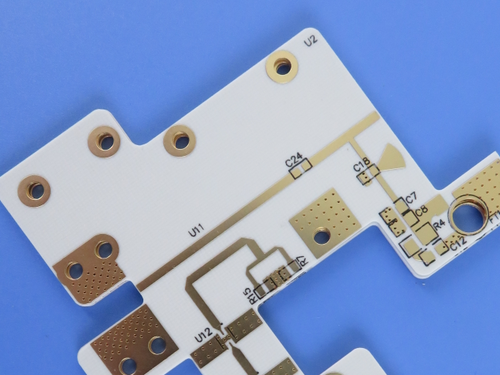

High-Performance RO4360G2 2-Layer PCB for Telecommunications and Power Applications

1. Introduction to RO4360G2

The RO4360G2 laminate is a low-loss, glass-reinforced, hydrocarbon ceramic-filled thermoset material that offers an optimal balance of performance and processing capability. As the first high dielectric constant (Dk) thermoset laminate that can be processed similarly to conventional FR-4, RO4360G2 provides enhanced rigidity for improved processability in multi-layer board constructions. This material is lead-free process capable and helps reduce both material and fabrication costs. It can be effectively paired with RO440 series prepreg and lower-Dk RO4000 laminates in multi-layer designs.

2. Features and Benefits

Features

Dielectric Constant: 6.15 ± 0.15 at 10 GHz and 23°C.

Dissipation Factor: 0.0038 at 10 GHz and 23°C.

Thermal Properties: Td > 407°C; high Tg greater than 280°C (TMA).

Thermal Conductivity: High at 0.75 W/mK.

Low Z-axis CTE: 28 ppm/°C.

Copper-Matched CTE: X-axis: 13 ppm/°C, Y-axis: 14 ppm/°C.

Lead-Free Process Compatibility: 94V-0 flammability rating.

Benefits

Design Flexibility: Allows for versatile applications in various circuit designs.

Plated Through-Hole Reliability: Ensures dependable connections.

Automated Assembly Compatibility: Facilitates efficient manufacturing processes.

Environmentally Friendly: Fully compatible with lead-free processes.

Cost-Effective: Efficient supply chain and short lead times reduce overall material costs.

3. PCB Construction Details

| Base Material | RO4360G2 |

| Layer Count | 2 layers |

| Board Dimensions | 76.32 mm x 67.51 mm (1 piece) |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.20 mm |

| Blind Vias | None |

| Finished Board Thickness | 0.3 mm |

| Finished Copper Weight | 1 oz (1.4 mils) on outer layers |

| Via Plating Thickness | 20 µm |

| Surface Finish | Electroless Nickel Immersion Gold (ENIG) |

| Top Silkscreen | None |

| Bottom Silkscreen | None |

| Top Solder Mask | None |

| Bottom Solder Mask | None |

| Electrical Testing | 100% electrical test conducted prior to shipment |

4. PCB Stackup

Copper Layer 1: 35 µm

RO4360G2 Substrate: 8 mil (0.203 mm)

Copper Layer 2: 35 µm

5.PCB Statistics

Components: 18

Total Pads: 57

Thru Hole Pads: 39

Top SMT Pads: 18

Bottom SMT Pads: 0

Vias: 51

Nets: 2

6.Manufacturing & Compliance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2 compliant

Availability: Worldwide production and shipping

7.Typical Applications

Base station power amplifiers

Small cell transceivers