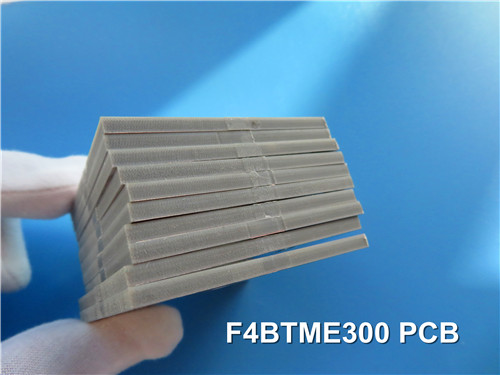

F4BTME300 High Frequency PCB PTFE RF Circuit Board with Immersion Silver

(Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.)

Hello everyone,

Today, we will discuss the F4BTME high frequency circuit board—specifically, the F4BTME300 PCB.

This PCB measures 170 mm x 95 mm and is designed as a double-sided board featuring two layers. It accommodates surface mount components, while through-hole components are not part of this design. The layer stackup includes a top layer with 35 µm (1 oz) copper, starting with 0.5 oz plating, paired with a core material of F4BTME300 that has a thickness of 3.0 mm. The bottom layer also consists of 35 µm (1 oz) copper with plating. This PCB utilizes immersion silver for excellent solderability and protection. Notably, it does not have a solder mask applied, allowing direct access to the copper layers.

PCB Specifications

F4BTME300 High Frequency PCB PTFE RF PCB Built on 3.0mm thick with Immersion Silver |

|

PCB SIZE |

170 x 95mm=1PCS |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

NO |

LAYER STACKUP |

copper ------- 35um(0.5 oz+plate )TOP layer |

F4BTME300 -3.0mm |

|

copper ------- 35um(0.5 oz + plate) BOT Layer |

|

TECHNOLOGY |

|

Minimum Trace and Space: |

7 mil / 7 mil |

Minimum / Maximum Holes: |

0.5 mm / 0.6 mm |

Number of Different Holes: |

5 |

Number of Drill Holes: |

16 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

2 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

F4BTME300 DK 3.0 |

Final foil external: |

1oz |

Final foil internal: |

N/A |

Final height of PCB: |

3.1 mm ±10% |

PLATING AND COATING |

|

Surface Finish |

Immersion silver |

Solder Mask Apply To: |

no |

Solder Mask Color: |

no |

Solder Mask Type: |

no |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

NO |

Colour of Component Legend |

NO |

Manufacturer Name or Logo: |

Marked on the board in a conductor and leged FREE AREA |

VIA |

Non-Plated through hole(PTH), minimum size 0.5mm. |

FLAMIBILITY RATING |

UL 94-V0 Approval MIN. |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

The base color of the F4BTME300 PCB is brown.

F4BTME High Frequency Laminates

The F4BTME series laminates are produced through a meticulous process that involves the scientific formulation of glass fiber cloth, nano-ceramic fillers, and polytetrafluoroethylene (PTFE) resin.

These substrates are built upon the F4BM dielectric layer and incorporate high dielectric constant nano-ceramics, leading to enhanced dielectric performance, superior heat resistance, reduced thermal expansion, increased insulation resistance, and improved thermal conductivity, all while maintaining low loss characteristics.

Additionally, F4BTME laminates are specifically paired with reverse-treated RTF copper foil, providing exceptional performance in terms of phase intermodulation (PIM), precise line control, and minimized conductor loss.

The dielectric constant ranges from 2.98 to 3.5, with ED copper foil available in 0.5 oz, 1 oz, 1.5 oz, and 2 oz options. RTF copper is available in 0.5 oz and 1 oz, with thicknesses ranging from 0.254 mm to 12.0 mm.

Data Sheet (F4BTME300)

Product Technical Parameters |

Product Models & Data Sheet |

||||||

Product Features |

Test Conditions |

Unit |

F4BTME298 |

F4BTME300 |

F4BTME320 |

F4BTME350 |

|

Dielectric Constant (Typical) |

10GHz |

/ |

2.98 |

3.0 |

3.2 |

3.5 |

|

Dielectric Constant Tolerance |

/ |

/ |

±0.06 |

±0.06 |

±0.06 |

±0.07 |

|

Loss Tangent (Typical) |

10GHz |

/ |

0.0018 |

0.0018 |

0.0020 |

0.0025 |

|

20GHz |

/ |

0.0023 |

0.0023 |

0.0026 |

0.0035 |

||

Dielectric Constant Temperature Coefficient |

-55 º~150ºC |

PPM/℃ |

-78 |

-75 |

-75 |

-60 |

|

Peel Strength |

1 OZ F4BTM |

N/mm |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

|

1 OZ F4BTME |

N/mm |

>1.4 |

>1.4 |

>1.4 |

>1.4 |

||

Volume Resistivity |

Standard Condition |

MΩ.cm |

≥1×10^7 |

≥1×10^7 |

≥1×10^7 |

≥1×10^7 |

|

Surface Resistivity |

Standard Condition |

MΩ |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

|

Electrical Strength (Z direction) |

5KW,500V/s |

KV/mm |

>26 |

>30 |

>32 |

>32 |

|

Breakdown Voltage (XY direction) |

5KW,500V/s |

KV |

>34 |

>35 |

>40 |

>40 |

|

Coefficientof Thermal Expansion |

XY direction |

-55 º~288ºC |

ppm/ºC |

15,16 |

15,16 |

13,15 |

10,12 |

Z direction |

-55 º~288ºC |

ppm/ºC |

78 |

72 |

58 |

51 |

|

Thermal Stress |

260℃, 10s,3 times |

No delamination |

No delamination |

No delamination |

No delamination |

||

Water Absorption |

20±2℃, 24 hours |

% |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

|

Density |

Room Temperature |

g/cm3 |

2.25 |

2.25 |

2.20 |

2.20 |

|

Long-Term Operating Temperature |

High-Low Temperature Chamber |

℃ |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

|

Thermal Conductivity |

Z direction |

W/(M.K) |

0.42 |

0.42 |

0.50 |

0.54 |

|

PIM |

Only applicable to F4BTME |

dBc |

≤-160 |

≤-160 |

≤-160 |

≤-160 |

|

Flammability |

/ |

UL-94 |

V-0 |

V-0 |

V-0 |

V-0 |

|

Material Composition |

/ |

/ |

PTFE, Fiberglass Cloth, nano-ceramics |

||||