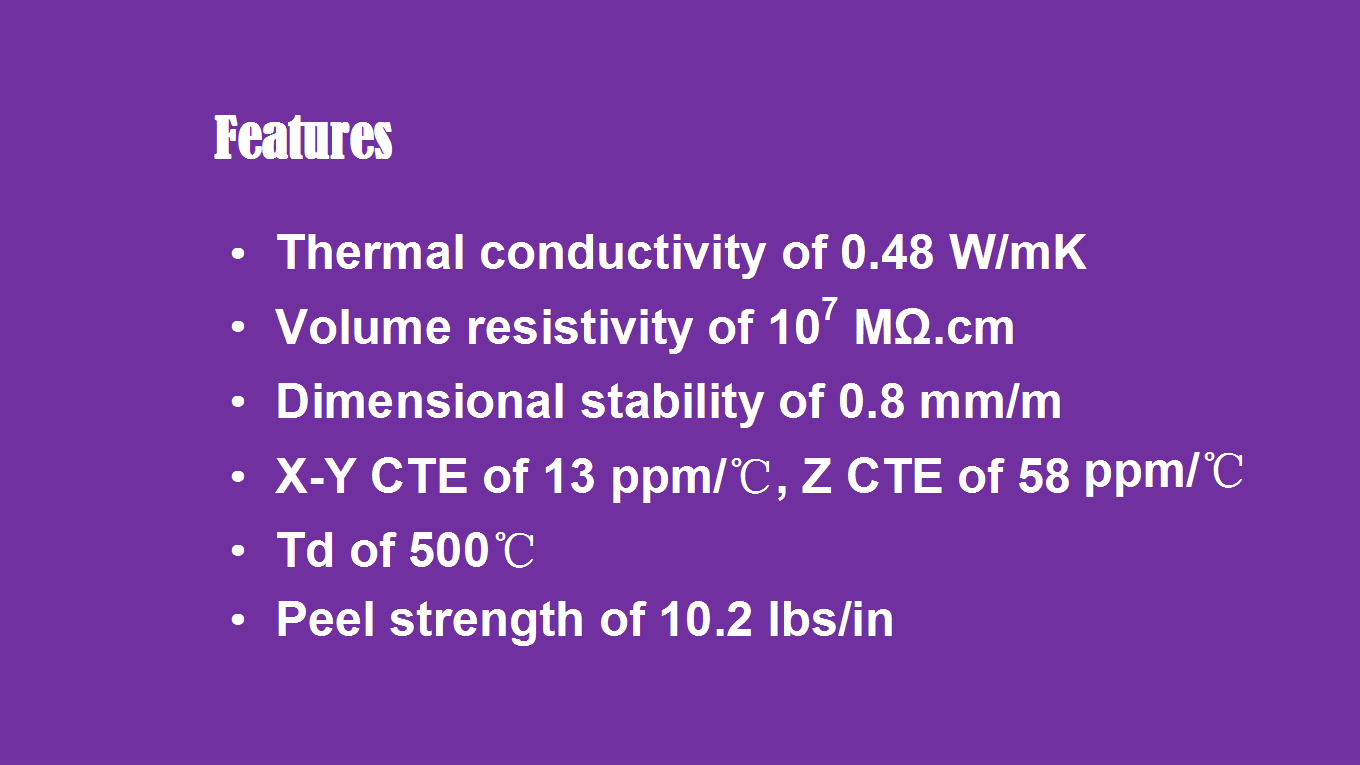

Key Material Properties

Thermal Management: Thermal conductivity of 0.48 W/mK aids in heat dissipation.

Electrical Integrity: High volume and surface resistivity (107 MΩ·cm and 107 MΩ, respectively) ensure reliable insulation.

Dimensional Stability: 0.8 mm/m in X/Y directions supports precision layouts.

Moisture Resistance: Low moisture absorption (<0.1%) maintains performance in humid environments.

Controlled Thermal Expansion: CTE of 13 ppm/°C (X/Y) and 58 ppm/°C (Z) minimizes stress during thermal cycling.

Robust & Reliable:

Thermal decomposition temperature: 500°C

Copper peel strength: 10.2 lbs/in

UL 94 V-0 flammability rating

Lead-free process compatible

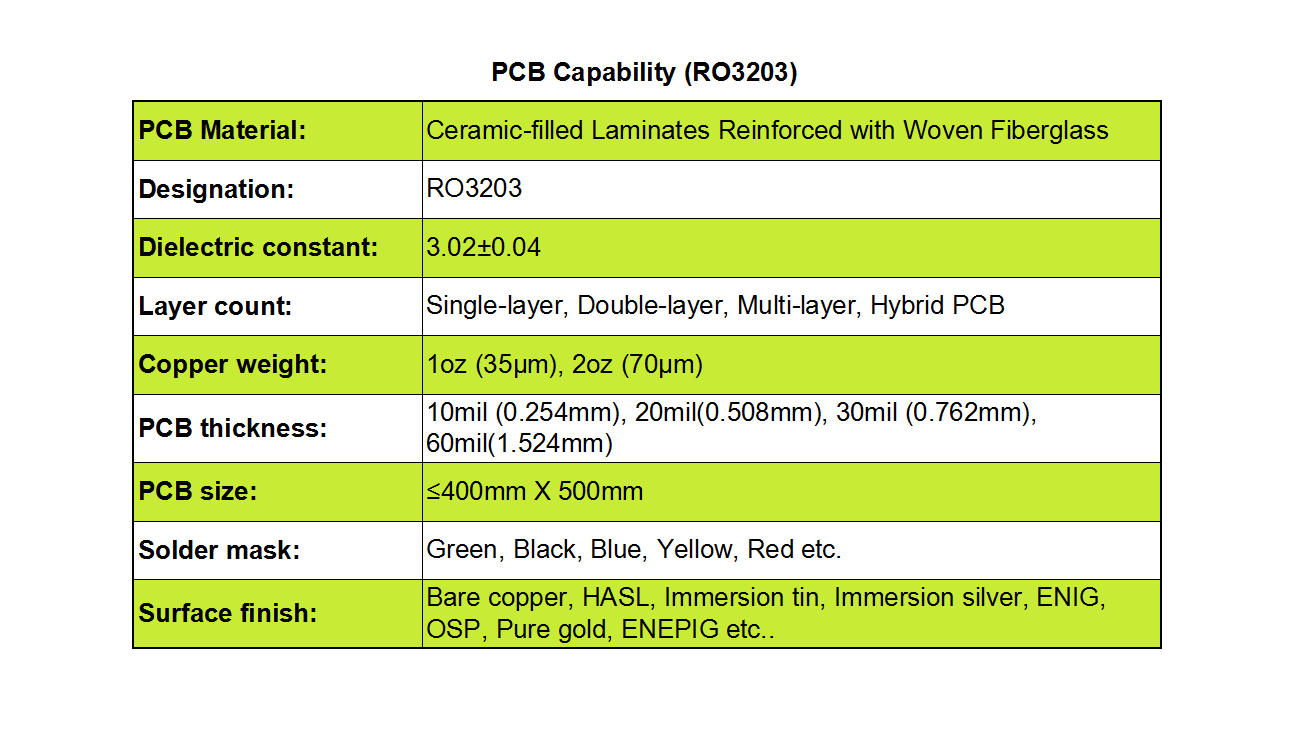

PCB Manufacturing Flexibility

We support a full suite of fabrication options with RO3203:

Stack-Ups: Single-layer, double-layer, multilayer, and hybrid configurations

Copper Weight: 1 oz (35µm) and 2 oz (70µm) standard

Thickness Options: 10 mil, 20 mil, 30 mil, 60 mil, and more

Max Board Size: Up to 400 mm × 500 mm

Solder Mask Colors: Green, black, blue, yellow, red, and others

Surface Finishes: ENIG, HASL, Immersion Silver, OSP, Immersion Tin, ENEPIG, Pure Gold, and bare copper

Common Applications

RO3203 is widely used in cost-sensitive yet performance-driven applications, such as:

Automotive collision avoidance systems

GPS antennas

Microstrip patch antennas

Direct broadcast satellites

Remote meter readers (AMI/AMR systems)

Why Choose RO3203?

Whether you're designing for the automotive sector, satellite communications, or IoT infrastructure, RO3203 provides a dependable, cost-efficient substrate that doesn’t compromise on electrical or mechanical specs.

Its blend of low loss, high-frequency capability, and reinforced stability makes it an ideal solution for engineers targeting reliable, high-volume production.

Interested in integrating RO3203 into your next design? Reach out to explore its potential for your application.