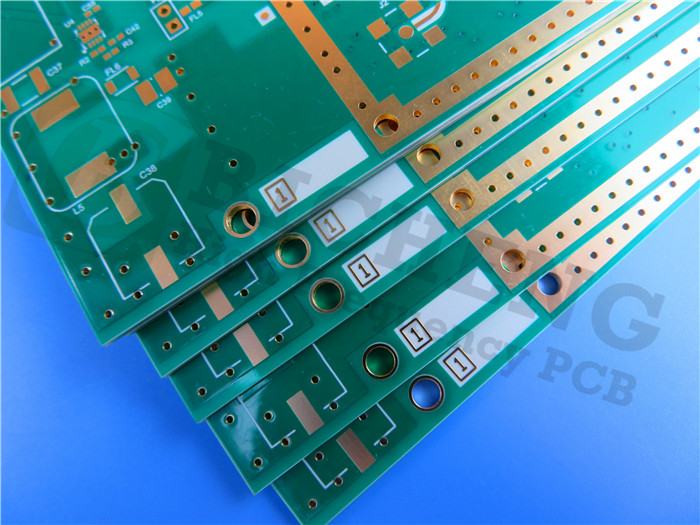

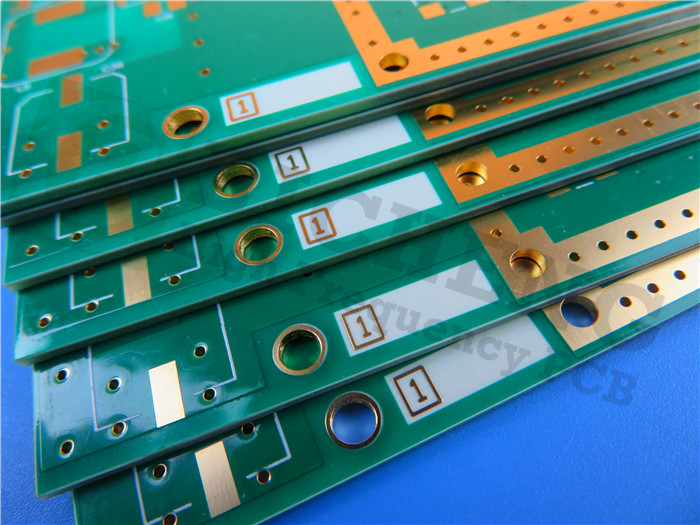

RO4003C LoPro RF PCB Rogers 60.7mil Circuit Board With Immersion Gold for Power Amplifiers

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Product Description

RO4003C LoPro laminates utilize proprietary technology from Rogers that enables reverse treated foil to bond effectively with standard RO4003C dielectric. This results in a laminate characterized by low conductor loss, improving insertion loss and signal integrity while maintaining all the desirable attributes of the standard RO4003C laminate system.

Features and Benefits

RO4003C materials consist of reinforced hydrocarbon/ceramic laminates featuring very low profile reverse treated foil, providing several advantages:

Lower Insertion Loss:Enhances signal transmission efficiency.

Low Passive Intermodulation (PIM):Improves overall performance in RF applications.

Increased Signal Integrity:Ensures clearer and more reliable signal transmission.

High Circuit Density:Supports complex circuit designs without compromising performance.

Thermal and Design Characteristics

Low Z-axis Coefficient of Thermal Expansion:Facilitates multi-layer board capability and design flexibility.

Lead-Free Process Compatible:Supports high-temperature processing and complies with environmental regulations.

CAF Resistant:Enhances reliability in challenging environments.

Typical Applications

1.Digital applications such as servers, routers, and high-speed backplanes

2.Cellular base station antennas and power amplifiers

3.LNBs for direct broadcast satellites

4.RF Identification Tags

PCB Capability (RO4003C LoPro))

Our PCB Capability (RO4003C LoPro) |

|

PCB Material: |

Hydrocarbon Ceramic Laminates |

Designation: |

RO4003C LoPro |

Dielectric constant: |

3.38±0.05 |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness: |

12.7mil (0.323mm), 16.7mil (0.424mm), 20.7mil(0.526mm), 32.7mil (0.831mm), 60.7mil(1.542mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP, Immersion tin etc.. |

Typical Properties of RO4003C LoPro

RO4003C LoPro |

|||||

Property |

Typical Value |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant, Process |

3.38 ± 0.05 |

z |

-- |

10 GHz/23°C |

IPC-TM-650 2.5.5.5 Clamped Stripline |

Dielectric Constant, Design |

3.5 |

z |

-- |

8 to 40 GHz |

Differential Phase Length Method |

Dissipation Factor tan, d |

0.0027 0.0021 |

z |

-- |

10 GHz/23°C 2.5 GHz/23°C |

IPC-TM-650 2.5.5.5 |

Thermal Coeffifi cient of er |

40 |

z |

ppm/°C |

-50°C to 150°C |

IPC-TM-650 2.5.5.5 |

Volume Resistivity |

1.7 X 1010 |

|

MΩ•cm |

COND A |

IPC-TM-650 2.5.17.1 |

Surface Resistivity |

4.2 X 109 |

|

MΩ |

COND A |

IPC-TM-650 2.5.17.1 |

Electrical Strength |

31.2(780) |

z |

KV/mm(V/mil) |

0.51mm(0.020”) |

IPC-TM-650 2.5.6.2 |

Tensile Modulus |

26889(3900) |

Y |

MPa(kpsi) |

RT |

ASTM D638 |

Tensile Strength |

141(20.4) |

Y |

MPa(kpsi) |

RT |

ASTM D638 |

Flexural Strength |

276(40) |

|

MPa(kpsi) |

|

IPC-TM-650 2.4.4 |

Dimensional Stability |

<0.3 |

X,Y |

mm/m(mils/inch) |

after etch +E2/150°C |

IPC-TM-650 2.4.39A |

Coeffifi cient of Thermal Expansion |

11 |

x |

ppm/°C |

-55 to 288°C |

IPC-TM-650 2.1.41 |

14 |

y |

||||

46 |

z |

||||

Tg |

>280 |

|

°C TMA |

A |

IPC-TM-650 2.4.24.3 |

Td |

425 |

|

°C TGA |

|

ASTM D3850 |

Thermal Conductivity |

0.64 |

|

W/m/°K |

80°C |

ASTM C518 |

Moisture Absorption |

0.06 |

|

% |

48 hrs immersion 0.060” sample Temperature 50°C |

ASTM D570 |

Density |

1.79 |

|

gm/cm3 |

23°C |

ASTM D792 |

Copper Peel Strength |

1.05(6.0) |

|

N/mm(pli) |

after solder float 1 oz. TC Foil |

IPC-TM-650 2.4.8 |

Flammability |

N/A |

|

|

|

UL 94 |

Lead-Free Process Compatible |

Yes |

|

|

|

|