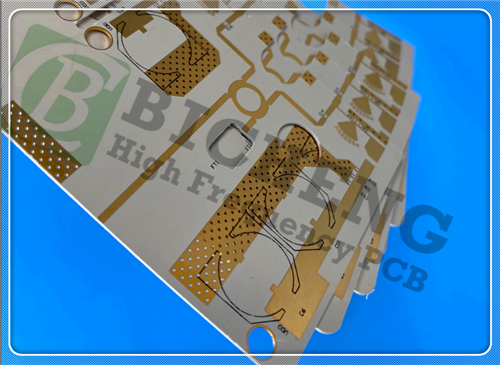

IsoClad 933 PCB 2-Layer 31mil High-Frequency PTFE Laminates for Conformal Antennas and Radar Systems

1. Introduction of IsoClad 933

Rogers IsoClad 933 laminates are non-woven fiberglass/PTFE composites designed for use as PCB substrates. The non-woven reinforcement makes these laminates suitable for applications where the final circuit requires conformability. IsoClad 933 laminates utilize longer random fibers and a proprietary manufacturing process to achieve excellent dimensional stability and enhanced mechanical strength.

2.Features

Dielectric Constant (DK) of 2.33 at 10 GHz/23°C

Dissipation Factor of 0.0016 at 10 GHz/23°C

Strong Peel Strength of 10 lbs per inch

Low water absorption at 0.05%

Low outgassing with 0.03% TML, 0 CVCM, and 0.02% WVR

Excellent Dk uniformity

3. Benefits

Less rigid compared to woven fiberglass

Highly isotropic in the X, Y, and Z axes

Stable dielectric constant across a range of frequencies

Enhanced dimensional stability

4. PCB Stackup: 2-Layer Rigid PCB

Copper Layer 1: 35 µm

Rogers IsoClad 933 Core: 0.787 mm (31 mil)

Copper Layer 2: 35 µm

5. PCB Construction Details

| Specification | Details |

|---|---|

| Board Dimensions | 70.07 mm x 58.31 mm = 1 piece, +/- 0.15 mm |

| Minimum Trace/Space | 5/4 mils |

| Minimum Hole Size | 0.3 mm |

| Blind Vias | No |

| Finished Board Thickness | 0.9 mm |

| Finished Copper Weight | 1 oz (1.4 mils) for outer layers |

| Via Plating Thickness | 20 µm |

| Surface Finish | Immersion Tin |

| Top Silkscreen | White |

| Bottom Silkscreen | None |

| Top Solder Mask | Blue |

| Bottom Solder Mask | None |

| Electrical Testing | 100% testing conducted prior to shipment |

6. PCB Statistics

Components: 19

Total Pads: 52

Through Hole Pads: 25

Top SMT Pads:27

Bottom SMT Pads: 0

Vias: 17

Nets: 2

7. Type of Artwork Supplied

Gerber RS-274-X

8. Accepted Standard

IPC-Class-2

9. Availability

Worldwide

10. Typical Applications

Conformal Antennas

Stripline and Microstrip Circuits

Guidance Systems

Radar and Electronic Warfare Systems