Flexible Single-Sided FPCs on Polyimide Substrate with 3M and Tesa Tape

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Overview of Our Flexible Single-Sided FPCs

Introducing our state-of-the-art Flexible Printed Circuits (FPCs) designed for versatile applications such as calculator keypads. These single-layer FPCs are crafted with precision, measuring just 0.15mm in thickness, utilizing high-quality Shengyi base laminate. Manufactured in accordance with IPC 6012 Class 2 standards and tailored to your specifications using Gerber data, our FPCs ensure both reliability and performance.

Key Features and Benefits

1.Exceptional Flexibility: Perfect for compact designs that require bending and twisting.

2.Space and Weight Reduction: Lightweight construction helps optimize product design.

3.Consistent Assembly: Streamlined manufacturing leads to higher assembly reliability.

4.Enhanced Reliability: Designed for durability, even in challenging environments.

5.Whole End Soldering Capability: Simplifies installation and enhances connection quality.

6.Cost-Effective Solutions: Competitive pricing without compromising quality.

7.Efficient Processing Continuity: Smooth production flow from start to finish.

8.Experienced Engineering Team: Benefit from over 20 years of industry expertise.

.jpg)

Parameter and data sheet

| Size of Flexible PCB | 30.53 X 59.37mm |

| Number of Layers | 1 |

| Board Type | Flexible PCB |

| Board Thickness | 0.150mm |

| Board Material | Polyimide 25µm |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 60℃ |

| PTH Cu thickness | N/A |

| Inner Iayer Cu thicknes | N/A |

| Surface Cu thickness | 35 µm |

| Coverlay Colour | Yellow |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 µm |

| Stiffener Material | Polyimide |

| Stiffener Thickness | 0.2mm |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 1 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90℃ No peeling after Min. 3 times test |

| Surface Finish | Immersion Gold |

| Thickness of Nickle/Gold | Au: 0.03µm(Min.); Ni 2-4µm |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

.jpg)

Applications

Our flexible circuits are ideal for a variety of applications, including:

Touch screens

LED display soft boards

Tablet antenna soft boards

.jpg)

Adhesive Systems for Optimal Performance

For our flexible circuits, we utilize advanced adhesive systems to bond copper foils to film materials effectively. Two main types of adhesives are employed:

Thermoplastic Adhesives: Suitable for specific processing requirements.

Thermoset Adhesives: Chosen based on application needs.

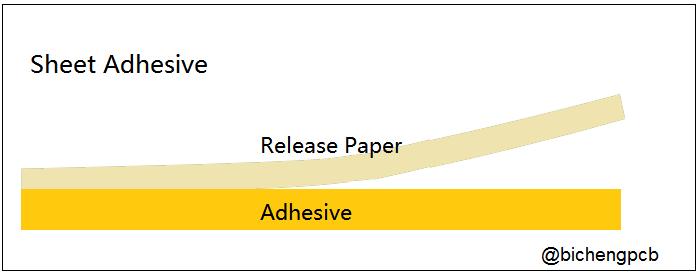

Sheet Adhesives: 3M and Tesa Tape

We use sheet adhesives, primarily low-flow acrylics, applied on polypropylene paper for ease of removal. These adhesives are perfect for bonding flexible circuits into multilayer configurations or attaching stiffeners, ensuring the highest quality connections.

.jpg)