White FPC Flexible Printed Circuit – Dual-Layer Flexible PCB with White Solder Mask on PET for Touch Screens and More

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

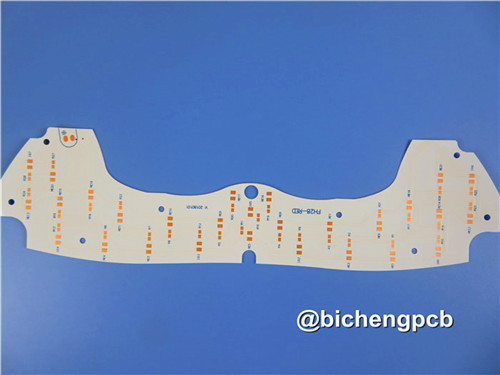

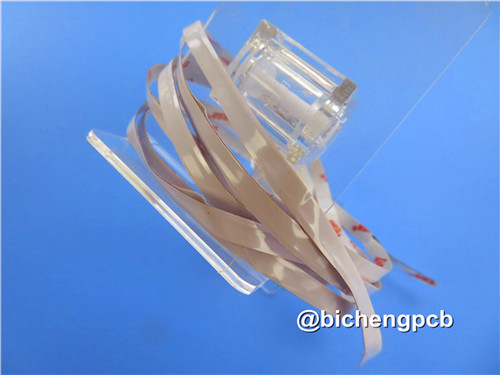

In the realm of flexible electronics, the White FPC Flexible Printed Circuit stands out as a versatile and reliable solution for applications requiring flexibility, durability, and aesthetic appeal. This dual-layer flexible PCB is built on a PET substrate with 1oz copper weight on each layer, coated with a white solder mask and immersion gold on the pads. Designed for printer applications and more, this FPC combines functionality with a sleek, modern design.

Key Features of White FPC Flexible Printed Circuit

1.Excellent Flexibility: The FPC can be bent, folded, and wound, making it ideal for applications where space and flexibility are critical.

2.Reduced Volume and Weight: By using FPC, the overall volume and weight of electronic products can be significantly reduced, enabling the development of smaller and lighter devices.

3.Increased Reliability:The polyimide stiffener provides additional structural support, enhancing the durability and reliability of the circuit.

4.Aesthetic Appeal: The white solder mask not only provides protection but also enhances the visual appeal of the circuit, making it suitable for consumer-facing applications.

5.Low Cost: The FPC offers a cost-effective solution for both prototype and volume production, making it an economical choice for various applications.

6.18+ Years of Experience: With decades of expertise in PCB manufacturing, we deliver high-quality FPCs tailored to your needs.

7.High Customer Satisfaction: Our customer complaint rate is less than 1%, ensuring you receive reliable and high-quality products.

.jpg)

FPC Specifications

| PCB SIZE | 172 x 145mm=1PCS |

| Base Material: | PET |

| Number of Layers | Double sided PCB |

| SMT | n/a |

| Through Hole Components | no |

| LAYER STACKUP | Copper ------- 35um(1oz) |

| Adhesive | |

| PET | |

| Adhesive | |

| Copper ------- 35um(1oz) | |

| Minimum Trace and Space: | 4mil/8mil |

| Minimum / Maximum Holes: | 1.2mm/ 3.5mm |

| Final foil external: | 1oz |

| Final foil internal: | 0oz |

| Final height of PCB: | 0.25mm ±0.05 |

| Surface Finish | Immersion gold |

| Solder Mask Apply To: | TOP, Bottom |

| Solder Mask Color: | White Coverlay |

| CONTOUR/CUTTING | Punching |

| Stiffener: | PET on back of gold finger area |

| Side of Component Legend | NO |

| Colour of Component Legend | NO |

| VIA | Plated Through Hole(PTH) |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

.jpg)

Applications

The White FPC Flexible Printed Circuit is well-suited for a variety of applications, including:

1.Capacitive Touch Screens/Panels: Ideal for touch-sensitive interfaces in consumer and industrial devices.

2.Industrial Control Temperature Controller Soft Boards: Ensures reliable performance in temperature control systems.

3.Consumer Card Reader Soft Boards: Perfect for compact and durable designs in card reader devices.

4.Printer Applications: The bulged pads make it ideal for printer-related applications, ensuring secure connections.

.jpg)

Why Choose White FPC Flexible Printed Circuit?

1.Versatility: The FPC can be used in a wide range of applications, from consumer electronics to industrial devices.

2.Structural Support: The polyimide stiffener provides additional rigidity where needed, ensuring the FPC can withstand mechanical stress.

3.Cost-Effective: The FPC offers a low-cost alternative to traditional rigid PCBs, making it an economical choice for low to medium volume production.

4.High Reliability: Manufactured to IPC 6012 Class 2 standards, the FPC ensures high quality and reliability.

5.Global Availability: Ready to ship worldwide, ensuring timely delivery for your projects.

Covercoat / Solder Mask

In flexible PCBs, the solder mask, often referred to as covercoat, is typically a polyimide film coated with a semi-cured adhesive. This covercoat is laminated to the flexible circuit under heat and pressure, encapsulating the copper pattern while exposing the solder pads through access holes. The covercoat production sheet is cut slightly smaller than the flexible circuit sheet to avoid premature edge sealing, which could trap air bubbles.

For high-volume production, punching is more cost-effective than drilling. However, when drilling, it is necessary to compensate for dimensional changes in the flexible circuit sheet, which can be as much as 0.2%.

Conclusion

The White FPC Flexible Printed Circuit is a high-performance, cost-effective solution designed for applications requiring both flexibility and aesthetic appeal. With its excellent flexibility, increased reliability, and low cost, it is an ideal choice for engineers working on capacitive touch screens, industrial control systems, and consumer electronics.

FPC Capabilities 2025

| No. | Specifications | Capabilities |

| 1 | Board Type | Single layer, Doulbe layer, Multilayer, Rigid-Flex |

| 2 | Base Material | PI, PET |

| 3 | Copper Weight | 0.5oz, 1oz, 2oz |

| 4 | LED Maximum Size | 250 x 5000mm |

| 5 | General Maximum Size | 250 x 2000mm |

| 6 | Board Thickness | 0.03mm-3.0mm |

| 7 | Thickness Tolerance | ±0.03mm |

| 8 | Mininum Drill Hole | 0.05mm |

| 9 | Maximum Drill Hole | 6.5mm |

| 10 | Tolerance of Drill Hole | ±0.025mm |

| 11 | Thickness of Hole Wall | ≧ 8 um |

| 12 | Minimum Track/Gap of Single Layer Board | 0.025/0.03mm |

| 13 | Minimum Track/Gap of Double Layer and Multilayer Board | 0.03/0.040mm |

| 14 | Etching Tolerance | ±0.02mm |

| 15 | Minimum Width of Silk Legend | ≧ 0.125mm |

| 16 | Minimum Heigh of Silk Legend | ≧0.75mm |

| 17 | Distance from Legend to Pad | ≧0.15mm |

| 18 | Distance from Opening Solder Mask of Drill Coverlay to Track | ≧0.03mm |

| 19 | Distance from Opening Solder Mask of Punching Coverlay to Track | ≧0.03mm |

| 20 | Thickness of Immersion Nickel | 100-300u" |

| 21 | Thickness of Immersion Gold | 1-3u" |

| 22 | Thicnkess of Immersion Tin | 150-400u" |

| 23 | Minimum Electrical Testing Pad | 0.2mm |

| 24 | Minimum Tolerance of Outline(Normal Steel Mould Punch) | ±0.1mm |

| 25 | Minimum Tolerance of Outline (Precision Steel Mould Punch) | ±0.05mm |

| 26 | Mininum Radius of Bevel Angle (Outline) | 0.2mm |

| 27 | Stiffner Material | PI, FR-4, 3M Adhesive, PET, Steel Sheet |

| 28 | RoHs | Yes |

| 29 | Solder Mask Colour | Yellow, White, Black, Green |