Rogers IsoClad 917 Low-Loss RF PCB for Electronics Design

Brief Introduction

IsoClad 917 is a nonwoven fiberglass reinforced PTFE laminate designed for high-frequency printed circuit board applications. With dielectric constants of 2.17 and 2.20, it offers low loss, high isotropy in all directions, and excellent flexibility, making it ideal for conformal antennas, stripline circuits, and advanced RF electronic systems.

Technical Features

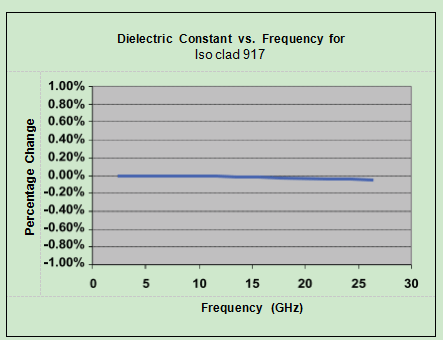

Low Dielectric Constant: Dk = 2.17 or 2.20 at 10 GHz, providing stable signal propagation.

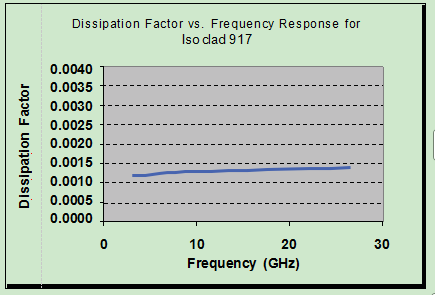

Low Loss Characteristics: Dissipation factor of 0.0013 at 10 GHz, supporting high-frequency performance.

High Isotropic Properties: Uniform mechanical and electrical behavior in X, Y, and Z directions.

Excellent Electrical Insulation: Volume resistivity up to 1.5×10¹⁰ MΩ·cm, surface resistivity up to 1.0×10⁹ MΩ.

Good Thermal Stability: Thermal coefficient of Dk = –157 ppm/°C for reliable operation over temperature ranges.

.jpg)

Typical Properties:

| Property | Test Method | Condition | IsoClad 917 |

|---|---|---|---|

| Dielectric Constant @ 10 GHz | IPC TM-650 2.5.5.5 | C23/50 | 2.17, 2.20 |

| Dissipation Factor @ 10 GHz | IPC TM-650 2.5.5.5 | C23/50 | 0.0013 |

| Thermal Coefficient of Dk | IPC TM-650 2.5.5.5 Adapted | –10°C to +140°C | –157 ppm/°C |

| Peel Strength (lbs/in) | IPC TM-650 2.4.8 | After Thermal Stress | 10 |

| Volume Resistivity (MΩ·cm) | IPC TM-650 2.5.17.1 | C96/35/90 | 1.5×10¹⁰ |

| Surface Resistivity (MΩ) | IPC TM-650 2.5.17.1 | C96/35/90 | 1.0×10⁹ |

| Arc Resistance (seconds) | ASTM D-495 | D48/50 | >180 |

| Tensile Modulus (kpsi) | ASTM D-638 | A, 23°C | 133, 120 |

| Tensile Strength (kpsi) | ASTM D-882 | A, 23°C | 4.3, 3.8 |

| Compressive Modulus (kpsi) | ASTM D-695 | A, 23°C | 182 |

| Flexural Modulus (kpsi) | ASTM D-790 | A, 23°C | 213 |

| Dielectric Breakdown (kV) | ASTM D-149 | D48/50 | >45 |

| Density (g/cm³) | ASTM D-792 Method A | A, 23°C | 2.23 |

| Water Absorption (%) | MIL-S-13949H 3.7.7 / IPC TM-650 2.6.2.2 | E1/105 + D24/23 | 0.04 |

| CTE – X Axis (ppm/°C) | IPC TM-650 2.4.24 (Mettler 3000 TMA) | 0°C to 100°C | 46 |

| CTE – Y Axis (ppm/°C) | IPC TM-650 2.4.24 (Mettler 3000 TMA) | 0°C to 100°C | 47 |

| CTE – Z Axis (ppm/°C) | IPC TM-650 2.4.24 (Mettler 3000 TMA) | 0°C to 100°C | 236 |

| Thermal Conductivity (W/m·K) | ASTM E-1225 | 100°C | 0.263 |

| Outgassing – TML (%) | NASA SP-R-0022A | 125°C, ≤10⁻⁶ torr | 0.02 |

| Outgassing – CVCM (%) | NASA SP-R-0022A | 125°C, ≤10⁻⁶ torr | 0.00 |

| Outgassing – WVR (%) | NASA SP-R-0022A | 125°C, ≤10⁻⁶ torr | 0.02 |

| Visible Condensate | NASA SP-R-0022A | 125°C, ≤10⁻⁶ torr | NO |

| Flammability | UL 94 Vertical Burn / IPC TM-650 2.3.10 | C48/23/50, E24/125 | Meets UL94-V0 |

Application Areas

Conformal Antennas: Where flexibility and isotropic properties are required.

Stripline and Microstrip Circuits: High-frequency PCB designs for communication systems.

Missile Guidance Systems: Reliable performance in demanding aerospace environments.

Radar and Electronic Warfare Systems: Low-loss, high-stability substrates.

RF Test and Measurement: Calibration boards and probe cards.

Why Choose Us?

1. Engineering design prevents problems from occurring in pre-production;

2. ISO9001, ISO14001, ISO13485, UL certified manufacturing factory;

3. AOI inspection;

4. Delivery on time higher than 98% on-time-delivery rate;

5. 16000m2 workshop;

6. 30000m2 output capability per month;

7. 8000 types of PCB's per month;

8. Quick CADCAM checking and free PCB quotation;

9. More than 18+ years of PCB experience;

10. Customer complaint rate: <1%