TMS-DS3 High Frequency PCBs Power Demanding RF and Thermal Applications

September 27, 2025

September 27, 2025

In the realm of high-frequency electronics, where signal integrity and thermal management are paramount, TMS-DS3 laminates emerge as a superior substrate solution. Engineered for stability and performance, this material delivers exceptional low-loss characteristics and outstanding thermal properties—making it an ideal choice for challenging RF, microwave, and high-power applications.

From phased array antennas to advanced test equipment, TMS-DS3 provides the reliability and consistency needed in mission-critical systems.

What Is TMS-DS3?

TMS-DS3 is a dimensionally stable, ceramic-filled laminate with minimal fiberglass content (approximately 5%), designed to offer both exceptional electrical performance and ease of fabrication. It combines the processability of epoxy-based materials with the high-frequency capabilities of specialized substrates, supporting everything from complex multilayer boards to large-format designs.

Key Features & Benefits

1. Low Dissipation Factor

With a DF of just 0.0011 at 10 GHz, TMS-DS3 ensures minimal signal loss, making it suitable for sensitive high-frequency applications.

2.Effective Thermal Management

A thermal conductivity of 0.65 W/m·K allows efficient heat dissipation, reducing thermal stress in high-power designs.

3.Improved Thermal Management

Thermal conductivity of 0.85 W/m·K (unclad) supports effective heat dissipation, reducing the risk of thermal-related failures.

4.Excellent Dimensional Stability

Low CTE values across all directions ensure reliability during thermal cycling, protecting plated through-holes and interconnects.

5. Optimized for Multilayer Fabrication

Low fiberglass content and ceramic reinforcement enable reliable performance in complex, large-format multilayer boards.

6. Manufacturing Friendly

Compatible with standard PCB processes, TMS-DS3 simplifies production while maintaining high performance.

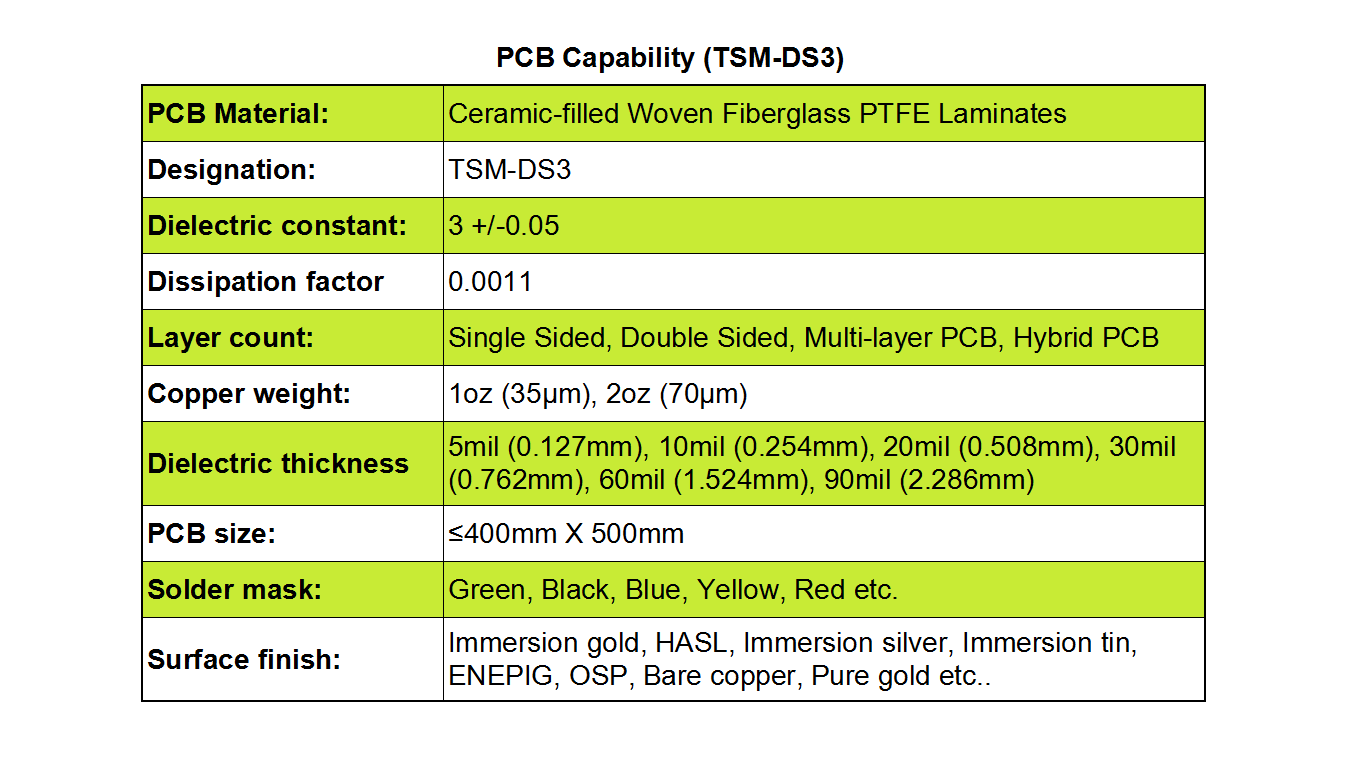

TMS-DS3 PCB Capabilities

We offer comprehensive manufacturing support for TMS-DS3-based designs, including:

Board Construction: Single-sided, double-sided, multilayer, and hybrid configurations

Copper Weight: 1 oz (35µm) or 2 oz (70µm)

Dielectric Thickness: 5 mil to 90 mil (including 10, 20, 30, and 60 mil)

Maximum Dimensions: Up to 400mm × 500mm

Solder Mask Colors: Green, black, blue, yellow, red, and more

Surface Finishes: ENIG, HASL, Immersion Silver, Immersion Tin, ENEPIG, OSP, Bare Copper, and Pure Gold

Application Areas

TMS-DS3 is widely used in advanced electronic systems, including:

RF Couplers and Power Combiners

Phased Array Antennas

Radar Manifolds and Systems

mmWave Antennas

Oil and Gas Drilling Electronics

Semiconductor Test Equipment

Automated Test Systems (ATE)

Design with Confidence Using TMS-DS3

TMS-DS3 offers a unique balance of low-loss performance, thermal resilience, and mechanical stability—making it an excellent substrate for high-frequency and high-power applications. Its versatility and reliability support innovative designs across aerospace, defense, telecommunications, and test engineering.

Interested in integrating TMS-DS3 into your next project? Reach out for technical specifications or a customized quote.