10-Layer Impedance Controlled Printed Circuit Board

(Custom PCBs are tailored products; the images and specifications provided are for reference only.)

General Description

This is a custom-manufactured 10-layer impedance controlled PCB built on an FR-4 substrate with a Tg of 180°C, designed for signal generator applications. The board is 1.6 mm thick, features a white silkscreen (Taiyo) on a green solder mask (Taiyo), and has immersion gold on the pads. It includes single-end impedance in the inner layers and differential impedance control on the top and bottom layers. The base material is sourced from ITEQ, and the board features HDI with blind vias (from the top to inner layer 3) and buried vias (from inner layer 3 to inner layer 5). All boards are fabricated in accordance with IPC 6012 Class 2 using the supplied Gerber data, with each shipment containing 25 boards.

Features and Advantages

1.High Tg Materials: Excellent thermal reliability and CAF resistance, ensuring long-term reliability for industrial and automotive applications.

2.Gold Pads: Provide good oxidation resistance and efficient heat dissipation.

3.Certifications: Factories are UL, ISO14001, and IATF16949 certified.

4.Delivery Rate: Over 98% on-time delivery rate.

5.Customer Satisfaction: Complaint rate of less than 1%.

6.Order Flexibility: No minimum order quantity; individual pieces are available.

.jpg)

Applications

Modems

Data loggers

Wireless routers

24V transformers

3G USB devices

PLC programming

Embedded development

Master modules

Computers

PCB Data Sheet

| PCB SIZE | 99.1 x 105.3mm=1PCS |

| BOARD TYPE | Multilayer PCB |

| Number of Layers | 10 Layers |

| Surface Mount Components | YES |

| Through Hole Components | YES |

| LAYER STACKUP | copper ------- 17.5um(0.5oz)+plate TOP Signal |

| 4mil prepreg 2113 | |

| copper ------- 35um(1oz) GND Plane | |

| 5mil FR-4 | |

| copper ------- 18um(0.5oz) SIG1 | |

| 5mil prepreg 2116 | |

| copper ------- 18um(0.5oz) SIG2 | |

| 5mil FR-4 | |

| copper ------- 35um(1 oz) PWR Plane | |

| 13mil prepreg 7628 + 1080 | |

| copper ------- 35um(1 oz) GND Plane | |

| 5mil FR-4 | |

| copper ------- 18um(0.5oz) SIG3 | |

| 5mil prepreg 2116 | |

| copper ------- 18um(0.5oz) SIG4 | |

| 5mil FR-4 | |

| copper ------- 35um(1oz) GND Plane | |

| 4mil prepreg 2113 | |

| copper ------- 17.5um(0.5oz)+plate BOT Signal | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 4mil/4mil |

| Minimum / Maximum Holes: | 0.3/5.5mm |

| Number of Different Holes: | 31 |

| Number of Drill Holes: | 3532 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

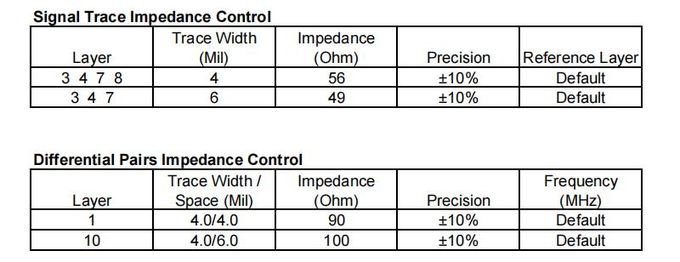

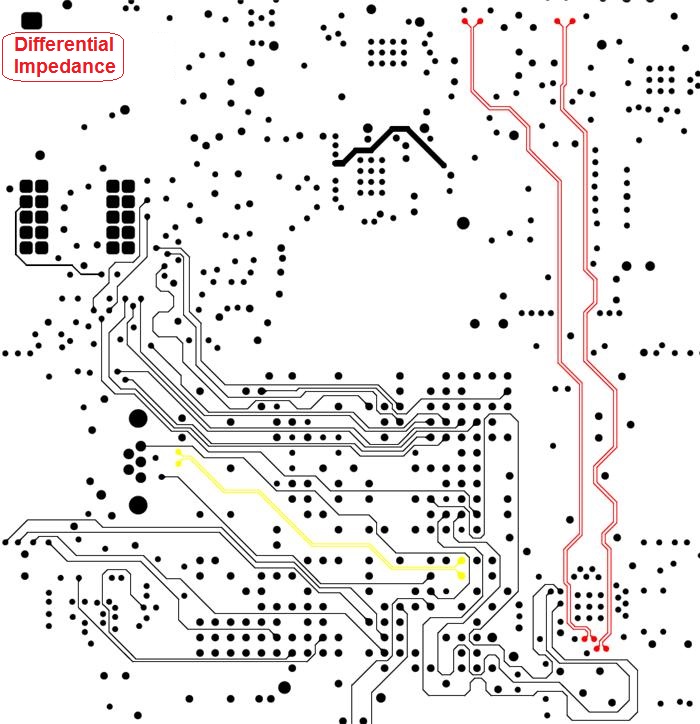

| Impedance Control | Single-Ended Trace Width: L3 / L4 / L7 / L8 --- 4mils --- 56 ohm, L3 / L4 / L 7 --- 6mils --- 49 ohm; Differential impedance: L1 --- 4 mils / 4 mils --- 90 ohm; L10 --- 4 mils / 6 mils --- 100 ohm |

| BOARD MATERIAL | |

| Glass Epoxy: | FR-4, ITEQ IT-180 TG>170, er<5.4 |

| Final foil external: | 1oz |

| Final foil internal: | 0.5oz |

| Final height of PCB: | 1.6mm ±0.16 |

| PLATING AND COATING | |

| Surface Finish | Immersion Gold (12.8%) 2µ" over 100µ" nickel |

| Solder Mask Apply To: | Top and Bottom, 12micon Minimum. |

| Solder Mask Color: | Green, PSR-2000GT600D, Taiyo supplied |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | TOP and Bottom. |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo Supplied. |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | Plated Through Hole(PTH), Blind via (L1-L4), buried via (L4-L6), Via in Pad and via tented and not be visible. |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Single Ended and Differential Impedance

Definition of Characteristic Impedance:

Characteristic impedance is defined as the resistance encountered by high-frequency signals or electromagnetic waves during transmission relative to a reference layer. It is the vector summation of electrical impedance, inductive reactance, and capacitive resistance.

Types of Characteristic Impedance:

1.Single Ended (Line) Impedance: Measured for a single signal line.

2.Differential Impedance: Measured between two transmission lines with equivalent width and spacing in differential drive.

3.Coplanar Impedance: Measured with the signal line transmitting between its surrounding ground (GND) or VCC.

Determinant Conditions for Impedance Control

When signals are transmitted in a PCB conductor, if the conductor length approaches 1/7 of the signal wavelength, it acts as a signal transmission line, necessitating impedance control. The requirement for impedance control during PCB production is based on customer specifications. If a specific line width needs impedance control, it must be managed in production. The three basic elements of impedance matching include:

Output impedance (active components)

Characteristic impedance (signal line)

Input impedance (passive components on the PCB)