Advanced PCB Materials for High-Frequency Applications: RT/Duroid 5880 and RO4003C

(Custom PCBs are tailored products; the images and specifications provided are for reference only.)

Introduction

Rogers RT/Duroid 5880

Rogers RT/Duroid 5880 high-frequency laminates are PTFE composites reinforced with glass microfibers. This material exhibits a low dielectric constant (Dk) and low dielectric loss, making it highly suitable for high-frequency and broadband applications. The randomly oriented microfibers that reinforce the PTFE composites help maintain uniformity in the Dk, ensuring reliable performance in demanding environments.

Rogers RO4003C

Rogers RO4003C materials, on the other hand, are proprietary woven glass reinforced hydrocarbon/ceramics. They combine the electrical performance characteristics of PTFE with woven glass and the manufacturability of epoxy/glass. RO4003C laminates offer precise control over dielectric constant (Dk) and low loss while utilizing the same processing techniques as standard epoxy/glass. This results in a significantly lower cost compared to conventional microwave laminates. Unlike PTFE-based microwave materials, RO4003C does not require special through-hole treatments or handling procedures. Notably, these materials are non-brominated and do not meet the UL 94 V-0 rating.

Features

RT/Duroid 5880

Rogers RT/Duroid 5880 is characterized by:

Dielectric Constant: 2.2 with a tolerance of 0.02 at 10 GHz and 23°C

Dissipation Factor: 0.0009 at 10 GHz

Temperature Coefficient of Dielectric Constant (TCDk): -125 ppm/°C

Low Moisture Absorption: 0.02%

Coefficient of Thermal Expansion (CTE): X-axis: 31 ppm/°C, Y-axis: 48 ppm/°C, Z-axis: 237 ppm/°C

Isotropic Properties

RO4003C

Rogers RO4003C features include:

Dielectric Constant: 3.38 ± 0.05 at 10 GHz

Dissipation Factor: 0.0027 at 10 GHz

Thermal Conductivity: 0.71 W/m/°K

Thermal Coefficient of Dielectric Constant: +40 ppm/°C, ranging from -50°C to 150°C

Matched CTE to Copper: X-axis: 11 ppm/°C, Y-axis: 14 ppm/°C

Low Z-axis CTE: 46 ppm/°C

Glass Transition Temperature (Tg): >280 °C

Low Moisture Absorption: 0.06%

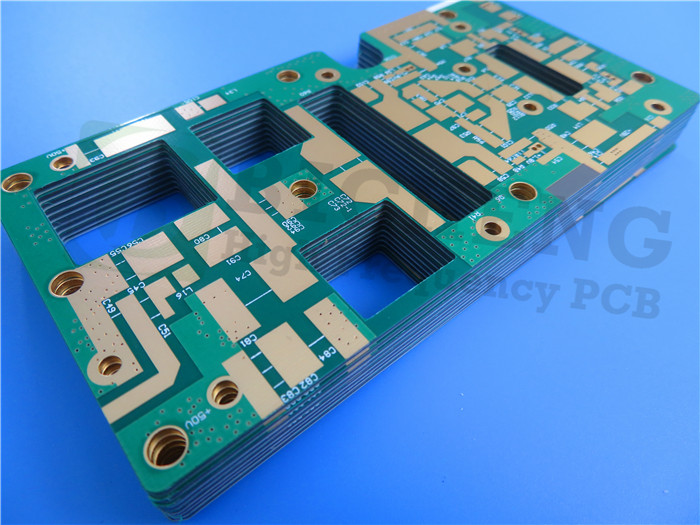

PCB Construction Details

| Parameter | Details |

|---|---|

| Base Material | RT/Duroid 5880 and RO4003C mixed |

| Layer Count | 4 layers |

| Board Dimensions | 110mm x 51mm (± 0.15mm) |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | Top side to Inner layer 1, Inner layer 2 to bottom side |

| Finished Board Thickness | 1.3mm |

| Finished Copper Weight | 1 oz (1.4 mils) for inner/outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | None |

| Top Solder Mask | Green |

| Bottom Solder Mask | None |

| Electrical Testing | 100% electrical test before shipment |

PCB Stackup

Copper Layer 1: 35 μm

RT/Duroid 5880: 0.787 mm (31 mil)

Copper Layer 2: 35 μm

RO4450F Prepreg Bondply: 0.101 mm (4 mil)

Copper Layer 3: 35 μm

RO4003C: 0.203 mm (8 mil)

Copper Layer 4: 35 μm

PCB Statistics

Components: 41

Total Pads: 85

Through Hole Pads: 54

Top SMT Pads: 31

Bottom SMT Pads: 0

Vias: 52

Nets: 5

Standards and Availability

Artwork Type: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide

Typical Applications

Commercial airline broadband antennas

Microstrip and stripline circuits

Millimeter-wave applications

Radar systems

Guidance systems

Point-to-point digital radio antennas

In conclusion, RT/Duroid 5880 and RO4003C are top-tier materials in the PCB industry, delivering high performance for demanding high-frequency applications. Their unique properties ensure reliability and efficiency in advanced electronic designs.