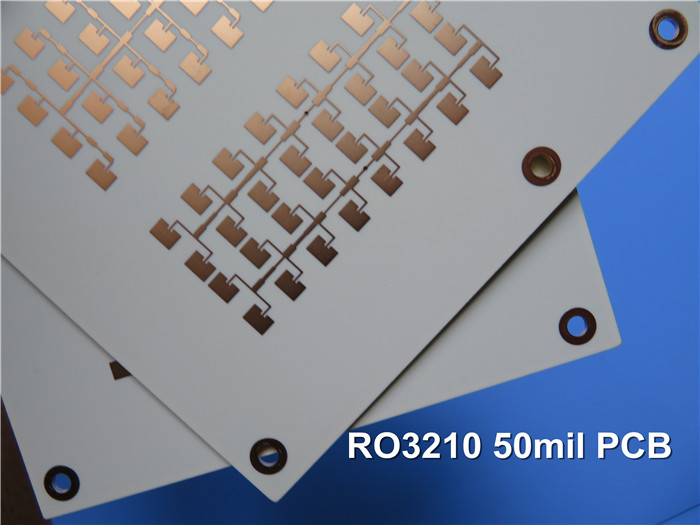

Rogers RF PCBs Built on RO3210 50mil, 1.27mm, DK10.2 with Immersion Gold for Microstrip Patch Antennas

(Printed Circuit Boards are custom-made products; the images and parameters shown are for reference only)

Rogers RO3210 high-frequency circuit materials consist of ceramic-filled laminates reinforced with woven fiberglass. These advanced materials are designed to deliver exceptional electrical performance and mechanical stability.

Today, we will discuss the RO3210 high frequency PCBs.

RO3210 high frequency circuit laminates are ceramic-filled materials reinforced with woven fiberglass. This material is an extension of the RO3000 series, featuring one key advantage—enhanced mechanical stability.

Typical Applications:

1.Automotive Collision Avoidance Systems

2.Automotive Global Positioning Satellite Antennas

3.Base Station Infrastructure

4.Datalink on Cable Systems

5.Direct Broadcast Satellite

6.LMDS and Wireless Broadband

7.Microstrip Patch Antennas for Wireless Communications

8.Power Backplanes

9.Remote Meter Readers

10.Wireless Telecommunications Systems

Our PCB Capabilities:

Rogers RO3210 50mil 1.27mm High Frequency PCB for Microstrip Patch Antennas |

|

PCB SIZE |

102 x 102mm=1PCS |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

YES |

LAYER STACKUP |

copper ------- 18µm(0.5 oz)+plate TOP layer |

RO3210 1.270mm |

|

copper ------- 18µm(0.5 oz)+plate BOT layer |

|

TECHNOLOGY |

|

Minimum Trace and Space: |

6 mil / 4 mil |

Minimum / Maximum Holes: |

0.4 mm / 2.5 mm |

Number of Different Holes: |

8 |

Number of Drill Holes: |

32 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

NO |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

RO3210 1.270mm |

Final foil external: |

1 oz |

Final foil internal: |

1 oz |

Final height of PCB: |

1.3 mm ±10% |

PLATING AND COATING |

|

Surface Finish |

Immersion gold |

Solder Mask Apply To: |

N/A |

Solder Mask Color: |

N/A |

Solder Mask Type: |

N/A |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

N/A |

Colour of Component Legend |

N/A |

Manufacturer Name or Logo: |

N/A |

VIA |

Plated through hole(PTH), minimum size 0.4mm. |

FLAMIBILITY RATING |

UL 94-V0 Approval MIN. |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

.jpg)

Data Sheet of RO3210

Property |

Typical Value RO3210 |

Direction |

Unit |

Condition |

Test Method |

Dielectric Constant, er Process |

10.2± 0.50 |

Z |

- |

10 GHz 23°C |

IPC-TM-650 2.5.5.5 |

Dielectric Constant, er Design |

10.8 |

Z |

- |

8 GHz - 40 GHz |

Differential Phase Length Method |

Dissipation Factor, tan d |

0.0027 |

Z |

- |

10 GHz 23°C |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of er |

-459 |

Z |

ppm/°C |

10 GHz 0-100°C |

IPC-TM-650 2.5.5.5 |

Dimensional Stability |

0.8 |

X,Y |

mm/m |

COND A |

ASTM D257 |

Volume Resistivity |

103 |

|

MW•cm |

COND A |

IPC 2.5.17.1 |

Surface Resistivity |

103 |

|

MW |

COND A |

IPC 2.5.17.1 |

Tensile Modulus |

579 |

MD CMD |

kpsi |

23°C |

ASTM D638 |

Water Absorption |

<0.1 |

- |

% |

D24/23 |

IPC-TM-650 2.6.2.1 |

Specific Heat |

0.79 |

|

J/g/K |

|

Calculated |

Thermal Conductivity |

0.81 |

- |

W/m/K |

80°C |

ASTM C518 |

Coefficient of Thermal Expansion (-55 to 288 °C) |

13 |

X,Y, Z |

ppm/°C |

23°C/50% RH |

IPC-TM-650 2.4.41 |

Td |

500 |

|

°C |

TGA |

ASTM D3850 |

Color |

Off White |

|

|

|

|

Density |

3.0 |

|

gm/cm3 |

|

|

Copper Peel Strength |

11.0 |

|

pli |

1 oz. EDC |

IPC-TM-2.4.8 |

Flammability |

V-0 |

|

|

|

UL 94 |

Lead Free Process Compatible |

YES |

|

|

|

|