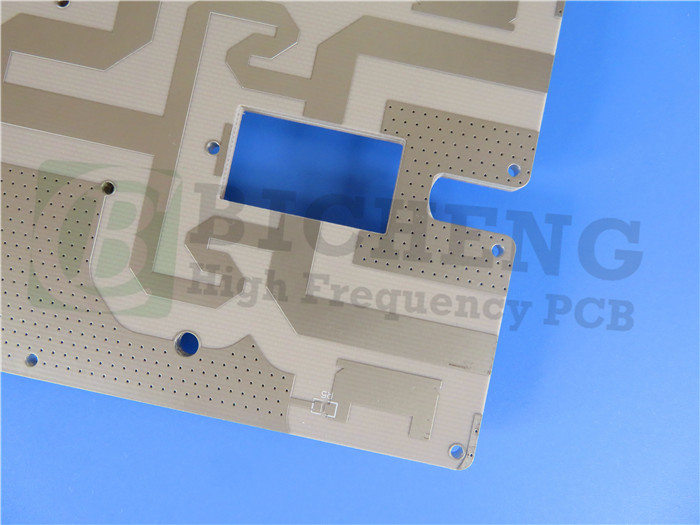

3 Layer Hybrid High Frequency PCB RO3003 RO3210 Material 3mm Thick for Automotive Radar and 5G Applications

(Custom PCBs are tailored products; the images and specifications provided are for reference only.)

Product Overview

RO3210

Rogers' RO3210 high-frequency circuit materials are ceramic-filled laminates reinforced with woven fiberglass, engineered to deliver exceptional electrical performance and superior mechanical stability. A key feature of these materials is their enhanced mechanical properties.

RO3210 laminates offer the smooth surface of non-woven PTFE for precise line etching, combined with the rigidity of woven-glass PTFE laminates. They can be fabricated into printed circuit boards using standard PTFE processing techniques.

RO3003

Rogers RO3003 high-frequency laminates are ceramic-filled PTFE composites designed for commercial microwave and RF applications. These laminates provide excellent stability of dielectric constant (Dk) across a range of temperatures and frequencies, effectively eliminating the typical step change in Dk that occurs near room temperature in PTFE-glass materials. This makes RO3003 ideal for applications such as automotive radar (77 GHz), advanced driver assistance systems (ADAS), and 5G wireless infrastructure (mmWave).

Key Specifications

| Parameter | Specification |

|---|---|

| Base Material | Rogers RO3003 + RO3210 hybrid |

| Layer Count | 3 layers |

| Dimensions | 62.8 × 62.8 mm (±0.15mm) |

| Thickness | 3.0mm |

| Copper Weight | 1oz (35μm) outer layers |

| Trace/Space | 7/9 mils minimum |

| Min Hole Size | 0.4mm |

| Via Technology | Blind vias (L2-bottom) |

| Surface Finish | Immersion Tin |

| Solder Mask | None (both sides) |

| Silkscreen | None (both sides) |

| Quality Standard | IPC-Class 2 |

| Testing | 100% electrical test |

Material Properties

RO3210 Characteristics:

Dielectric Constant: 10.2±0.5

Dissipation Factor: 0.0027 @10GHz

CTE: X=13, Y=13, Z=34 ppm/°C

Thermal Conductivity: 0.81 W/mK

Td: 500°C (TGA)

UL 94 V-0 rated

Excellent mechanical stability

RO3003 Characteristics:

Dielectric Constant: 3.0±0.04 @10GHz/23°C

Dissipation Factor: 0.001 @10GHz/23°C

CTE: X=17, Y=16, Z=25 ppm/°C (-55 to 288°C)

Thermal Conductivity: 0.5 W/mK

Water Absorption: 0.04%

Td: >500°C

PCB Stackup

The 3-layer hybrid construction features:

Top Layer: 35μm Cu

Rogers RO3003 Core: 1.524mm (60mil)

RO4450F Bondply: 0.101mm (4mil)

Middle Layer: 35μm Cu

Rogers RO3210 Core: 1.27mm (50mil)

Bottom Layer: 35μm Cu

PCB Statistics

Components: 21

Total Pads: 47

Thru-hole Pads: 35

SMT Pads: 12 (Top only)

Vias: 24

Nets: 4

Artwork Format: Gerber RS-274-X

Global Availability

Typical Applications

Automotive radar systems (77GHz)

ADAS (Advanced Driver Assistance Systems)

5G wireless infrastructure (mmWave)

GPS satellite antennas

Microstrip patch antennas

Wireless broadband systems

Base station components

Remote monitoring systems

Quality Assurance

IPC-Class 2 compliant

100% electrical testing

Dimensional stability control

Reliable plated through-hole quality

Severe thermal shock resistant