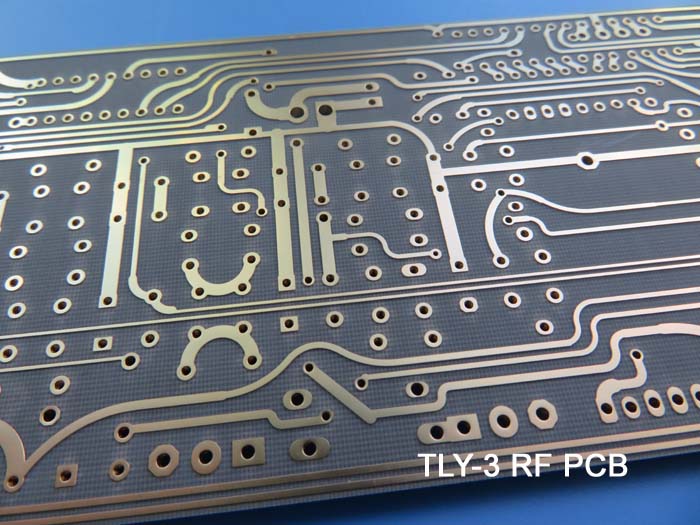

Taconic TLY-3 High-Frequency PCB, 30mil 0.762mm, Microwave Circuit Board with Immersion Gold

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

In the rapidly advancing field of electronics, high-frequency PCBs are essential for enabling cutting-edge technologies. The Taconic TLY-3 High-Frequency PCB, with a thickness of 30mil (0.762mm), is a standout choice for engineers and designers working on RF and microwave applications. This double-sided PCB, featuring immersion gold surface finish, is designed to deliver exceptional performance in demanding environments.

Key Features of Taconic TLY-3 PCB

1.Low Dielectric Constant (DK2.17 - 2.20): The TLY-3 material is optimized for high-frequency applications, ensuring minimal signal loss and superior performance in RF and microwave circuits. Its low DK makes it ideal for applications requiring high signal integrity.

2.Low Dissipation Factor (0.0009): The TLY-3 PCB ensures efficient signal transmission, making it suitable for applications that require high signal integrity, such as 5G and satellite communications.

3.Immersion Gold Surface Finish: The immersion gold finish provides excellent conductivity, corrosion resistance, and solderability, ensuring long-term reliability in harsh environments.

4.Dimensionally Stable: The woven fiberglass construction provides greater dimensional stability compared to chopped fiber-reinforced PTFE composites, making it suitable for high-volume manufacturing.

5.Low Moisture Absorption: The TLY-3 material has low moisture absorption, ensuring stable performance in various environmental conditions.

6.High Copper Peel Strength: The material offers high copper peel strength, ensuring reliable performance in high-stress applications.

.jpg)

PCB Specifications

Taconic TLY-3 30mil 0.762mm RF Antenna PCB DK2.33 High Frequency PCB for Satellite / Cellular Communications |

|

PCB SIZE |

100 x 90mm=1PCS |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

NO |

LAYER STACKUP |

copper ------- 18um(0.5 oz)+plate TOP layer |

TLY-3 0.762mm |

|

copper ------- 18um(0.5 oz) + plate BOT Layer |

|

TECHNOLOGY |

|

Minimum Trace and Space: |

4 mil / 4 mil |

Minimum / Maximum Holes: |

0.4mm |

Number of Different Holes: |

1 |

Number of Drill Holes: |

1 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

TLY-3 0.762mm |

Final foil external: |

1oz |

Final foil internal: |

N/A |

Final height of PCB: |

0.8 mm ±0.1 |

PLATING AND COATING |

|

Surface Finish |

Immersion gold (31%) |

Solder Mask Apply To: |

NO |

Solder Mask Color: |

N/A |

Solder Mask Type: |

N/A |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

Top Side |

Colour of Component Legend |

white |

Manufacturer Name or Logo: |

Marked on the board in a conductor and legend FREE AREA |

VIA |

N/A |

FLAMIBILITY RATING |

UL 94-V0 Approval MIN. |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

Applications

The Taconic TLY-3 PCB is well-suited for a variety of high-frequency and high-power applications, including:

1.Automotive Radar: Ideal for 77 GHz automotive radar applications.

2.Satellite and Cellular Communications: Ensures reliable performance in space and terrestrial communication systems.

3.Power Amplifiers: Delivers efficient power handling and signal integrity.

4.LNBs, LNAs, and LNCs: Suitable for low-noise block downconverters, low-noise amplifiers, and low-noise converters.

5.Aerospace Applications: Provides stable performance in aerospace environments.

6.Ka, E, and W Band Applications: Ensures precise signal transmission in millimeter-wave frequencies.

Why Choose Taconic TLY-3?

Proven Performance: With a low dielectric constant and low dissipation factor, the TLY-3 PCB is designed to meet the demands of high-frequency and high-power applications.

Thermal Stability: Its thermal properties ensure reliable performance even under extreme conditions, making it a trusted choice for engineers.

Versatility: Available in multiple thicknesses and customizable to specific design needs, the TLY-3 PCB is suitable for a wide range of applications.

Global Availability: Ready to ship worldwide, ensuring timely delivery for your projects.

Data Sheet of Taconic TLY Material

TLY TYPICAL VALUES |

|||||

Property |

Test Method |

Unit |

Value |

Unit |

Value |

DK at 10 GHz |

IPC-650 2.5.5.5 |

|

2.2 |

|

2.2 |

Df at 10 GHz |

IPC-650 2.5.5.5 |

|

0.0009 |

|

0.0009 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.02 |

% |

0.02 |

Dielectric Breakdown |

IPC-650 2.5.6 |

kV |

>45 |

kV |

>45 |

Dielectric Strength |

ASTM D 149 |

V/mil |

2,693 |

V/mil |

106,023 |

Volume Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms/cm |

1010 |

Mohms/cm |

1010 |

Volume Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms/cm |

1010 |

Mohms/cm |

109 |

Surface Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms |

108 |

Mohms |

108 |

Surface Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms |

108 |

Mohms |

108 |

Flex Strength(MD) |

IPC-650 2.4.4 |

psi |

14,057 |

N/mm2 |

96.91 |

Flex Strength(CD) |

IPC-650 2.4.4 |

psi |

12,955 |

N/mm2 |

89.32 |

Peel Stength(½ oz.ed copper) |

IPC-650 2.4.8 |

Ibs./inch |

11 |

N/mm |

1.96 |

Peel Stength(1 oz.CL1 copper) |

IPC-650 2.4.8 |

Ibs./inch |

16 |

N/mm |

2.86 |

Peel Stength(1 oz..CV1 copper) |

IPC-650 2.4.8 |

Ibs./inch |

17 |

N/mm |

3.04 |

Peel Stength |

IPC-650 2.4.8(after elevated temp.) |

Ibs./inch |

13 |

N/mm |

2.32 |

Young's Modulus(MD) |

ASTM D 3039/IPC-650 2.4.19 |

psi |

1.4 x 106 |

N/mm2 |

9.65 x 103 |

Poisson's Ratio(MD) |

ASTM D 3039/IPC-650 2.4.19 |

|

0.21 |

|

0.21 |

Thermal Conductivity |

ASTM F 433 |

W/M*K |

0.22 |

W/M*K |

0.22 |

Dimensional Stability(MD,10mil) |

IPC-650 2.4.39(avg.after bake&thermal stress) |

mils/inch |

-0.038 |

|

-0.038 |

Dimensional Stability(CD,10mil) |

IPC-650 2.4.39(avg.after bake&thermal stress) |

mils/inch |

-0.031 |

|

-0.031 |

Density(Specific Gravity) |

ASTM D 792 |

g/cm3 |

2.19 |

g/cm3 |

2.19 |

CTE(X axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

26 |

ppm/℃ |

26 |

CTE(Y axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

15 |

ppm/℃ |

15 |

CTE(Z axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

217 |

ppm/℃ |

217 |

NASA Outgassing(% TML) |

|

|

0.01 |

|

0.01 |

NASA Outgassing(% CVCM) |

|

|

0.01 |

|

0.01 |

NASA Outgassing(% WVR) |

|

|

0.00 |

|

0.00 |

UL-94 Flammability Rating |

UL-94 |

|

V-0 |

|

V-0 |