Kappa 438 High-Frequency PCB – Rogers 20mil 0.508mm DK 4.38 with Immersion Gold Finish

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Revolutionize Your PCB Designs with Rogers Kappa 438 Laminates

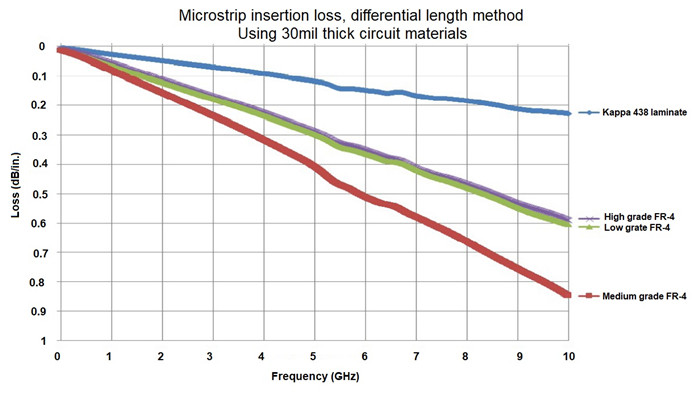

Experience next-level performance with Rogers Kappa 438 laminates, the ultimate solution for high-frequency PCB applications. Designed with a glass-reinforced hydrocarbon ceramic system, these laminates deliver exceptional electrical performance, low signal loss, and cost-effective fabrication. Fully compatible with standard FR-4 processes, Kappa 438 laminates meet UL 94 V-0 flame retardant standards and are optimized for lead-free soldering.

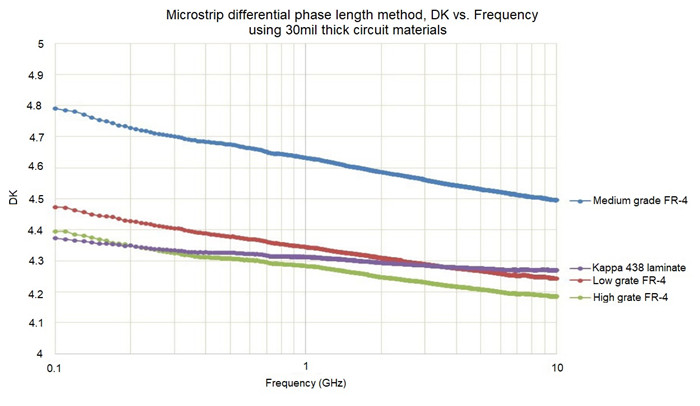

With a dielectric constant (Dk) of 4.38, Kappa 438 laminates align seamlessly with FR-4 industry standards, making it easy to upgrade your existing designs for enhanced performance and reliability.

Why Choose Kappa 438 Laminates?

1.Superior Material Composition: Built on a glass-reinforced hydrocarbon thermoset platform, Kappa 438 offers unmatched durability and performance.

2.Optimized Dielectric Constant (Dk): A Dk of 4.38 ensures consistent signal integrity and minimal signal loss in high-frequency applications.

3.Precision Tolerances: Tighter Dk and thickness tolerances compared to traditional FR-4 materials ensure superior performance in critical applications.

4.3Low Z-Axis CTE: A low coefficient of thermal expansion (42 ppm/°C) ensures stability under thermal stress, reducing the risk of warping or delamination.

5.High Glass Transition Temperature (Tg): With a Tg of >280°C (TMA), Kappa 438 excels in high-temperature environments, making it ideal for demanding applications.

6.Flame Retardant: Meets UL 94-V0 requirements, ensuring safety and compliance in all operating conditions.

Key Benefits of Kappa 438 Laminates

1.Ease of Manufacturing: Simplifies PCB production and assembly, fully compatible with standard FR-4 processes.

2.Design Flexibility: The tailored Dk allows for easy conversion of existing FR-4 designs, enabling enhanced electrical performance without major redesigns.

3.Consistent Performance: Ensures reliable and consistent circuit performance across a wide range of applications.

4.Enhanced Reliability: Improves design flexibility and plated through-hole reliability, ensuring long-term durability.

5.Automation-Friendly: Ideal for automated assembly processes, reducing production time and costs.

Applications of Kappa 438 Laminates

Kappa 438 laminates are perfect for a wide range of high-frequency applications, including:

Carrier-Grade WiFi / Licensed Assisted Access (LAA)

Small Cell and Distributed Antenna Systems (DAS)

Vehicle-to-Vehicle / Vehicle-to-Infrastructure Communications (V2X)

Internet of Things (IoT) Devices

PCB Capability (Kappa 438)

PCB Capability (Kappa 438) |

|

PCB Material: |

Glass Reinforced Hydrocarbon Ceramic |

Designation: |

Kappa 438 |

Dielectric constant: |

4.38 at 2.5GHz |

Layer count: |

Single Layer, Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

1oz (35 µm), 2oz (70µm) |

PCB thickness: |

10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 40mil (1.016mm), 60mil (1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersoin silver, Immersion tin, OSP, ENEPIG, Pure gold etc.. |

Upgrade Your PCB Designs with Kappa 438 Laminates!

Whether you're working on IoT devices, V2X communications, or advanced WiFi systems, Rogers Kappa 438 laminates offer the perfect combination of performance, reliability, and cost efficiency. With low-loss properties, high-temperature stability, and ease of manufacturing, Kappa 438 is the ideal choice for your next high-frequency PCB project.

Kappa 438 Data

Property |

Typical Value Kappa 438 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant, er Design |

4.38 |

Z |

- |

2.5 GHz |

Differential Phase Length Method |

Dissipation Factor tan, d |

0.005 |

Z |

- |

10 GHz/23°C |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of Dielectric Constant e |

-21 |

- |

ppm/°C |

10 GHz (-50 to 150°C) |

Modified IPC-TM-650 2.5.5.5 |

Volume Resistivity |

2.9 x 109 |

- |

MΩ•cm |

COND A |

IPC-TM-650 2.5.17.1 |

Surface Resistivity |

6.2 x 107 |

- |

MΩ |

COND A |

IPC-TM-650 2.5.17.1 |

Electrical Strength |

675 |

Z |

V/mil |

- |

IPC-TM-650 2.5.6.2 |

Tensile Strength |

16 12 |

MD CMD |

kpsi |

- |

ASTM D3039/D3039-14 |

Flexural Strength |

25 19 |

MD CMD |

kpsi |

- |

IPC-TM-650 2.4.4 |

Dimensional Stability |

-0.48-0.59 |

MD CMD |

mm/m |

- |

IPC-TM-650 2.4.39a |

Coefficient of Thermal Expansion |

13 |

X |

ppm/°C |

-55 to 288°C |

IPC-TM-650 2.4.41 |

16 |

Y |

||||

42 |

Z |

||||

Thermal Conductivity |

0.64 |

Z |

W/(m.K) |

80°C |

ASTM D5470 |

Time to Delamination (T288) |

>60 |

- |

minutes |

288°C |

IPC-TM-650 2.4.24.1 |

Tg |

>280 |

- |

°C TMA |

- |

IPC-TM-650 2.4.24.3 |

Td |

414 |

- |

°C |

- |

IPC-TM-650 2.3.40 |

Moisture Absorption |

0.07 |

- |

% |

24/23 |

IPC-TM-650 2.6.2.1 |

Young’s Modulus |

2264 2098 |

MD CMD |

kpsi |

- |

ASTM D3039/D3039-14 |

Flex Modulus |

2337 2123 |

MD CMD |

kpsi |

- |

IPC-TM-650 2.4.4 |

Bow |

0.03 |

- |

% |

- |

IPC-TM-650 2.4.22C |

Twist |

0.08 |

- |

% |

- |

IPC-TM-650 2.4.22C |

Copper Peel Strength After Thermal Stress |

5.8 |

- |

lbs/in |

1 oz (35 µm) foil |

IPC-TM-650 2.4.8 |

Flammability |

V-0 |

- |

- |

- |

UL 94 |

Specific Gravity |

1.99 |

- |

g/cm3 |

- |

ASTM D792 |

Lead-Free Process Compatible |

Yes |

- |

- |

- |

|