Rogers RO3003 6-Layer RF PCB Bonded by FastRise-28 Prepreg for High-Speed Signal Transmission

(Printed Circuit Boards are custom-made products; the images and parameters shown are for reference only)

Introduction

Hello Everyone,

Today, we are discussing a 6-layer RF PCB constructed using Rogers RO3003 materials bonded with FastRise-28 prepreg, specifically designed for high-speed signal transmission.

Material Overview

Rogers RO3003 is a high-frequency circuit material composed of ceramic-filled PTFE composites, ideal for commercial microwave and RF applications. This material offers exceptional electrical and mechanical stability at competitive prices, ensuring consistent mechanical properties. Designers can create multi-layer boards without facing warpage or reliability issues. The coefficient of thermal expansion (CTE) for RO3003 is 17 ppm/°C in the X and Y axes, perfectly matched with copper, which enhances dimensional stability. The Z-axis CTE is 24 ppm/°C, providing exceptional reliability for plated through-holes, even in harsh environments.

Typical Applications

Automotive radar

Cellular telecommunications systems

Datalink on cable systems

Direct broadcast satellites

Global positioning satellite antennas

Patch antennas for wireless communications

Power amplifiers and antennas

Power backplanes

Remote meter readers

Data sheet of RO3003

RO3003 Typical Value |

|||||

Property |

RO3003 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

3.0±0.04 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 Clamped Stripline |

Dielectric Constant,εDesign |

3 |

Z |

|

8GHz to 40 GHz |

Differential Phase Length Method |

Dissipation Factor,tanδ |

0.001 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of ε |

-3 |

Z |

ppm/℃ |

10 GHz -50℃to 150℃ |

IPC-TM-650 2.5.5.5 |

Dimensional Stability |

0.06 |

X |

mm/m |

COND A |

IPC-TM-650 2.2.4 |

Volume Resistivity |

107 |

|

MΩ.cm |

COND A |

IPC 2.5.17.1 |

Surface Resistivity |

107 |

|

MΩ |

COND A |

IPC 2.5.17.1 |

Tensile Modulus |

930 |

X |

MPa |

23℃ |

ASTM D 638 |

Moisture Absorption |

0.04 |

|

% |

D48/50 |

IPC-TM-650 2.6.2.1 |

Specific Heat |

0.9 |

|

j/g/k |

|

Calculated |

Thermal Conductivity |

0.5 |

|

W/M/K |

50℃ |

ASTM D 5470 |

Coefficient of Thermal Expansion |

17 |

X |

ppm/℃ |

23℃/50% RH |

IPC-TM-650 2.4.4.1 |

Td |

500 |

|

℃ TGA |

|

ASTM D 3850 |

Density |

2.1 |

|

gm/cm3 |

23℃ |

ASTM D 792 |

Copper Peel Stength |

12.7 |

|

Ib/in. |

1oz,EDC After Solder Float |

IPC-TM 2.4.8 |

Flammability |

V-0 |

|

|

|

UL 94 |

Lead-free Process Compatible |

Yes |

|

|

|

|

FastRise-28 Prepreg

FastRise-28, a semi-solidified sheet from Taconic, is engineered for high-speed digital signal transmission and millimeter-wave RF multi-layer PCB manufacturing. It pairs well with other Taconic microwave substrate materials to produce multilayer microwave PCBs.

FastRise-28 meets design requirements for stripline structures, offering low dielectric loss. Its thermosetting adhesive properties allow for multiple laminated manufacturing processes. The sheet contains a high proportion of ceramic powder fillers, which enhances dimensional stability. Thanks to its high-performance thermosetting resin, it bonds effectively with copper foil and various PTFE materials.

Key Properties of FastRise-28

FastRise-28 (FR-28) Typical Value |

|||||

Property |

Value |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,ε |

2.78 |

- |

- |

10 GHz |

IPC-TM-650 2.5.5.5.1 |

Dissipation Factor,tanδ |

0.0015 |

- |

- |

10 GHz |

IPC-TM-650 2.5.5.5.1 |

Water Absorption |

0.08 |

|

% |

|

IPC TM-650 2.6.2.1 |

Dielectric breakdown voltage |

49 |

|

KV |

|

IPC TM-650 2.5.6 |

Dielectric strength |

1090 |

|

V/mil |

|

ASTM D 149 |

Volume Resistivity |

8.00 x 108 |

|

MΩ/cm |

|

IPC-TM-650 2.5.17.1 |

Surface Resistivity |

3.48 x 108 |

|

MΩ |

|

IPC-TM-650 2.5.17.1 |

Tg |

188 |

|

℃ |

|

ASTM E 1640 |

Tensil strength |

1690 |

X |

psi |

|

ASTM D 882 |

1480 |

Y |

psi |

|||

Tensil modulus |

304 |

X |

psi |

|

ASTM D 882 |

295 |

Y |

psi |

|||

Density |

1.82 |

|

gm/cm³ |

|

ASTM D-792 Method A |

Td |

709 |

|

°F |

|

IPC TM-650 2.4.24.6 |

Peel Strength |

7 |

|

lbs/in |

|

IPC-TM-650 2.4.8 |

Thermal Conductivity |

0.25 |

|

W/mk |

|

ASTM F433 |

Coefficient of Thermal Expansion |

59 |

X |

ppm/℃ |

|

IPC-TM-650 2.4.41 |

Hardness |

68 |

|

Shore D |

|

ASTM D 2240 |

More FastRise Prepregs

fastRise Prepreg |

|

|||||||

Product |

Carrier film (mil) |

Film Elognation (%) |

Pressed Thickness (mil) |

Pressed Thickness (mil) |

Pressed Thickness (mil) |

Nominal DK (Min. / Max.) (10 GHz) |

Typical Flow (%) |

|

FR-26-0025-60 |

1 |

200-300 |

2.7 |

1.3 |

1 |

2.58 |

17 |

|

FR-27-0030-25 |

2.3 |

30-60 |

3.5 |

2.1 |

Not recommended |

2.74 (2.71 / 2.78) |

4 |

|

FR-27-0035-66 |

1 |

200-300 |

3.7 |

2.5 |

2.1 |

2.7 |

36 |

|

FR-27-0040-25 |

3 |

30-60 |

4.9 |

3.7 |

Not recommended |

2.74 |

4 |

|

FR-28-0040-50 |

1 |

200-300 |

4.9 |

3.7 |

3.5 |

2.81 (2.80 / 2.82) |

23 |

|

FR-27-0042-75 |

2.3 |

30-60 |

5.16 |

3.96 |

3.5 |

2.73 |

35 |

|

FR-27-0045-35 |

3 |

30-60 |

5.8 |

4.6 |

4.2 |

2.75 (2.73 / 2.77) |

13 |

|

FR-27-0050-40 |

3 |

30-60 |

6.1 |

5.5 |

4.9 |

2.76 (2.71 / 2.80) |

23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 oz Cu. 50% removal |

1 oz. Cu. 50% removal |

|

|

|

|

|

|

|

|

|

|

|

|

Storage Recommendations

FastRise is a non-reinforced prepreg, manufactured between release liners to prevent individual plies from sticking together. The adhesive layer on the PTFE/ceramic film can be particularly tacky, especially for freshly produced material. It is advisable to refrigerate FastRise before lamination. Continuous refrigeration is recommended to extend shelf life. Ideally, maintain a temperature close to 4°C to ensure ease of separation from the release liners.

Lamination Process

Various laminate cores can be used with FastRise prepreg to create multilayer boards for RF, digital, and ATE markets. When used in a symmetrical board design, FastRise ensures optimal electrical and mechanical performance. Its thermoset properties allow for multiple bonding cycles without the risk of delamination. The recommended pressing temperature of 215.5°C is achievable for most board houses.

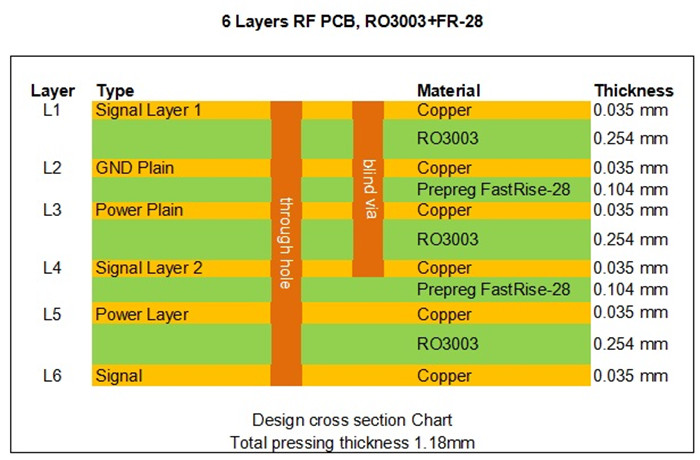

Product Specifications

This RF PCB, built on a Rogers RO3003 core bonded with FastRise-28, features a 6-layer stack-up with 1 oz copper on each layer. The finished board thickness is 1.2 mm, with immersion gold plating on pads. It includes 2+N+2 blind vias from layer 1 to layer 4. See the stack-up below:

Thank you for your attention. For further inquiries regarding our RF PCBs, please feel free to reach out!