Hybrid PCB - SCGA-500 GF265 High Frequency Material and High Tg FR-4 with Immersion Gold

(Printed Circuit Boards are custom-made products; the images and parameters shown are for reference only.)

General Description

The Hybrid PCB is a 4-layer circuit board combining SCGA-500 GF265 high-frequency material and High Tg FR-4 (Tg 170°C) to deliver exceptional performance for mixed-signal applications. With 1oz copper on each layer and a finished thickness of 1.2mm, this PCB features immersion gold surface finish on the pads and a green solder mask to protect the track patterns. The board is manufactured in compliance with IPC Class II standards, ensuring high reliability and quality. Each board is 100% tested before shipment, and 25 boards are vacuum-packed for secure delivery.

.jpg)

PCB Specifications

| PCB SIZE | 155mm x 100mm=2pcs=2types |

| BOARD TYPE | Hybrid PCB |

| Number of Layers | 4 layers |

| Surface Mount Components | YES |

| Through Hole Components | YES |

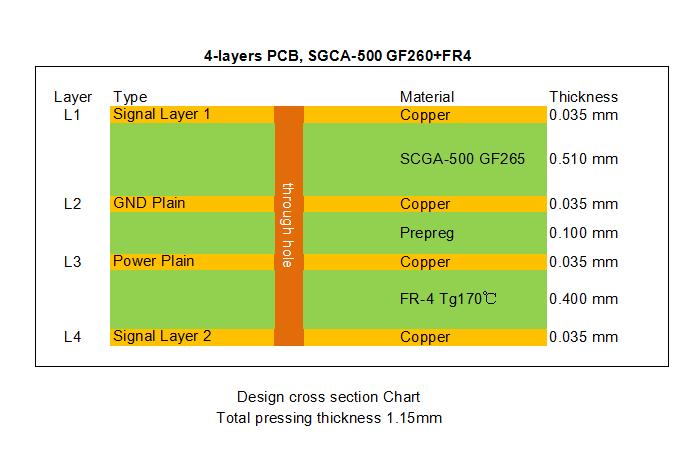

| LAYER STACKUP | copper ------- 17um(0.5 oz)+plate top layer |

| SCGA-500 GF265 0.51mm | |

| copper ------- 35um | |

| Prepreg 0.100mm | |

| copper ------- 35um | |

| FR-4 Tg170℃ | |

| copper ------- 17um(0.5 oz)+plate bottom layer | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 4 mil / 4 mil |

| Minimum / Maximum Holes: | 0.3 mm / 0.9 mm |

| Number of Different Holes: | 6 |

| Number of Drill Holes: | 39 |

| Number of Milled Slots: | 2 |

| Number of Internal Cutouts: | 2 |

| Impedance Control: | no |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Glass Epoxy: | SCGA-500 GF265 + Tg170℃ FR-4 |

| Final foil external: | 1.0 oz |

| Final foil internal: | 1.0 oz |

| Final height of PCB: | 1.2 mm ±0.12 |

| PLATING AND COATING | |

| Surface Finish | Immersion Gold, 78.2% |

| Solder Mask Apply To: | Both sides |

| Solder Mask Color: | Green |

| Solder Mask Type: | Glossy |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | Top side |

| Colour of Component Legend | White |

| Manufacturer Name or Logo: | Kuangshung |

| VIA | Plated through hole(PTH), minimum size 0.3mm. |

| FLAMIBILITY RATING | 94V-0 |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" |

| Board plating: | 0.0029" |

| Drill tolerance: | 0.002" |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Our Advantages

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is a leading high-frequency PCB supplier and exporter based in Shenzhen, China. With over 19 years of experience, we specialize in serving industries such as cellular base station antennas, satellite systems, high-frequency passive components, microstrip and band line circuits, millimeter-wave equipment, radar systems, and digital radio frequency antennas. Our high-frequency PCBs are primarily built on materials from Rogers Corporation, Taconic, and Wangling, with dielectric constants ranging from 2.2 to 10.2.

We also offer a wide range of PCB solutions, including FR-4 circuit boards, flexible circuits, and metal core PCBs, catering to prototypes, small runs, and mass production. Our expertise extends to high-value-added projects such as HDI, quick-turn PCBs, impedance control, heavy copper boards, and backplane boards. This comprehensive product line allows us to meet diverse customer needs, from low-end to high-end applications.

Our PCB Capability (2022)

| Parameter | Value |

| Layer Counts | 1-32 |

| Substrate Materials | RO4350B, RO4003C, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO4835, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/Duroid 6010, RT/duroid 6035HTC; RT/duroid 5880LZ; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5, TLY-5Z; PTFE F4B (DK2.2 DK2.65 DK2.85 DK2.94, DK3.0, DK3.2, DK3.38, DK3.5, DK4.0, DK4.4, DK6.15, DK10.2); AD250C, AD255C, AD300D, AD350A, AD450, AD600, AD1000, TC350; TC600; DiClad 880, DiClad 870, DiClad 527, IsoClad 917; Nelco N4000, N9350, N9240; SCGA-500 GF220, SCGA-500 GF255, SCGA-500 GF265, SCGA-500 GF300; FR-4 ( High Tg S1000-2M, TU-872 SLK, TU-768, IT-180A etc.), FR-4 High CTI>600V; Polyimide, PET; Metal Core etc. |

| Maximum Size | Flying test: 900*600mm, Fixture test 460*380mm, No test 1100*600mm |

| Board Outline Tolerance | ±0.0059" (0.15mm) |

| PCB Thickness | 0.0157" - 0.3937" (0.40mm--10.00mm) |

| Thickness Tolerance(T≥0.8mm) | ±8% |

| Thickness Tolerance(t<0.8mm) | ±10% |

| Insulation Layer Thickness | 0.00295" - 0.1969" (0.075mm--5.00mm) |

| Minimum Track | 0.003" (0.075mm) |

| Minimum Space | 0.003" (0.075mm) |

| Outer Copper Thickness | 35µm--350µm (1oz-10oz) |

| Inner Copper Thickness | 17µm--350µm (0.5oz - 10oz) |

| Drill Hole(Mechanical) | 0.0079" - 0.25" (0.2mm--6.35mm) |

| Finished Hole(Mechanical) | 0.0039"-0.248" (0.10mm--6.30mm) |

| DiameterTolerance(Mechanical) | 0.00295" (0.075mm) |

| Registration (Mechanical) | 0.00197" (0.05mm) |

| Aspect Ratio | 12:1 |

| Solder Mask Type | LPI |

| Min Soldermask Bridge | 0.00315" (0.08mm) |

| Min Soldermask Clearance | 0.00197" (0.05mm) |

| Plug via Diameter | 0.0098" - 0.0236" (0.25mm--0.60mm) |

| Impedance Control Tolerance | ±10% |

| Surface Finish | HASL,HASL LF,ENIG,Immersion Tin,Immersion Silver, OSP, Gold Finger, Pure gold plated etc. |