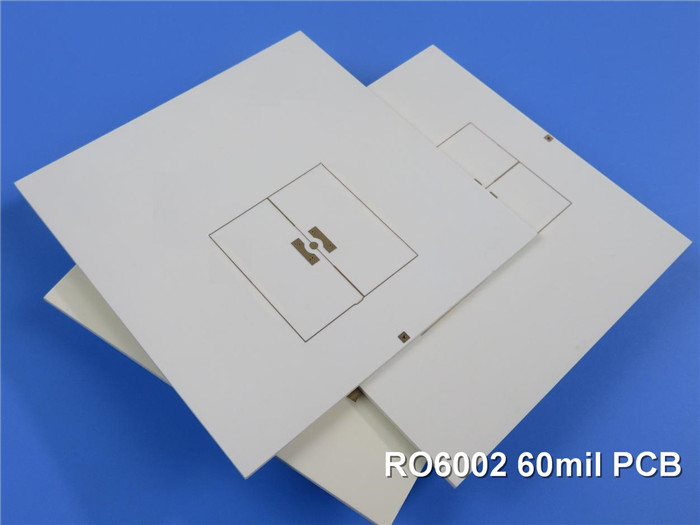

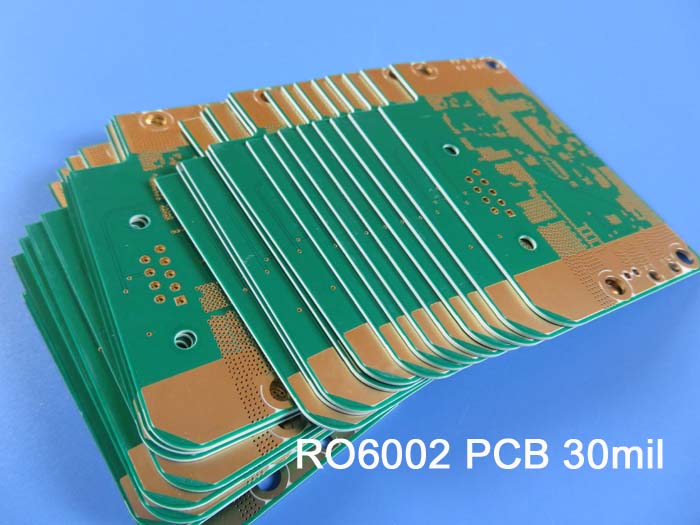

Rogers RT/Duroid 6002 60mil 1.524mm DK2.94 with Immersion Gold for Commercial Airline Collision Avoidance

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Rogers HF PCB built on RT/Duroid 6002 with a thickness of 60mil (1.524mm) and a dielectric constant (DK) of 2.94, features immersion gold finishing, specifically designed for commercial airline collision avoidance systems.

Key Characteristics

1.Low Loss and Dielectric Constant:RT/Duroid 6002 offers superior electrical and mechanical properties, essential for complex microwave structures that require reliability and stability.

2.Thermal Stability:The thermal coefficient of dielectric constant remains stable from -55℃ to +150℃, providing essential electrical stability for filters, oscillators, and delay lines under demanding conditions.

3.Reliable Plated Through Holes:A low Z-axis coefficient of thermal expansion (CTE) ensures excellent reliability, with over 5000 temperature cycles (-55℃ to 125℃) completed without any via failures.

4.Dimensional Stability:Achieves exceptional dimensional stability (0.2 to 0.5 mils/inch) by matching the expansion coefficients of the laminate and copper, often eliminating the need for double etching.

5.Reduced Stress on Solder Joints:The low tensile modulus minimizes stress on solder joints, enhancing surface mount reliability by constraining the laminate's expansion with low CTE metal (6 ppm/℃).

Applications

Applications particularly suited to the unique properties of RT/duroid 6002 material include flat and non-planar structures such antennas, complex mutli-layer circuits with inter-layer connections, and microwave circuits for aerospace designs in hostile environments.

RT/Duroid 6002 is particularly suited for:

*Airborne radar systems

*Beam forming networks

*Commercial airline collision avoidance

*GPS antennas

*Ground-based systems

*High-reliability multi-layer circuits

*Phased array antennas

*Power backplanes

PCB Applications

The unique properties of RT/Duroid 6002 make it ideal for various applications, including flat and non-planar structures, antennas, complex multi-layer circuits with inter-layer connections, and microwave circuits designed for aerospace applications in challenging environments.

Typical Applications Include:

1.Airborne Radar Systems

2.Beam Forming Networks

3.Commercial Airline Collision Avoidance Systems

4.Global Positioning System (GPS) Antennas

5.Ground-Based Systems

6.High-Reliability Complex Multi-Layer Circuits

7.Phased Array Antennas

8.Power Backplanes

PCB Specifications

Rogers RT/Duroid 6002 60mil 1.524mm High Frequency PCB for Commercial Airline Collision Avoidance |

|

PCB SIZE |

99 x 99 mm=1PCS |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

NO |

LAYER STACKUP |

copper ------- 18um(0.5 oz)+plate TOP layer |

RT/duroid 1.524mm |

|

copper ------- 18um(0.5 oz)+plate BOT layer |

|

TECHNOLOGY |

|

Minimum Trace and Space: |

4 mil / 4 mil |

Minimum / Maximum Holes: |

0.3 mm / 2.0mm |

Number of Different Holes: |

1 |

Number of Drill Holes: |

3 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

RT/duroid 1.524mm |

Final foil external: |

1 oz |

Final foil internal: |

1 oz |

Final height of PCB: |

1.6 mm ±0.16 |

PLATING AND COATING |

|

Surface Finish |

Immersion gold (51.3% ) 0.05µm over 3µm nickel |

Solder Mask Apply To: |

NO |

Solder Mask Color: |

NO |

Solder Mask Type: |

NO |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

NO |

Colour of Component Legend |

NO |

Manufacturer Name or Logo: |

NO |

VIA |

Plated through hole(PTH), minimum size 0.3mm. |

FLAMIBILITY RATING |

UL 94-V0 Approval MIN. |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

Data Sheet of Rogers 6002 (RT/Duroid 6002)

RT/duroid 6002 Typical Value |

|||||

Property |

RT/duroid 6002 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

2.94±0.04 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Dielectric Constant,εDesign |

2.94 |

|

|

8GHz to 40 GHz |

Differential Phase Length Method |

Dissipation Factor,tanδ |

0.0012 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of ε |

+12 |

Z |

ppm/℃ |

10 GHz 0℃-100℃ |

IPC-TM-650 2.5.5.5 |

Volume Resistivity |

106 |

Z |

Mohm.cm |

A |

ASTM D 257 |

Surface Resistivity |

107 |

Z |

Mohm |

A |

ASTM D 257 |

Tensile Modulus |

828(120) |

X,Y |

MPa(kpsi) |

23℃ |

ASTM D 638 |

Ultimate Stress |

6.9(1.0) |

X,Y |

MPa(kpsi) |

||

Ultimate Strain |

7.3 |

X,Y |

% |

||

Compressive Modulus |

2482(360) |

Z |

MPa(kpsi) |

|

ASTM D 638 |

Moisture Absorption |

0.02 |

|

% |

D48/50 |

IPC-TM-650 2.6.2.1 |

Thermal Conductivity |

0.6 |

|

W/m/k |

80℃ |

ASTM C518 |

Coefficient of Thermal Expansion |

16 |

X |

ppm/℃ |

23℃/50% RH |

IPC-TM-650 2.4.41 |

Td |

500 |

|

℃ TGA |

|

ASTM D 3850 |

Density |

2.1 |

|

gm/cm3 |

|

ASTM D 792 |

Specific Heat |

0.93(0.22) |

|

j/g/k |

|

Calculated |

Copper Peel |

8.9(1.6) |

|

Ibs/in.(N/mm) |

|

IPC-TM-650 2.4.8 |

Flammability |

V-0 |

|

|

|

UL 94 |

Lead-free Process Compatible |

Yes |

|

|

|

|